Infiniti M45 (Y34). Manual - part 533

CYLINDER HEAD

EM-69

C

D

E

F

G

H

I

J

K

L

M

A

EM

DISASSEMBLY

1.

Remove spark plug with the spark plug wrench (commercial service tool).

2.

Remove adjusting shim and valve lifter.

●

Confirm installation point and keep parts in an organized way to avoid mixing them up.

3.

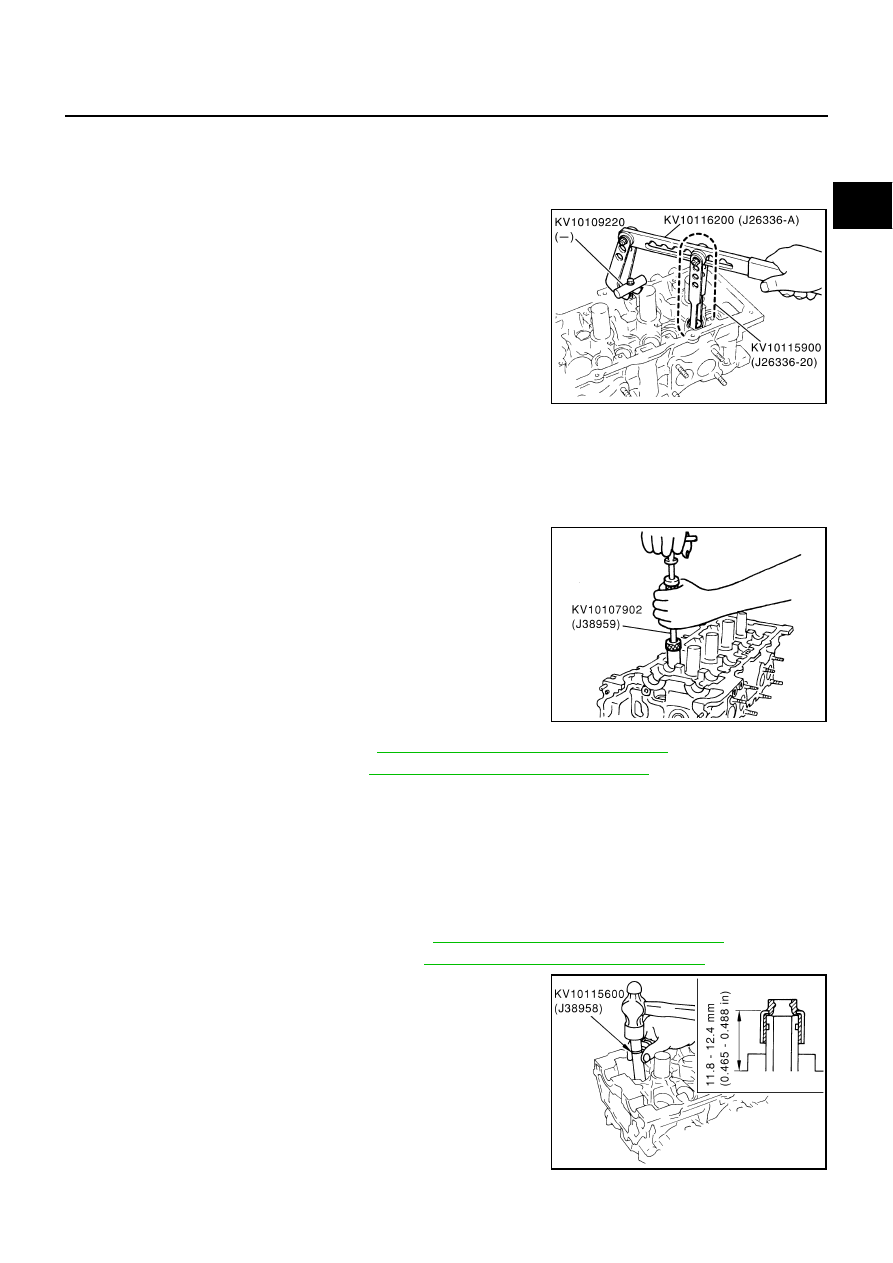

Remove valve collet.

●

Compress valve spring with the valve spring compressor,

attachment and adapter (SST). Remove valve collet with

magnetic hand.

CAUTION:

When working, take care not to damage valve lifter holes.

4.

Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION:

Do not remove valve spring seat from valve spring.

5.

Push valve stem to combustion chamber side, and remove valve.

●

Confirm installation point and keep parts in an organized way to avoid mixing then up.

6.

Remove valve oil seal with the valve oil seal puller (SST).

7.

If valve guide must be replaced, refer to

EM-71, "VALVE GUIDE REPLACEMENT"

8.

If valve seat must be replaced, refer to

EM-73, "VALVE SEAT REPLACEMENT"

9.

Remove spark plug tube, as necessary.

●

Using a pair of pliers, pull spark plug tube out of cylinder head.

CAUTION:

●

Take care not to damage cylinder head.

●

Once removed, a spark plug tube will be deformed and cannot be reused. Do not remove it

unless absolutely necessary.

ASSEMBLY

1.

When valve guide is removed, install it. Refer to

EM-71, "VALVE GUIDE REPLACEMENT"

.

2.

When valve seat is removed, install it. Refer to

EM-73, "VALVE SEAT REPLACEMENT"

3.

Install valve oil seal.

●

Install with the valve oil seal drift (SST) to match dimension in

illustration.

4.

Install valve.

●

Install larger diameter to intake side.

PBIC2360E

PBIC0072E

PBIC0073E