Infiniti Q45. Manual - part 827

AUTOMATIC DRIVE POSITIONER

SE-63

C

D

E

F

G

H

J

K

L

M

A

B

SE

Check Sliding Sensor Circuit

NIS0012W

1.

CHECK SLIDING SENSOR MECHANISM

Check the operation malfunction caused by sliding rail deformation or parts are loose.

OK or NG

OK

>> GO TO 2.

NG

>> Repair the malfunctioning part and check again.

2.

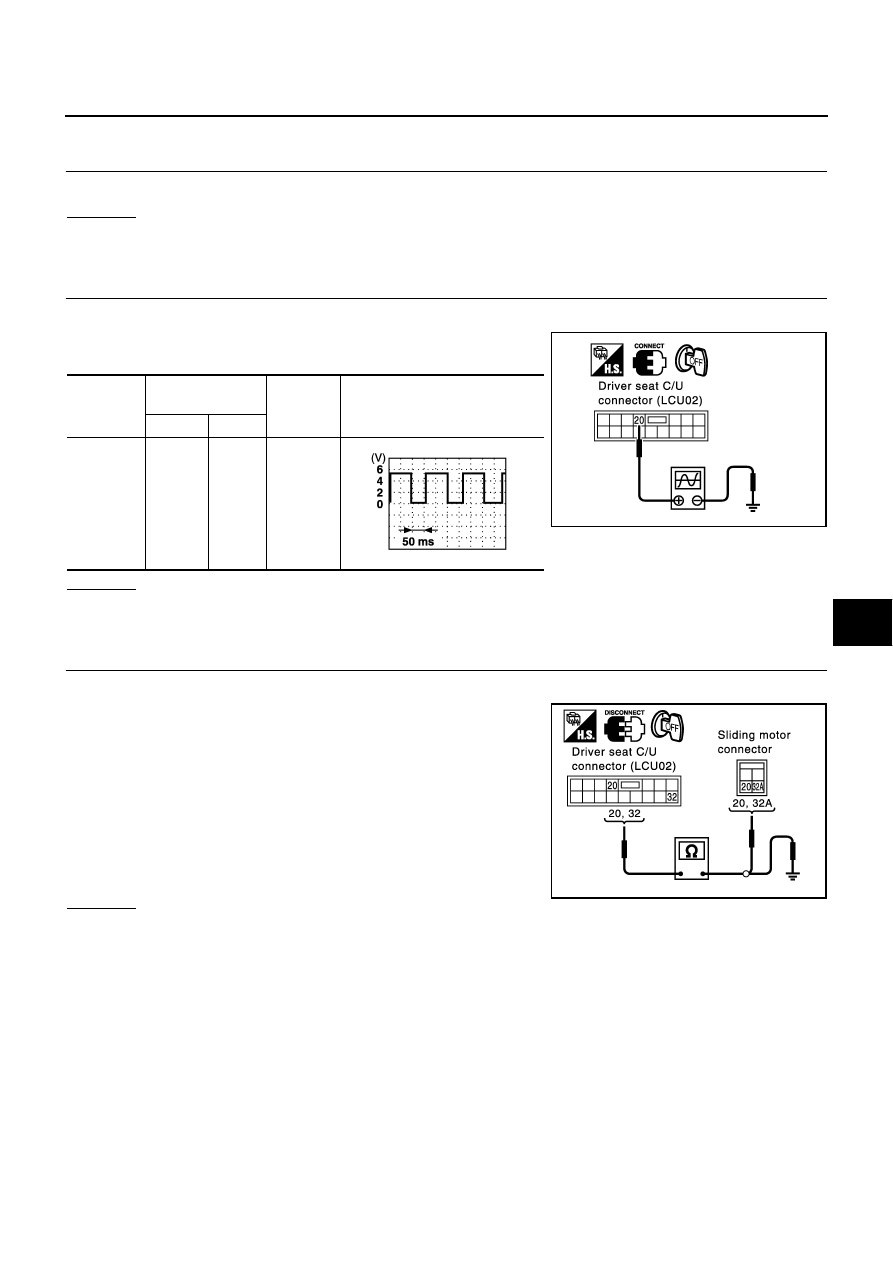

CHECK SLIDING SENSOR INPUT/OUTPUT SIGNAL

1.

Turn ignition switch OFF.

2.

Check signal between driver seat control unit connector and

ground, with oscilloscope.

OK or NG

OK

>> System is OK.

NG

>> GO TO 3.

3.

CHECK HARNESS CONTINUITY

1.

Disconnect driver seat control unit connector and sliding motor connector.

2.

Check continuity between driver seat control unit connector

B143 terminals 20, 32 and sliding motor B146 terminals 20, 32A.

3.

Check continuity between driver seat control unit B143 terminals

20, 32 and ground.

OK or NG

OK

>> Replace sliding motor.

NG

>> Repair or replace harness between driver seat control unit and sliding motor.

Connector

Terminals

(Wire color)

Condition

Signal

(Reference valve)

(+)

(–)

B143

20 (G/B)

Ground

Sliding

motor

operation

PIIA4130E

PIIA3277E

20 (G/B) – 20 (G/B)

: Continuity should exist.

32 (R/W) – 32A (R/W)

: Continuity should exist.

20 (G/B) – Ground

:Continuity should not exist.

32 (R/W) – Ground

:Continuity should not exist.

PIIA4129E