Infiniti QX56 (Z62). Manual - part 138

SYSTEM

BRC-37

< SYSTEM DESCRIPTION >

[WITH VDC]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

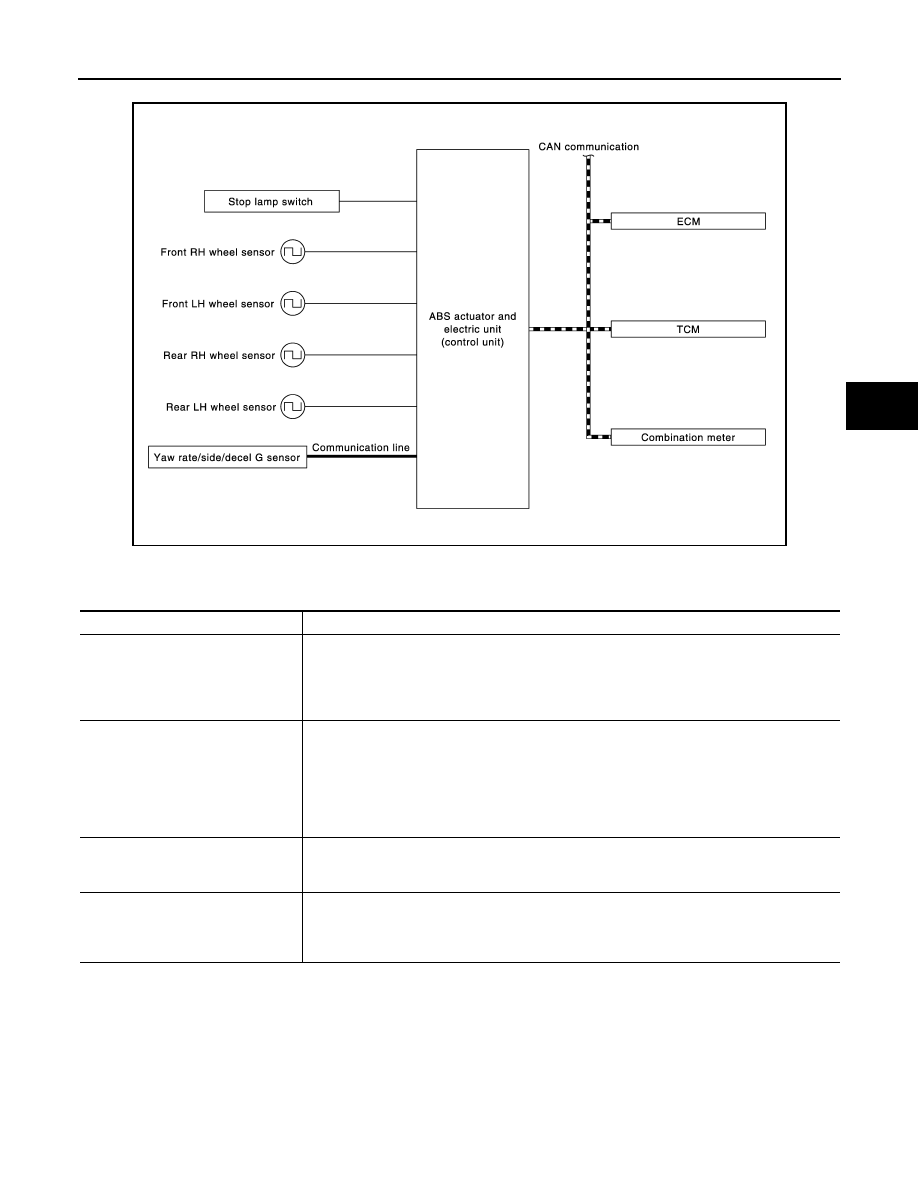

SYSTEM DIAGRAM

INPUT SIGNAL AND OUTPUT SIGNAL

Major signal transmission between each unit via communication lines is shown in the following table.

*: Communication line between yaw rate/side/decal G sensor and ABS actuator and electric unit (control unit)

BRAKE LIMITED SLIP DIFFERENTIAL (BLSD) FUNCTION

BRAKE LIMITED SLIP DIFFERENTIAL (BLSD) FUNCTION : System Description

INFOID:0000000006222577

• LH and RH driving wheel spin is always monitored. If necessary, appropriate brake force is independently

applied to LH or RH driving wheel so that one-sided wheel spin is avoided and traction is maintained. Mainly

starting ability is improved.

JPFIC0145GB

Component

Signal description

Yaw rate/side/decel G sensor

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via com-

munication line *.

• Yaw rate signal

• Side G sensor signal

• Decel G sensor signal

ECM

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Accelerator pedal position signal

• Engine speed signal

Mainly receives the following signals from ABS actuator and electric unit (control unit) via CAN

communication.

• Target throttle position signal

TCM

Mainly transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Shift position signal

Combination meter

Mainly receives the following signals from ABS actuator and electric unit (control unit) via CAN

communication.

• VDC warning lamp signal

• VDC OFF indicator lamp signal