Infiniti Q45. Manual - part 260

PREPARATION

BRC-5

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

PREPARATION

PFP:00002

Special Service Tools

NFS000CH

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

NFS000CI

Tool number

(Kent-Moore No.)

Tool name

Description

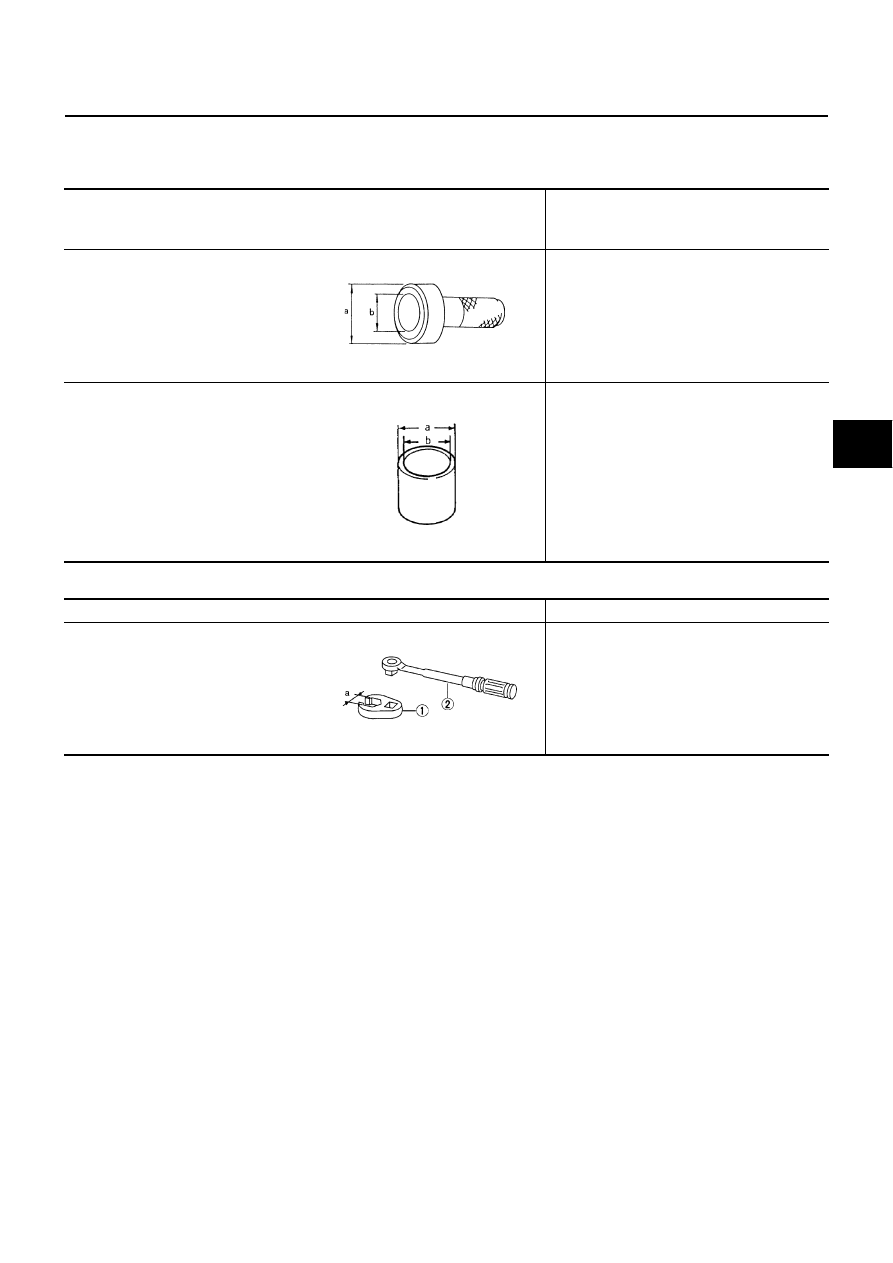

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.19 in) dia.

Installing rear sensor rotor.

ST27863000

(

—

)

Drift

a: 74.5 mm (2.93 in) dia.

b: 62.5 mm (2.46 in) dia.

KV40104710

(

—

)

Drift

a: 76.3 mm (3.00 in) dia.

b: 67.9 mm (2.67 in) dia.

Installing rear sensor rotor.

ZZC0760D

ZZA0832D

Tool name

Description

1.Flare nut crowfoot

a:10 mm (0.39 in)/12 mm (0.47 in)

2.Torque wrench

Removing and installing each brake piping

S-NT360