Infiniti QX56 (Z62). Manual - part 406

DLK-90

< DTC/CIRCUIT DIAGNOSIS >

B2417 TOUCH SENSOR LH

B2417 TOUCH SENSOR LH

DTC Logic

INFOID:0000000006225888

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON.

2.

Check “Self Diagnostic Result” mode of “AUTOMATIC BACK DOOR CONTROL UNIT” using CONSULT-

III.

Is DTC detected?

YES

>> Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000006225889

1.

CHECK HALF LATCH SWITCH SIGNAL

1.

Select “AUTOMATIC BACK DOOR CONTROL UNIT” using CONSULT-III.

2.

Select “TOUCH SEN LH” in “DATA MONITOR” mode.

3.

Check that the function operates normally according to the following conditions.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 2.

2.

CHECK TOUCH SENSOR INPUT SIGNAL

1.

Turn ignition switch OFF.

2.

Disconnect touch sensor LH connector.

3.

Check voltage between touch sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

CHECK TOUCH SENSOR LH CIRCUIT

1.

Disconnect automatic back door control module.

2.

Check continuity between automatic back door control module harness connector and touch sensor LH

harness connector.

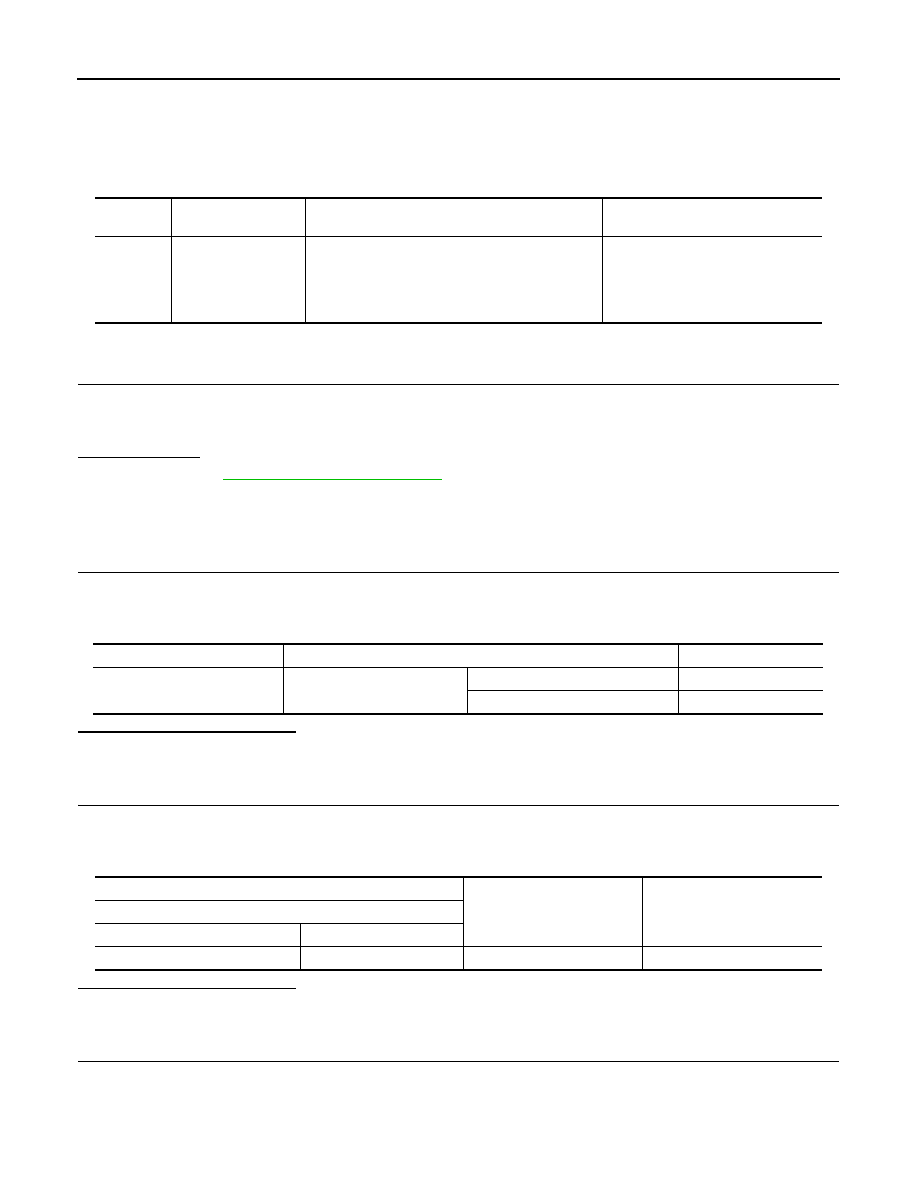

DTC

CONSULT-III display

description

DTC detecting condition

Possible cause

B2417

TOUCH SEN L

OPEN

When the automatic back door control unit detects

the open circuit of the touch sensor LH.

• Touch sensor LH

• Harness or connectors

(Touch sensor LH circuit is open)

• Automatic back door control mod-

ule

Monitor item

Condition

Status

TOUCH SEN LH

Touch sensor LH

Other than below

OFF

Detect obstruction

ON

(+)

(–)

Voltage

(Approx.)

Touch sensor LH

Connector

Terminal

D107

1

Ground

6 V