Infiniti M45 (Y34). Manual - part 706

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

M

A

B

PS

INSTALLATION

In following items with care, install components in reverse order of

removal. Refer to

PS-13, "Removal and Installation"

●

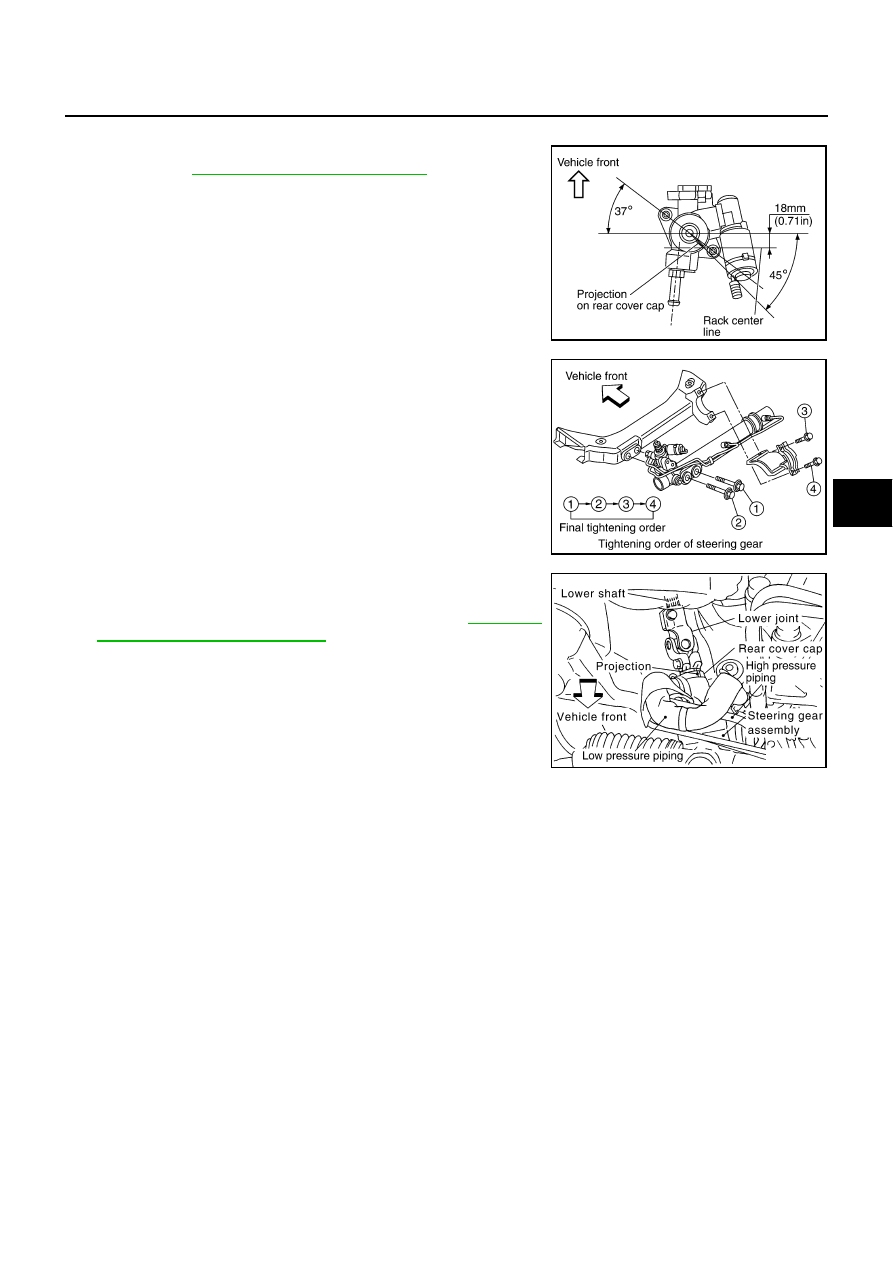

Confirm rear cover cap on steering gear consists with steering

gear when front wheels are set in straight ahead direction as

shown in figure.

●

Tighten steering gear assembly as shown in figure.

●

Confirm if slit of lower yoke of lower joint fits with projection on

rear cover cap.

●

After installation, bleed air from piping. Refer to

Bleeding from Hydraulic System"

.

INSPECTION AFTER INSTALLATION

●

Check if steering wheel turns smoothly when it is turned several times fully to end of left and right.

SGIA0402E

SGIA0404E

SGIA0392E