Infiniti Q45 (FY33). Manual - part 128

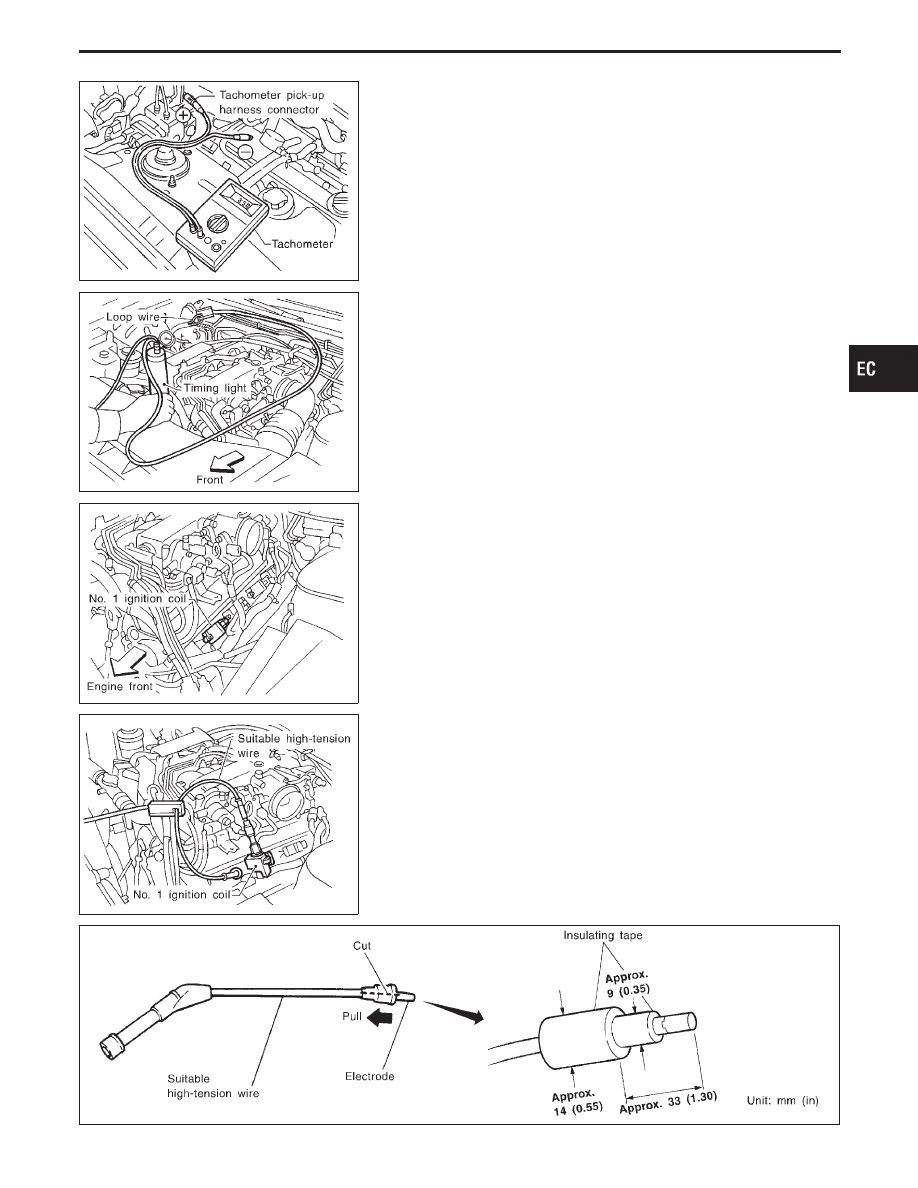

SEF553T

I

Method B (Using check connector)

Check the idle speed using check connector as shown in the fig-

ure. (Check connector is located in the harness protector).

SEF295T

IGNITION TIMING

Any of the following two methods may be used.

I

Method A

1.

Attach timing light to loop wire as shown.

2.

Check ignition timing.

SEF296T

I

Method B

1.

Remove intake air duct.

2.

Remove No. 1 ignition coil.

SEF297T

3.

Connect No. 1 ignition coil and No. 1 spark plug with suitable

high-tension wire as shown, and attach timing light clamp to

this wire.

4.

Install air duct.

5.

Check ignition timing.

SEF011V

GI

MA

EM

LC

FE

AT

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

BASIC SERVICE PROCEDURE

Direct Ignition System — How to Check Idle

Speed and Ignition Timing (Cont’d)

EC-41