Infiniti Q45. Manual - part 560

CAMSHAFT

EM-57

C

D

E

F

G

H

I

J

K

L

M

A

EM

3.

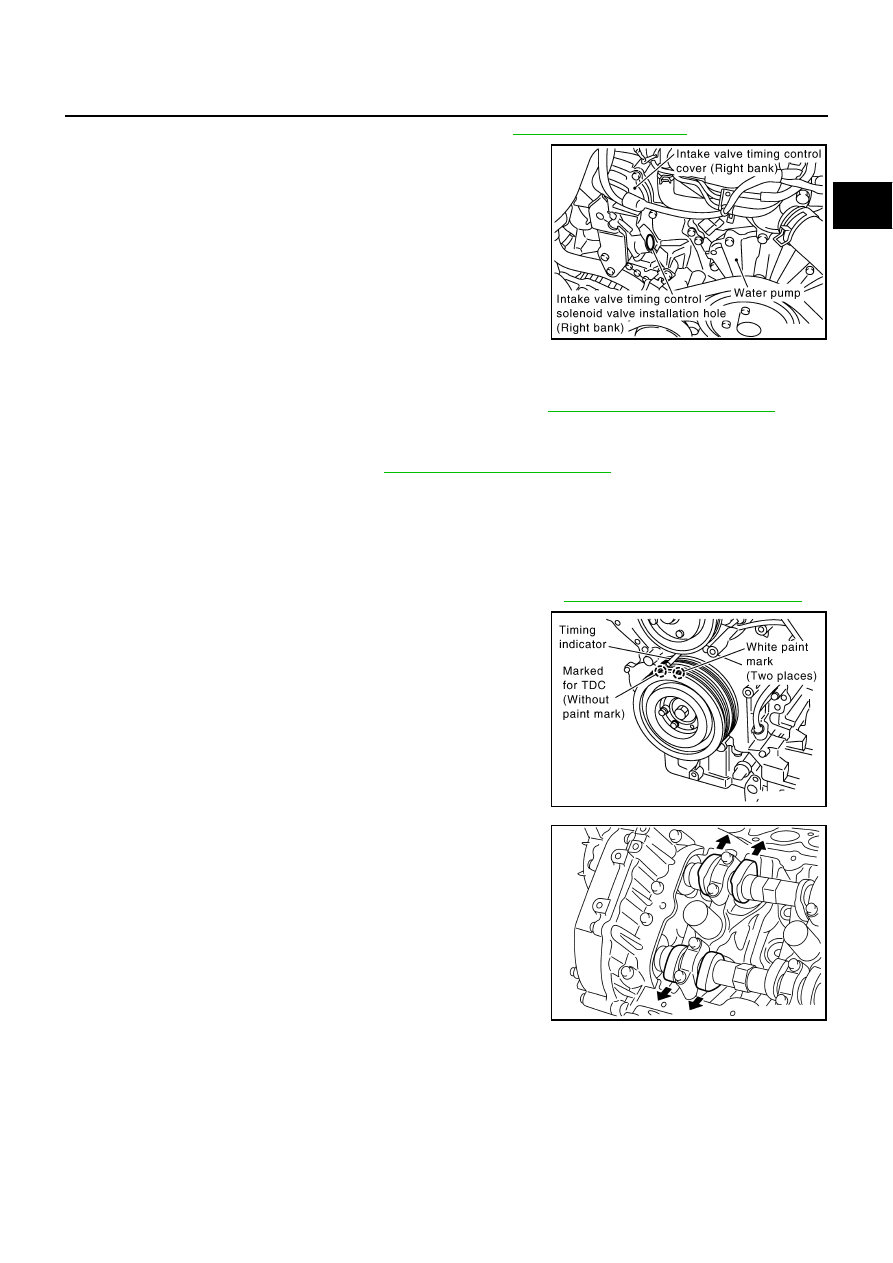

Remove intake valve timing control solenoid valve. Refer to

.

4.

Crank the engine, and then make sure that engine oil comes out

from intake valve timing control cover oil hole. End crank after

checking.

WARNING:

Be careful not to touch rotating parts (drive belt, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Engine oil may squirt from intake valve timing control sole-

noid valve installation hole during cranking. Use a shop

cloth to prevent the engine components and the vehicle. Do

not allow engine oil to get on rubber components such as

drive belt or engine mount insulators. Immediately wipe off

any splashed engine oil.

●

Clean oil groove between oil strainer and intake valve timing control solenoid valve if engine oil does not

come out from intake valve timing control cover oil hole. Refer to

5.

Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

●

Clean oil groove if necessary. Refer to

6.

After inspection, install removed parts.

Valve Clearance

NBS001OT

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions due to changes in valve clearance (engine starting, idling, and/or noise).

1.

Remove rocker cover (right and left bank) with power tool. Refer to

EM-37, "Removal and Installation"

2.

Turn crankshaft pulley in normal direction (clockwise when

viewed from engine front) to align TDC identification notch (with-

out paint mark) with timing indicator.

3.

At this time, make sure that the both intake and exhaust cam

noses of No. 1 cylinder (top front on left bank) face outside.

●

If they do not face outside, turn crankshaft pulley by 360

degrees once more.

PBIC2848E

PBIC2341E

KBIA0400J