Infiniti M45 (Y34). Manual - part 532

CYLINDER HEAD

EM-65

C

D

E

F

G

H

I

J

K

L

M

A

EM

CYLINDER HEAD

PFP:11041

On-Vehicle Service

ABS000LW

CHECKING COMPRESSION PRESSURE

1.

Warm up engine thoroughly. Then, stop it.

2.

Remove engine cover (with power tool). Refer to

EM-12, "Removal and Installation"

3.

Release fuel pressure.

a.

Remove fuel pump fuse, and start engine. Refer to

EC-46, "FUEL PRESSURE RELEASE"

for fuel pump

fuse location.

b.

After engine stalls, crank it two or three times to release all fuel pressure.

●

Let fuel pump fuse removed until the end of step 7.

4.

Remove ignition coil and spark plug from each cylinder. Refer to

EM-28, "Removal and Installation"

and

EM-29, "Removal and Installation"

5.

Connect engine tachometer (not required in use of CONSULT-II).

6.

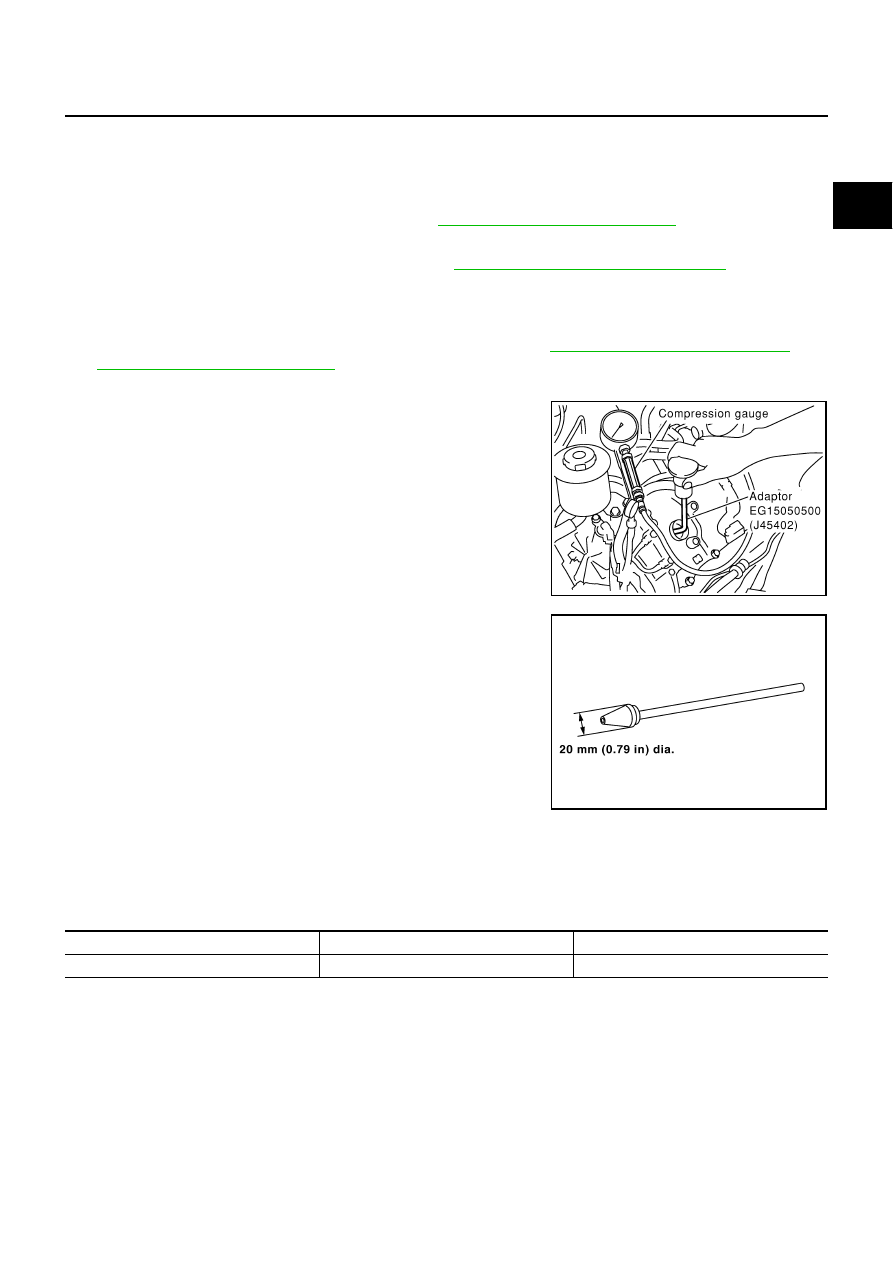

Install compression gauge with adapter (SST or commercial ser-

vice tool) onto spark plug hole.

●

Use compression gauge adapter (SST) which is required on

No. 7 and No. 8 cylinders.

●

Use the compression gauge adapter (if SST is not used)

which picking up end inserted to spark plug hole is smaller

than 20 mm (0.79 in) in diameter. Otherwise, it may be caught

by cylinder head during removal.

7.

With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge

pointer stabilizes, read the compression pressure and engine rpm. Perform these steps to check each cyl-

inder.

Compression pressure

Unit: kPa (kg/cm

2

, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

●

If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●

If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

●

If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug

hole of the cylinder to re-check it for compression.

PBIC1003E

SBIA0533E

Standard

Minimum

Difference limit between cylinders

1,320 (13.5, 191) / 300

1,130 (11.5, 164) / 300

98 (1.0, 14) / 300