Infiniti Q45. Manual - part 345

PRECAUTIONS

EC-19

C

D

E

F

G

H

I

J

K

L

M

A

EC

●

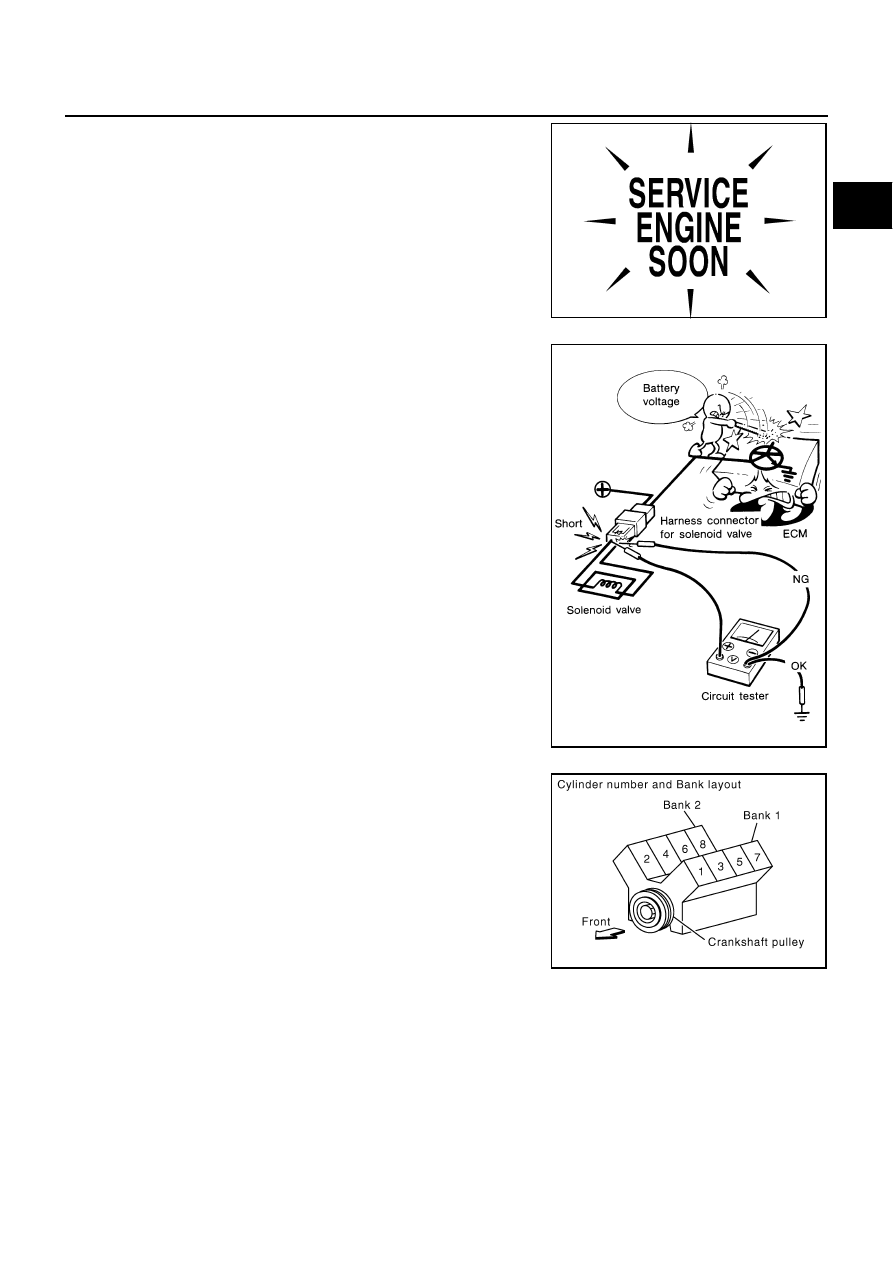

After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Overall Function

Check should be a good result if the repair is completed.

●

When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

●

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

●

B1 indicates the bank 1 and B2 indicates the bank 2 as

shown in the figure.

SEF217U

SEF348N

PBIB1144E