Infiniti QX56 (Z62). Manual - part 151

C1120, C1122, C1124, C1126 ABS IN VALVE SYSTEM

BRC-89

< DTC/CIRCUIT DIAGNOSIS >

[WITH VDC]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

YES

>> Perform trouble diagnosis for battery power supply. Refer to

PG-11, "Wiring Diagram - BATTERY

NO

>> Repair or replace error-detected parts.

3.

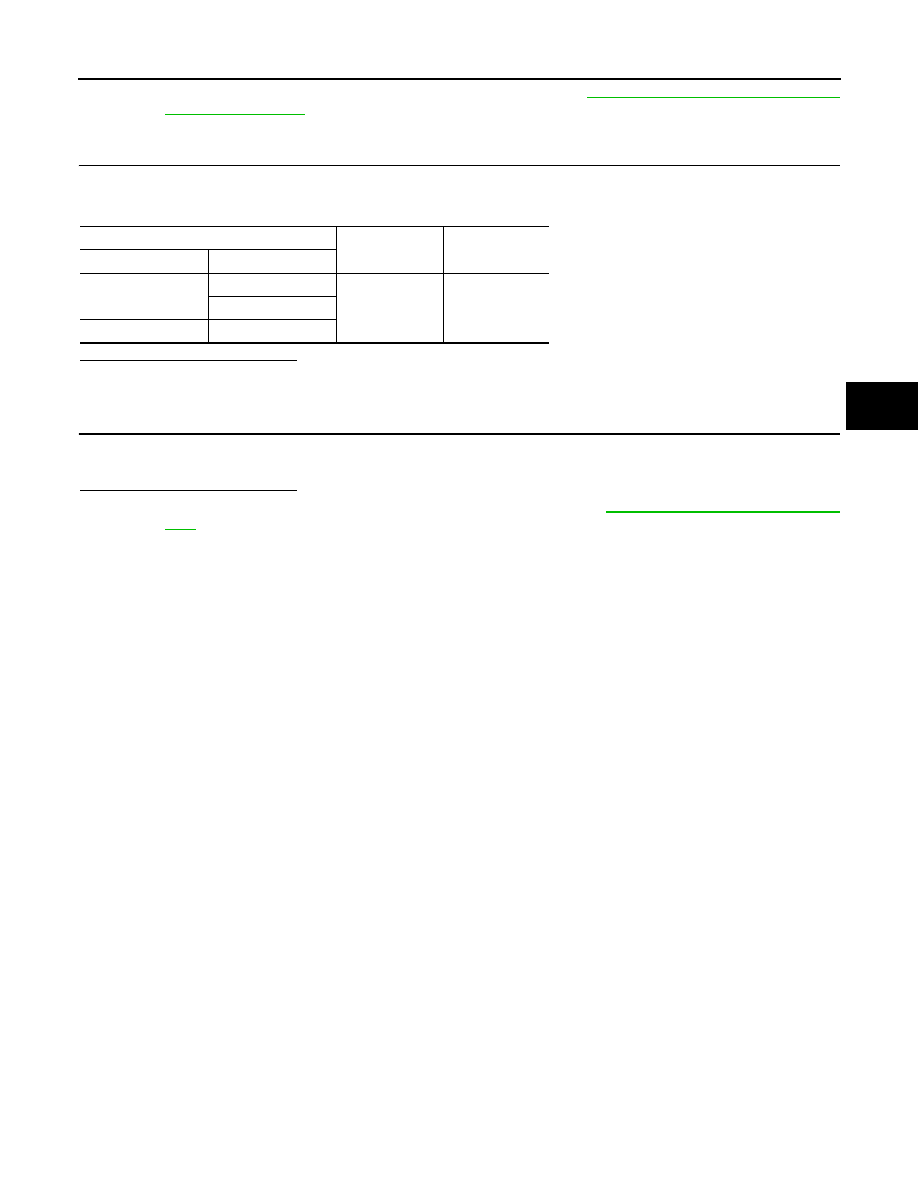

CHECK ABS IN VALVE GROUND CIRCUIT

1.

Turn the ignition switch OFF.

2.

Check continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK TERMINAL

Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness

connector.

Is the inspection result normal?

YES

>> Replace ABS actuator and electric unit (control unit). Refer to

BRC-137, "Removal and Installa-

.

NO

>> Repair or replace error-detected parts.

ABS actuator and electric unit (control unit)

—

Continuity

Connector

Terminal

E36

2

Ground

Existed

3

E37

48