Infiniti Q45. Manual - part 599

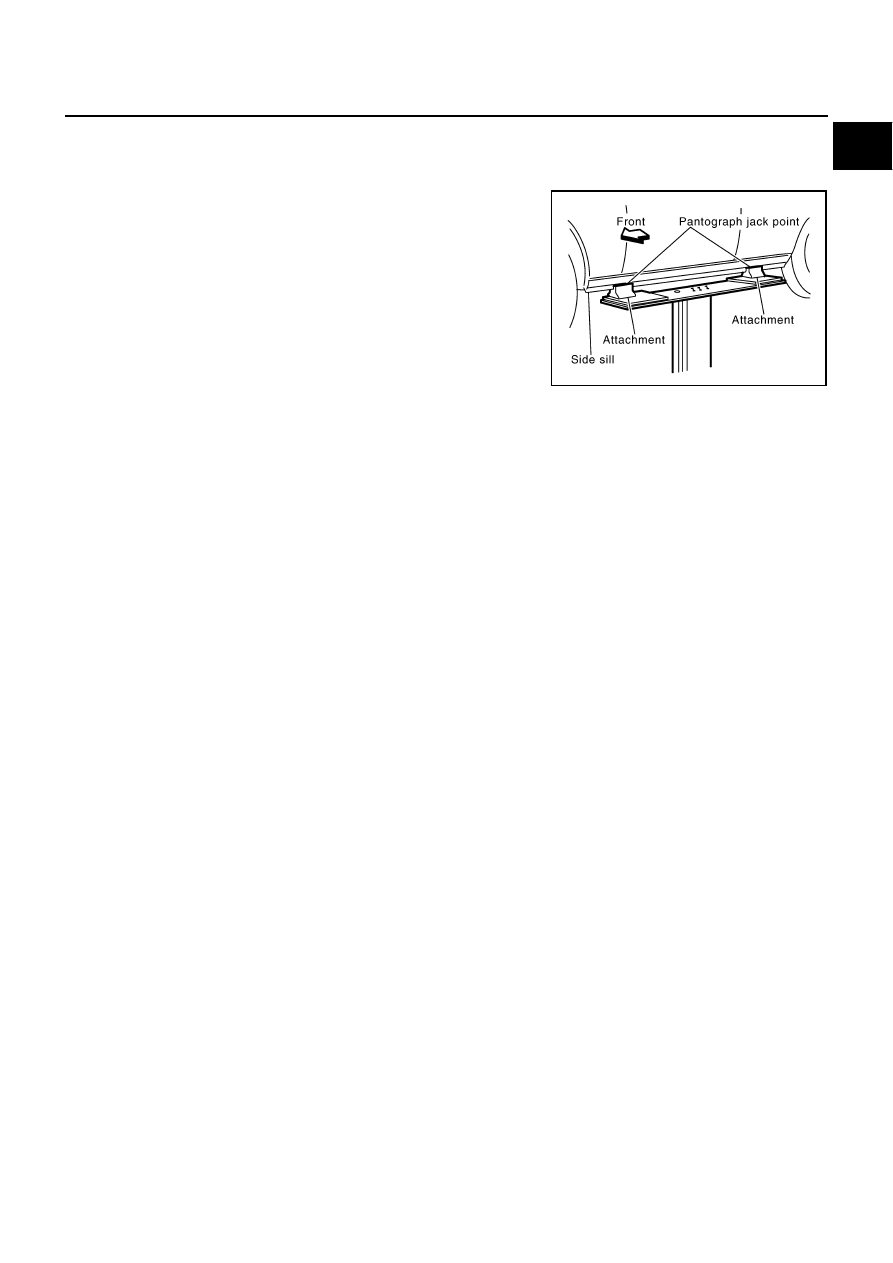

LIFTING POINT

GI-41

C

D

E

F

G

H

I

J

K

L

M

B

GI

Board-on Lift

NAS0004B

CAUTION:

Make sure vehicle is empty when lifting.

●

The board-on lift attachment set at front end of vehicle

should be set on the front of the sill under the front door

opening.

●

Position attachments at front and rear ends of board-on lift.

PIIB7445E