Infiniti M45 (Y34). Manual - part 726

REAR FINAL DRIVE ASSEMBLY

RFD-17

C

E

F

G

H

I

J

K

L

M

A

B

RFD

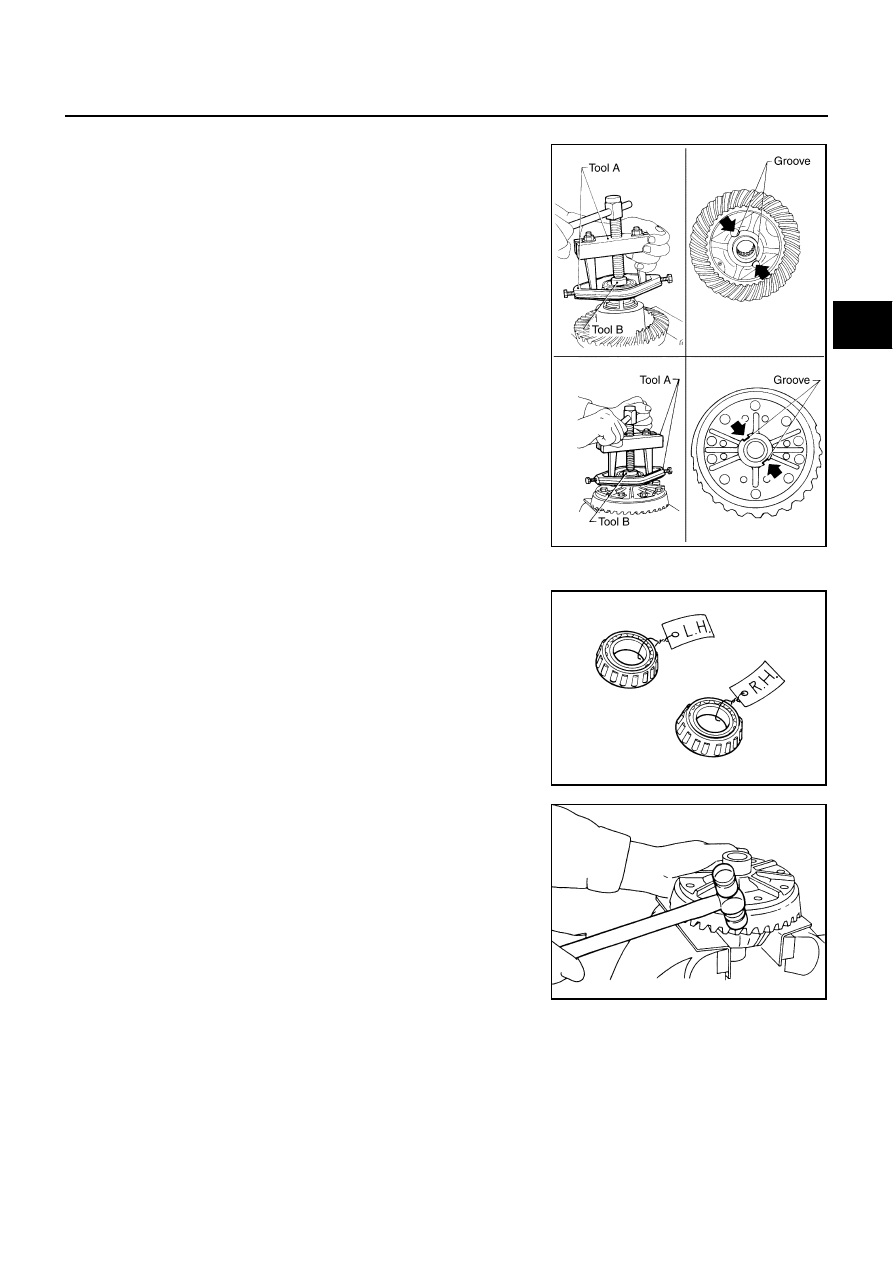

DISASSEMBLY OF DIFFERENTIAL CASE ASSEMBLY

1.

Remove side bearing inner race.

To prevent damage to bearing, engage puller jaws in groove.

CAUTION:

●

To prevent damage to the side bearing and drive gear,

place copper plates between these parts and vise.

●

It is not necessary to remove side bearing except it is

replaced.

●

Be careful not to confuse left- and right-hand parts.

Keep bearing and bearing race for each side together.

2.

Loosen drive gear bolts in a crisscross fashion.

3.

Tap drive gear off the differential case with a soft hammer.

●

Tap evenly all around to keep drive gear from binding.

Tool number

: A ST33051001 (J22888-20)

: B ST33061000 (J8107-2)

SPD920

SPD022

SPD024