Infiniti Q45. Manual - part 385

DTC P0031, P0032, P0051, P0052 A/F SENSOR 1 HEATER

EC-179

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

CHECK A/F SENSOR 1 HEATER

Refer to

EC-179, "Component Inspection"

OK or NG

OK

>> GO TO 6.

NG

>> Replace malfunctioning air fuel ratio sensor 1.

6.

CHECK INTERMITTENT INCIDENT

Refer to

EC-145, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Component Inspection

NBS002WW

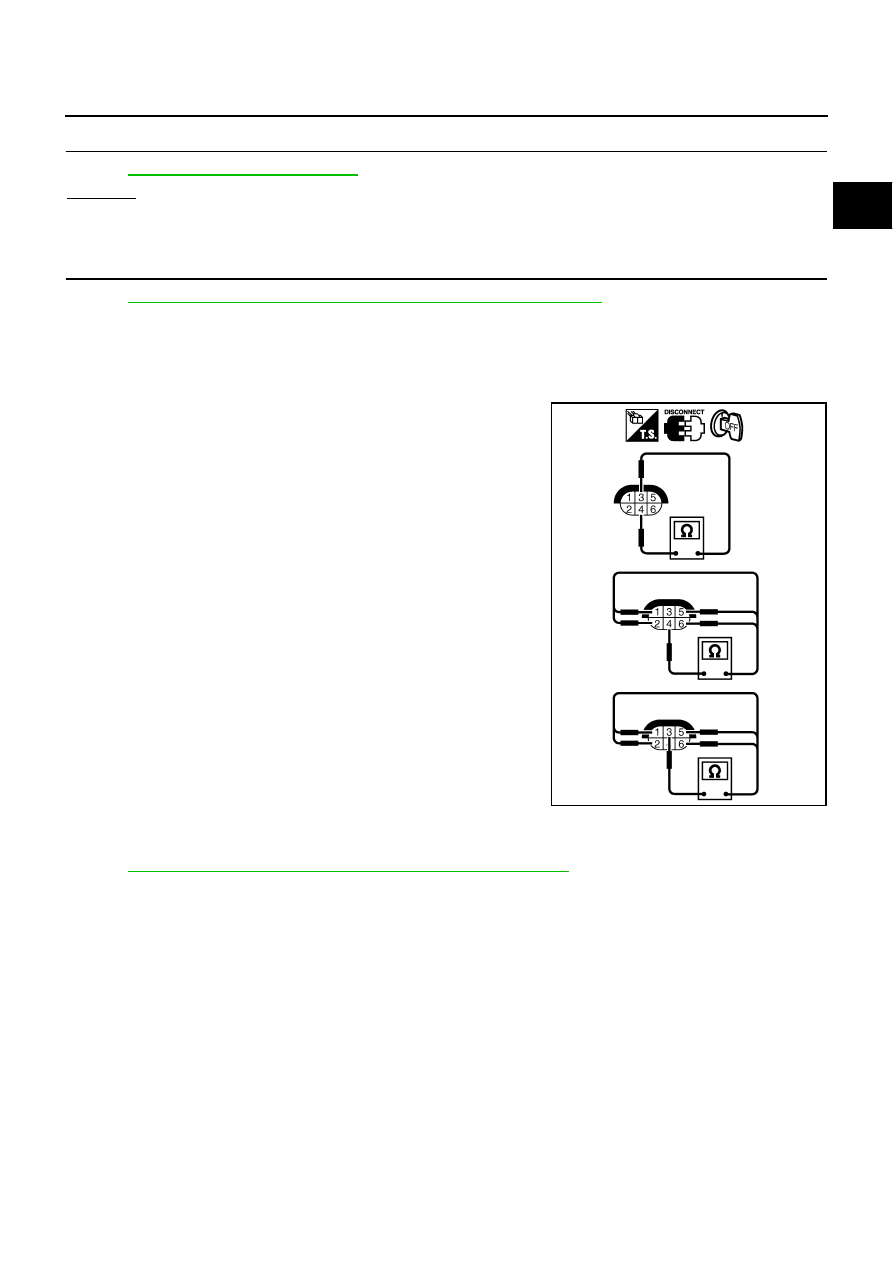

AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Check resistance between terminals 3 and 4.

Check continuity between terminals 3 and 1, 2, 5, 6, terminals 4 and

1, 2, 5, 6.

If NG, replace the A/F sensor 1.

CAUTION:

●

Discard any A/F sensor which has been dropped from a

height of more than 0.5 m (19.7 in) onto a hard surface such

as a concrete floor; use a new one.

●

Before installing new A/F sensor, clean exhaust system

threads using Heated Oxygen Sensor Thread Cleaner tool

J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Removal and Installation

NBS002WX

AIR FUEL RATIO (A/F) SENSOR 1

Refer to

EM-23, "EXHAUST MANIFOLD AND THREE WAY CATALYST"

Resistance: 2.3 - 4.3

Ω

[at 25

°

C (77

°

F)]

Continuity should not exist.

PBIB1684E