Content .. 1095 1096 1097 1098 ..

Infiniti QX56 (Z62). Manual - part 1097

CHECK SHOCK ABSORBER FOR MALFUNCTION

SCS-25

< BASIC INSPECTION >

[HBMC]

C

D

F

G

H

I

J

K

L

M

A

B

SCS

N

O

P

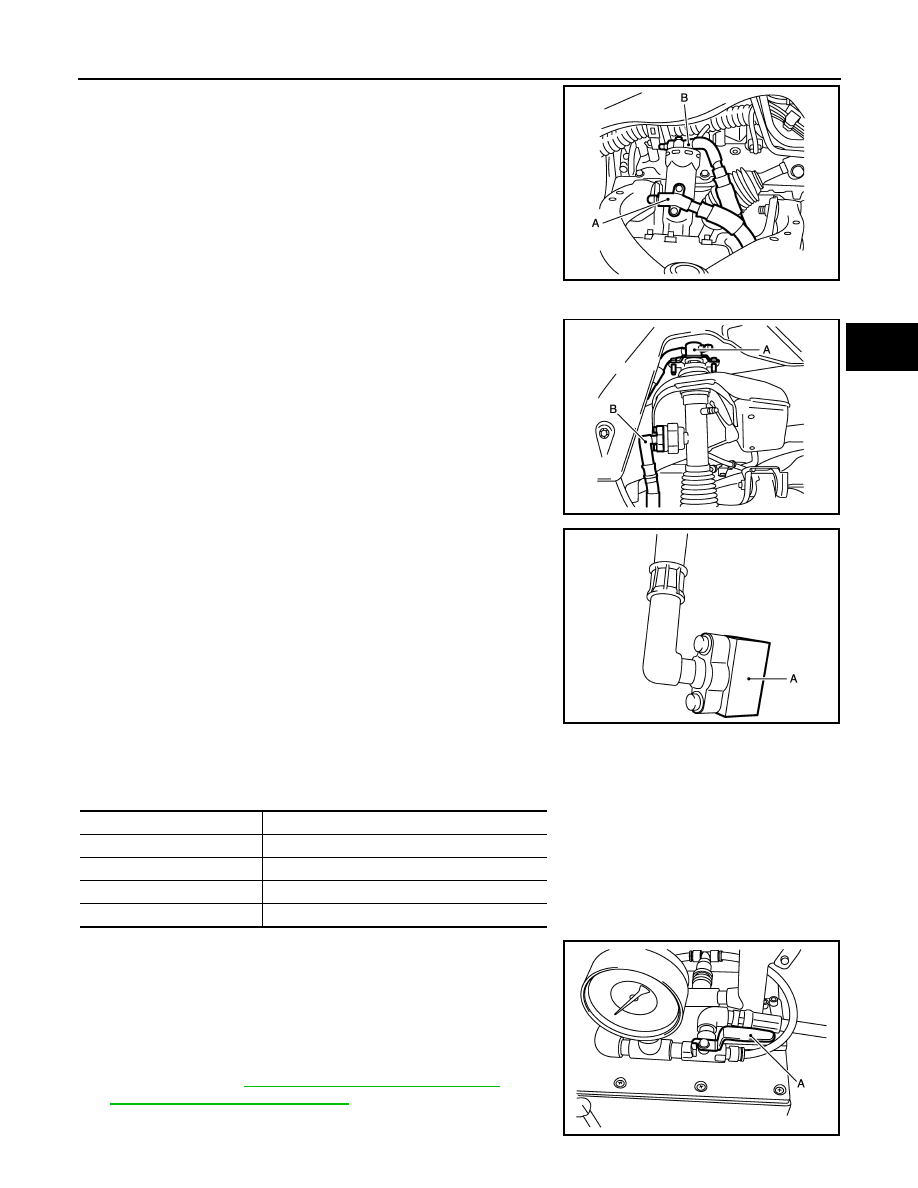

- Disconnect upper side pipe (B) of front shock absorber.

• For rear shock absorber

- Disconnect lower side pipe (B) of rear shock absorber.

9.

Install a leak check plug (SST: KV40108400) (A) to the removed

pipe and tighten the leak check plug to the specified torque.

CAUTION:

• O-ring must be free of scratches and damage.

• Piping must be kept free of the intrusion of dust and dirt.

10. Loosen lock nuts of needle valves B and D of PPMU and then

tighten needle valves B and D.

11. Loosening position of needle valve of PPMU varies according to

shock absorber that is checked. Loosen needle valve of PPMU

by approximately 2 rotations, as per the following table.

CAUTION:

Never loosen the needle valve more than required.

12. Set knob (A) of suspension oil pump to the direction as shown in

the figure.

13. Apply pressure of up to 2.4 MPa.

14. Go to step 15 when oil comes out from lower portion of shock

absorber which pipe is removed from. Go to step 16 when oil

does not come out.

15. Replace shock absorber, since shock absorber has internal

FSU-10, "Removal and Installation"

(front),

RSU-8, "Removal and Installation"

A

: Lower side pipe

JSEIA0233ZZ

A

: Upper side pipe

JSEIA0203ZZ

Tightening torque

: 5.0 N·m (0.51 kg-m, 44 in-lb)

Shock absorber

Loosening position of needle valve

Front LH

C

Rear LH

C

Front RH

A

Rear RH

A

JSEIA0210ZZ

JSEIA0191ZZ