Content .. 1031 1032 1033 1034 ..

Infiniti QX56 (Z62). Manual - part 1033

PWC-44

< DTC/CIRCUIT DIAGNOSIS >

ENCODER

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace harness.

3.

CHECK ENCORDER POWER SUPPLY

1.

Connect power window main switch connector.

2.

Turn ignition switch ON.

3.

Check voltage between front power window motor (driver side) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 4.

4.

CHECK ENCORDER POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect power window main switch connector.

3.

Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector.

4.

Check continuity between power window main switch harness connector and ground.

Is the inspection result normal?

YES

>> Replace power window main switch. Refer to

PWC-74, "Removal and Installation"

NO

>> Repair or replace harness.

5.

CHECK GROUND CIRCUIT 1

1.

Turn ignition switch OFF.

2.

Check continuity between front power window motor (driver side) harness connector and ground.

Is the inspection result normal?

YES

>> Replace front power window motor (driver side). Refer to

GW-21, "Removal and Installation"

.

NO

>> GO TO 6.

6.

CHECK GROUND CIRCUIT 2

1.

Disconnect power window main switch connector.

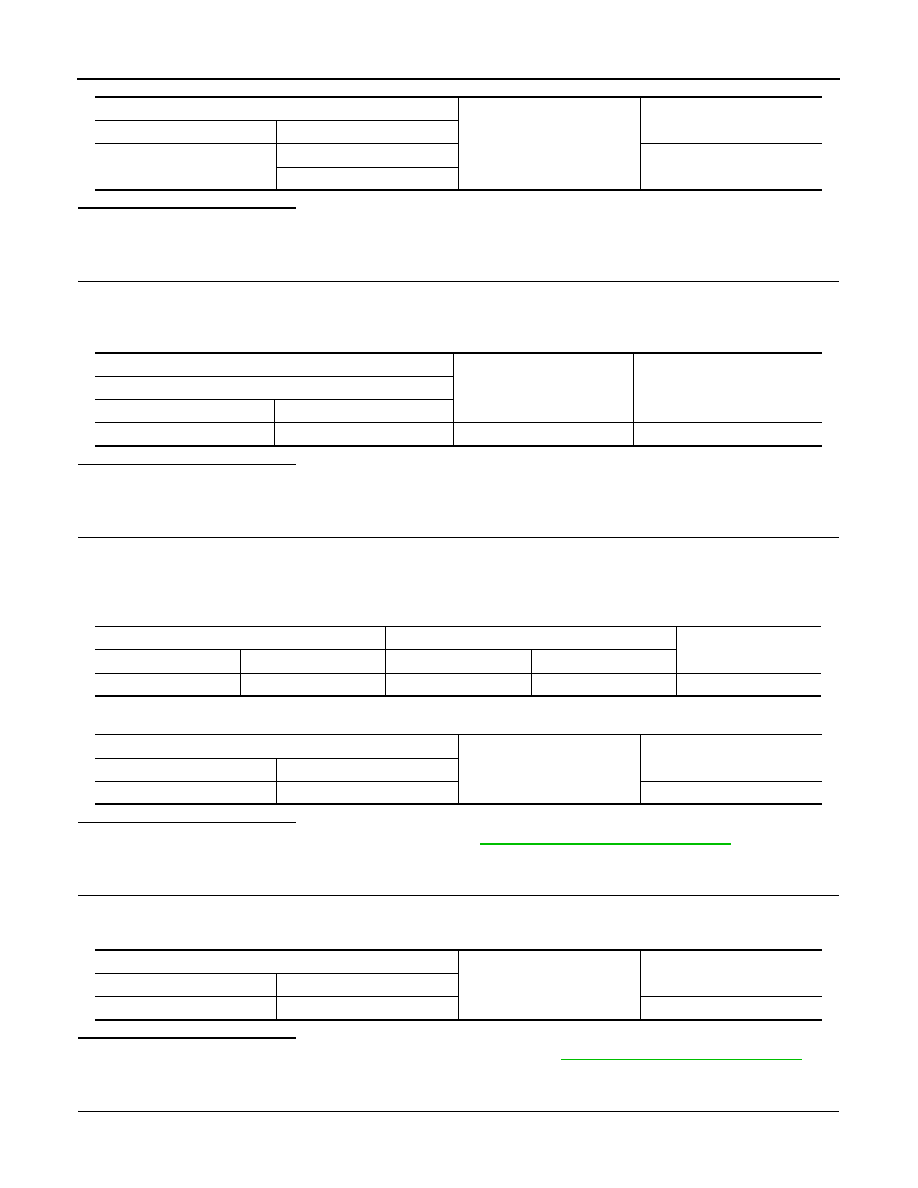

Power window main switch

Ground

Continuity

Connector

Terminal

D5

9

Not existed

13

(+)

(–)

Voltage (V)

(Approx.)

Front power window motor (driver side)

Connector

Terminal

D7

2

Ground

12

Power window main switch

Front power window motor (driver side)

Continuity

Connector

Terminal

Connector

Terminal

D5

15

D7

2

Existed

Power window main switch

Ground

Continuity

Connector

Terminal

D5

15

Not existed

Front power window motor (driver side)

Ground

Continuity

Connector

Terminal

D7

4

Existed