Infiniti Q45. Manual - part 552

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

C

D

E

F

G

H

I

J

K

L

M

A

EM

Exhaust Manifold

●

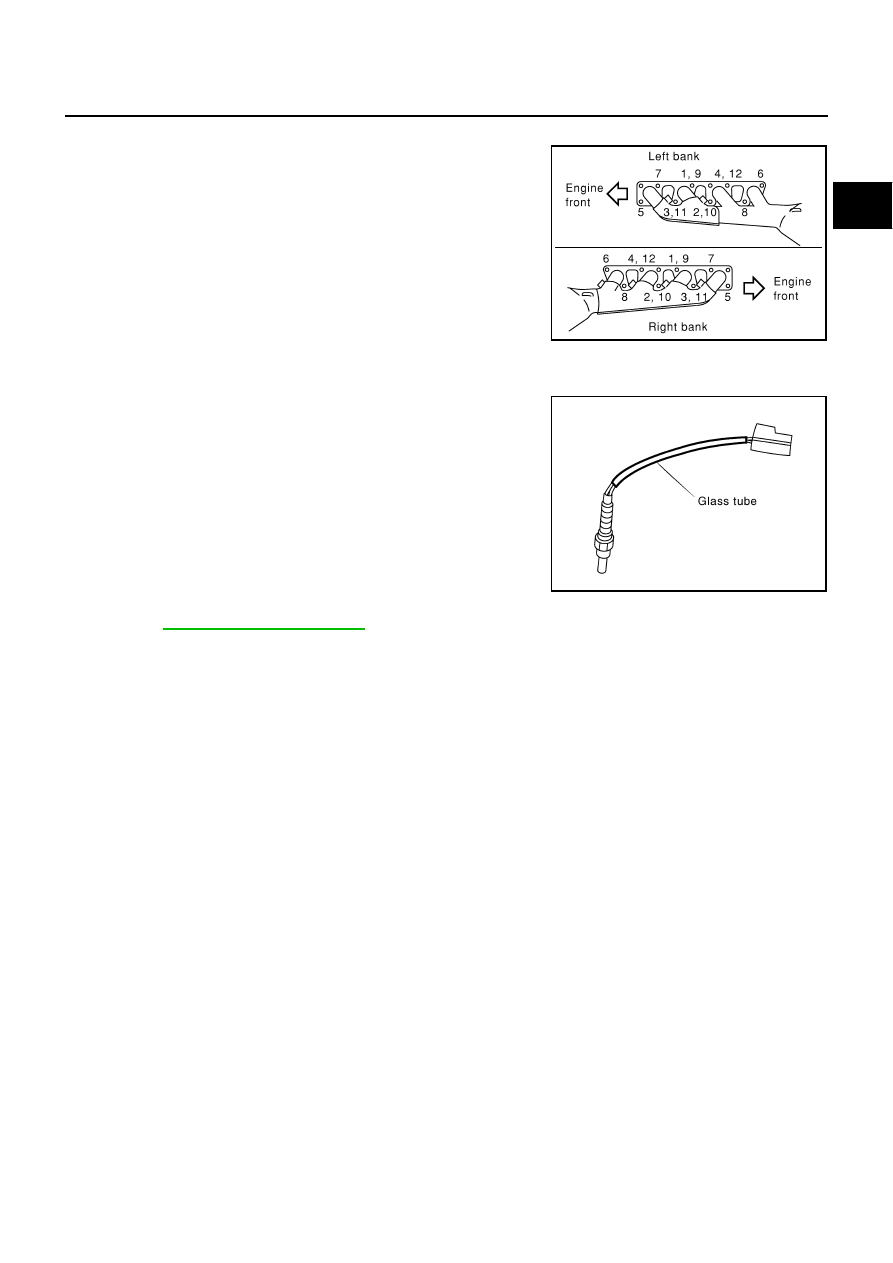

Install exhaust manifold and three way catalyst in numerical

order shown in the figure.

●

Tighten nuts No. 1 to No. 4 in two steps. Order No. 9 to 12

shows second step.

Air Fuel Ratio sensor 1 and Heated Oxygen Sensor 2

●

Install air fuel ratio sensor and heated oxygen sensors in the original position.

●

Install referring the following if the installation positions cannot

be identified.

*

1

: Length of bank1 for air fuel ratio sensor is different from

bank2.

*

2

: Refer to

CAUTION:

●

Before installing a new air fuel ratio sensor 1 and a new heated oxygen sensor 2, clean exhaust

system threads using the heated oxygen sensor thread cleaner (commercial service tool: J-43897-

18 or J-43897-12), and apply anti-seize lubricant (commercial service tool).

●

Do not over torque the air fuel ratio sensor 1 and heated oxygen sensor 2. Doing so may cause

damage to the air fuel ratio sensor 1 and heated oxygen sensor 2, resulting in the MIL coming on.

PBIC0022E

Glass tube color

Air fuel ratio sensor 1 (bank 1)*

1

: Black

Air fuel ratio sensor 1 (bank 2)*

1

: Black

Heated oxygen sensor 2 (bank 1)*

2

: White

Heated oxygen sensor 2 (bank 2)*

2

: White

PBIC2652E