Infiniti M45 (Y34). Manual - part 762

AUTOMATIC DRIVE POSITIONER

SE-69

C

D

E

F

G

H

J

K

L

M

A

B

SE

4.

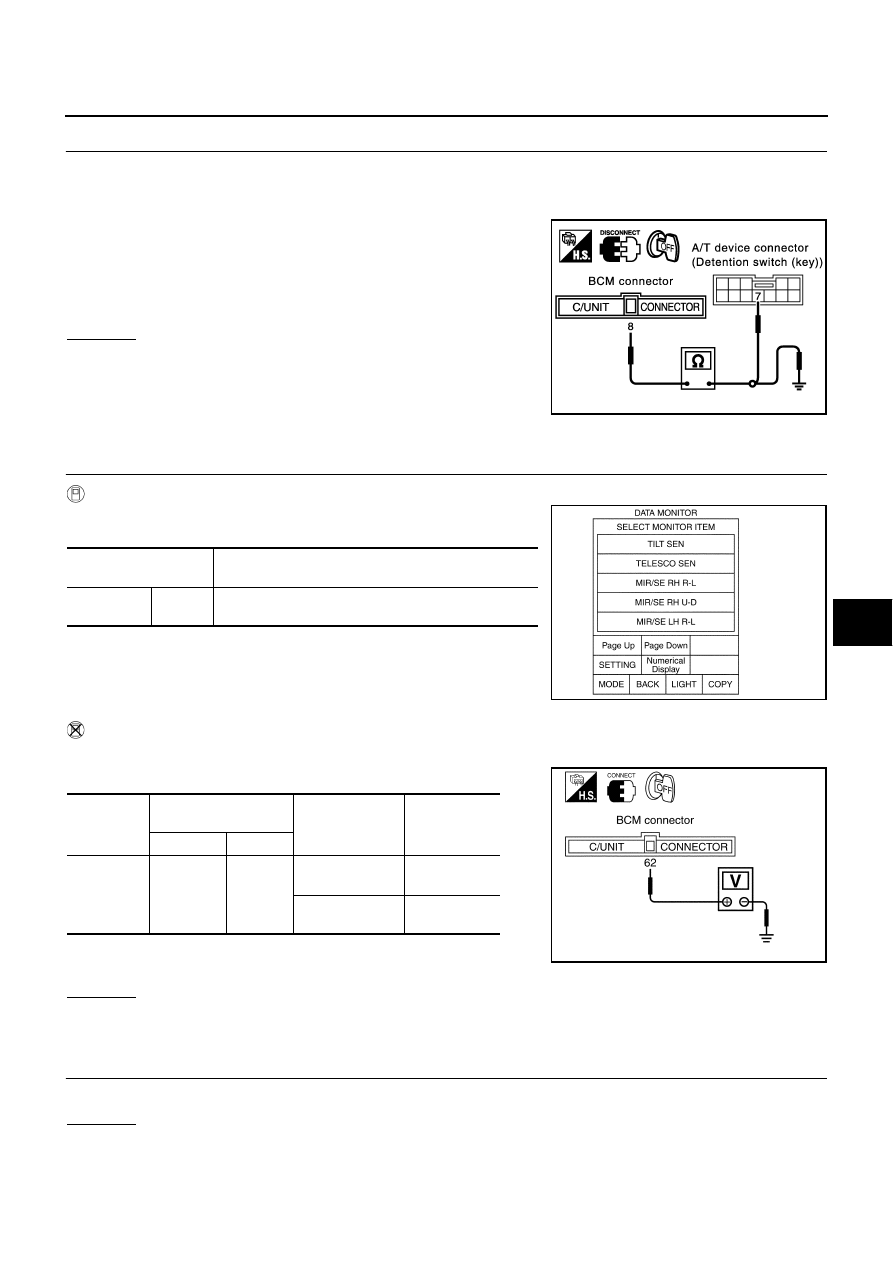

CHECK DETENTION SWITCH SIGNAL HARNESS

1.

Disconnect BCM connector.

2.

Check continuity between BCM connector M4 terminal 8 (G/OR) and A/T device (detention switch) con-

nector M97 terminal 7 (G/OR).

3.

Check continuity harness between BCM connector M4 terminal

8 (G/OR) and body ground.

OK or NG

OK

>> Replace BCM.

NG

>> Repair or replace harness between BCM and A/T device

(detention switch).

Telescopic Sensor Circuit Inspection

AIS001K7

1.

CHECK FUNCTION

With CONSULT-II

Operate the telescopic switch with “TELESCO SEN” on the DATA

MONITOR to check that the voltage changes.

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Check voltage between BCM connector and body ground.

OK or NG

OK

>> System is OK.

NG

>> GO TO 2.

2.

CHECK STEERING WHEEL TILT MECHANISM

Check the operation malfunction caused by steering wheel tilt mechanism deformation or parts are loose.

OK or NG

OK

>> GO TO 3.

NG

>> Repair the malfunctioning parts.

8 (G/OR) – 7(G/OR)

: Continuity should exist.

8 (G/OR) – Ground

: Continuity should not exist.

PIIA3283E

Monitor item [OPERA-

TION or UNIT]

Contents

TELESCO

SEN

"V"

The telescoping position (voltage) judged from the tele-

scoping sensor signal is displayed.

PIIA0295E

Connector

Terminals

(Wire color)

Condition

Voltage (V)

(Approx)

(+)

(–)

M4

62 (P/B)

Ground

Telescopic

top position

2

Telescopic

bottom position

4

PIIA0296E