Infiniti Q45. Manual - part 776

PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

M

A

B

RSU

PREPARATION

PFP:00002

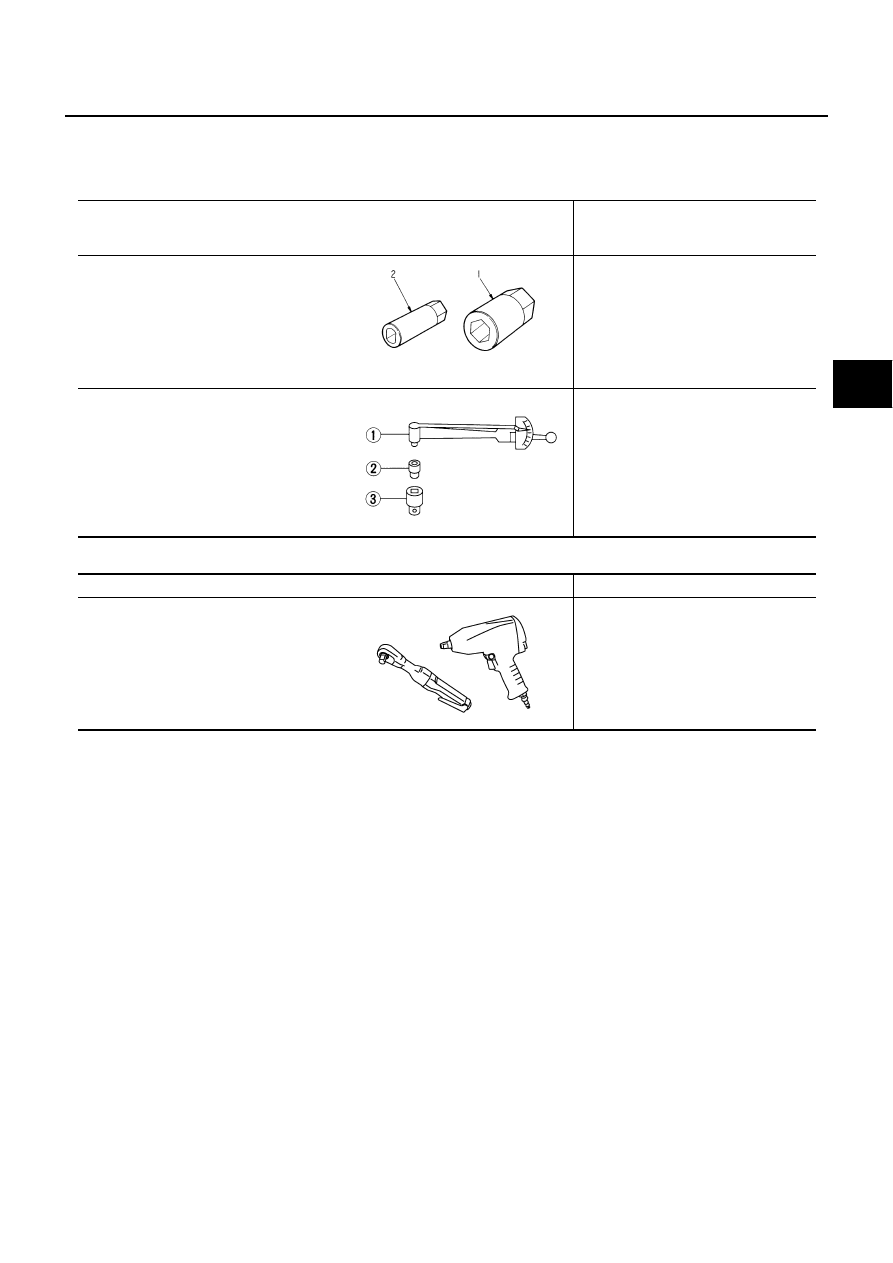

Special Service Tools (SST)

NES0006H

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

NES0006I

Tool number

(Kent-Moore No.)

Tool name

Description

KV40106400

(

—

)

Socket wrench

Removing actuator plate fixing nut

(with active damper suspension)

ST3127S000

(See J

−

25765-A)

Preload gauge

1. GG91030000

Torque wrench (J

−

25765)

2. HT62940000 ( — )

Socket adapter (1/2

″

)

3. HT62900000 ( — )

Socket adapter (3/8

″

)

Measuring rotating torque of ball joint

ZZA1102D

NT124

Tool name

Description

Power tool

●

Removing wheel nuts

●

Removing brake caliper

●

Removing suspension component

parts

PBIC0190E