Infiniti Q45. Manual - part 900

LOW TIRE PRESSURE WARNING SYSTEM

WT-9

C

D

F

G

H

I

J

K

L

M

A

B

WT

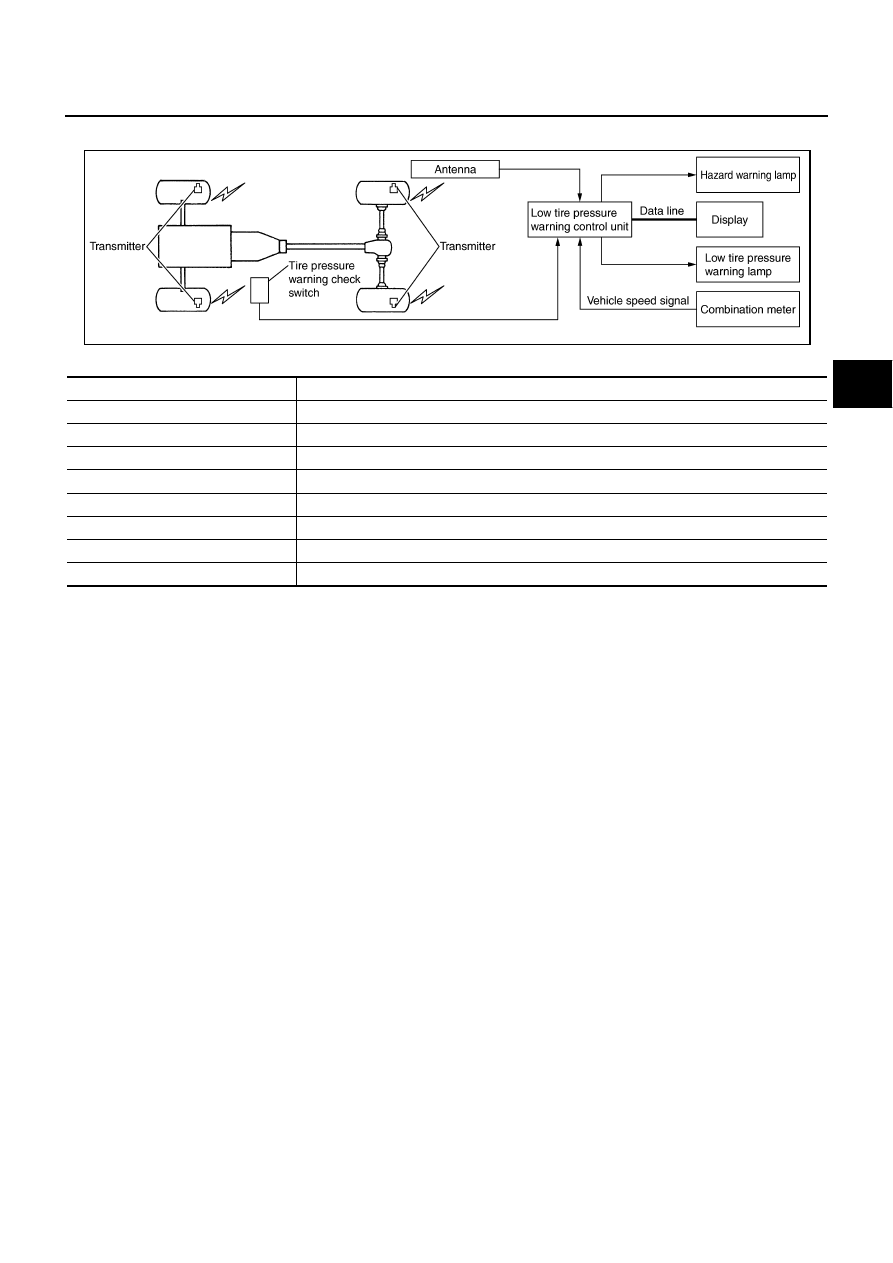

System Diagram

NES000CY

COMPONENTS FUNCTION DESCRIPTION

SEIA0741E

Component parts

Function

Low tire pressure warning control unit

Monitors tire pressure and controls the low tire pressure warning lamp and turn signal lamp.

Transmitter

Converts tire pressure signals to radio signals.

Antenna

Receives radio signals converted from tire pressure signals.

Display

Displays the air pressure of each tire.

Tire pressure warning check switch

Allows a mode to be switched to a diagnosis mode.

Hazard warning lamp

ID registration of each wheel has been completed, turn signal lamp flashes two times.

Combination meter

Transmitters the vehicle speed signal to low tire pressure warning control unit.

Low tire pressure warning lamp

Illuminates if malfunction is detected in electrical system of low tire pressure warning system.