Infiniti Q45. Manual - part 349

EVAPORATIVE EMISSION SYSTEM

EC-35

C

D

E

F

G

H

I

J

K

L

M

A

EC

Component Inspection

NBS001QE

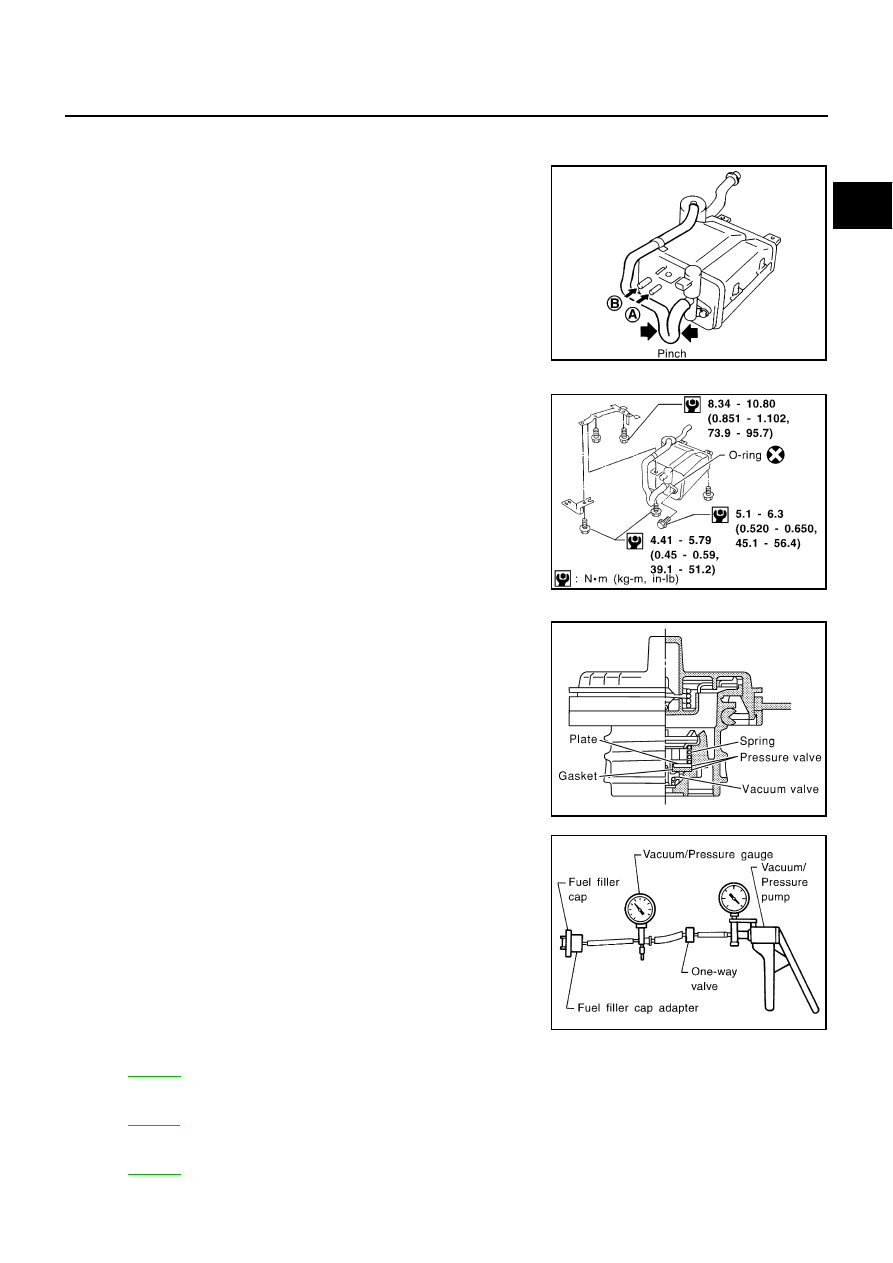

EVAP CANISTER

Check EVAP canister as follows:

1.

Pinch the fresh air hose.

2.

Blow air into port A and check that it flows freely out of port B .

Tightening Torque

Tighten EVAP canister as shown in the figure.

Make sure new O-ring is installed properly between EVAP can-

ister and EVAP canister vent control valve.

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FULLER CAP)

1.

Wipe clean valve housing.

2.

Check valve opening pressure and vacuum.

3.

If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may come on.

VACUUM CUT VALVE AND VACUUM CUT VALVE BYPASS VALVE

Refer to

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to

FUEL TANK TEMPERATURE SENSOR

Refer to

SEF396T

SEF397T

SEF445Y

Pressure:

15.3 - 20.0 kPa (0.156 - 0.204 kg/cm

2

, 2.22 -

2.90 psi)

Vacuum:

−

6.0 to

−

3.3 kPa (

−

0.061 to

−

0.034 kg/cm

2

,

−

0.87 to

−

0.48 psi)

SEF943S