Infiniti Q45. Manual - part 441

DTC P0442 EVAP CONTROL SYSTEM

EC-403

C

D

E

F

G

H

I

J

K

L

M

A

EC

21.

CHECK REFUELING EVAP VAPOR LINE

Check refuelling EVAP vapor line between EVAP canister and fuel tank for clogging, kink, looseness and

improper connection. For location, refer to

EC-38, "ON BOARD REFUELING VAPOR RECOVERY (ORVR)"

OK or NG

OK

>> GO TO 22.

NG

>> Repair or replace hoses and tubes.

22.

CHECK SIGNAL LINE AND RECIRCULATION LINE

Check signal line and recirculation line between filler neck tube and fuel tank for clogging, kink, cracks, loose-

ness and improper connection.

OK or NG

OK

>> GO TO 23.

NG

>> Repair or replace hose, tube or filler neck tube.

23.

CHECK REFUELING CONTROL VALVE

Refer to

OK or NG

OK

>> GO TO 24.

NG

>> Replace refueling EVAP vapor cut valve with fuel tank.

24.

CHECK FUEL LEVEL SENSOR

Refer to

DI-22, "CHECK FUEL LEVEL SENSOR UNIT"

.

OK or NG

OK

>> GO TO 25.

NG

>> Replace fuel level sensor unit.

25.

CHECK INTERMITTENT INCIDENT

Refer to

EC-145, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Component Inspection

NBS001X1

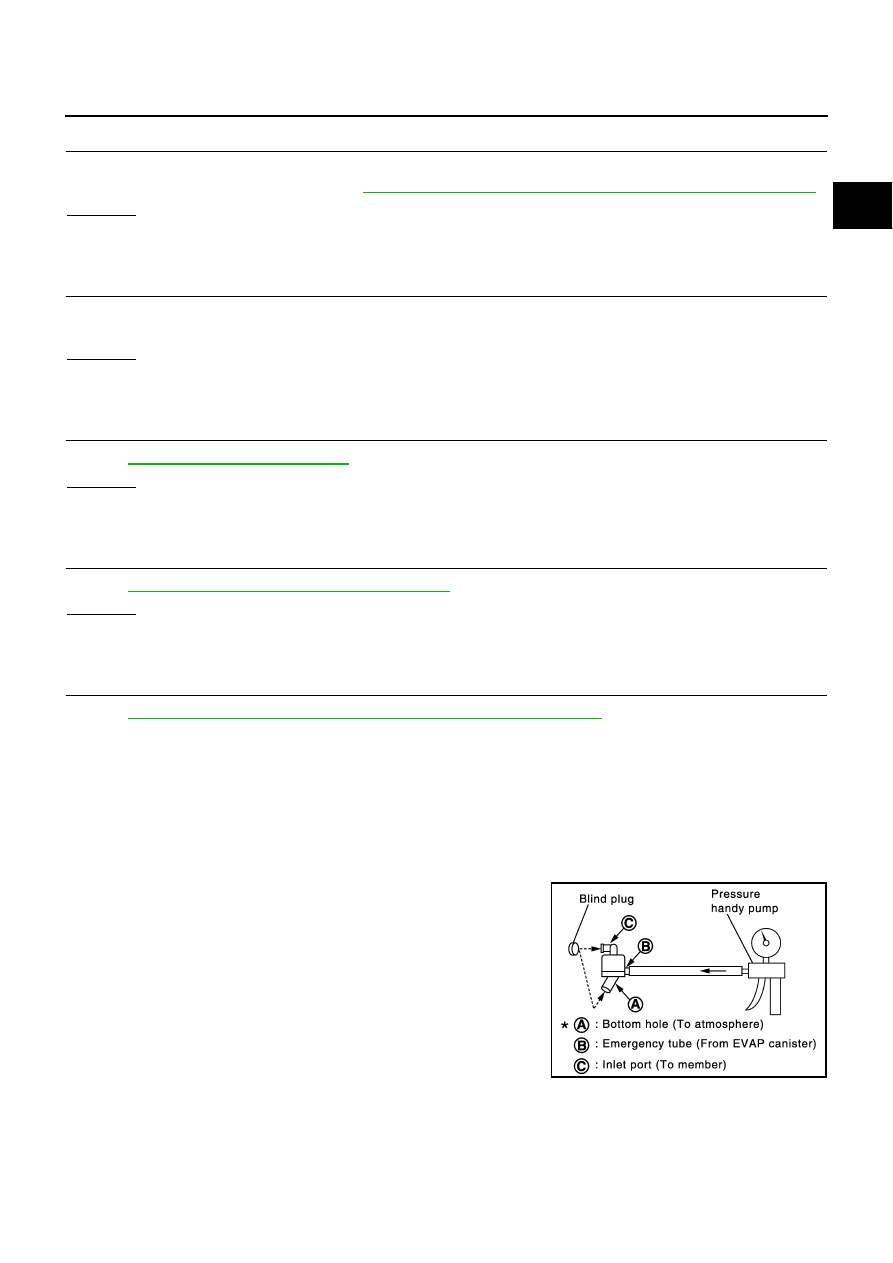

WATER SEPARATOR

1.

Check visually for insect nests in the water separator air inlet.

2.

Check visually for cracks or flaws in the appearance.

3.

Check visually for cracks or flaws in the hose.

4.

Check that A and C are not clogged by blowing air into B with

A , and then C plugged.

5.

In case of NG in items 2 - 4, replace the parts.

NOTE:

●

Do not disassemble water separator.

PBIB1032E