Infiniti M45 (Y34). Manual - part 453

DTC P1147, P1167 HO2S2

EC-501

C

D

E

F

G

H

I

J

K

L

M

A

EC

3.

CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

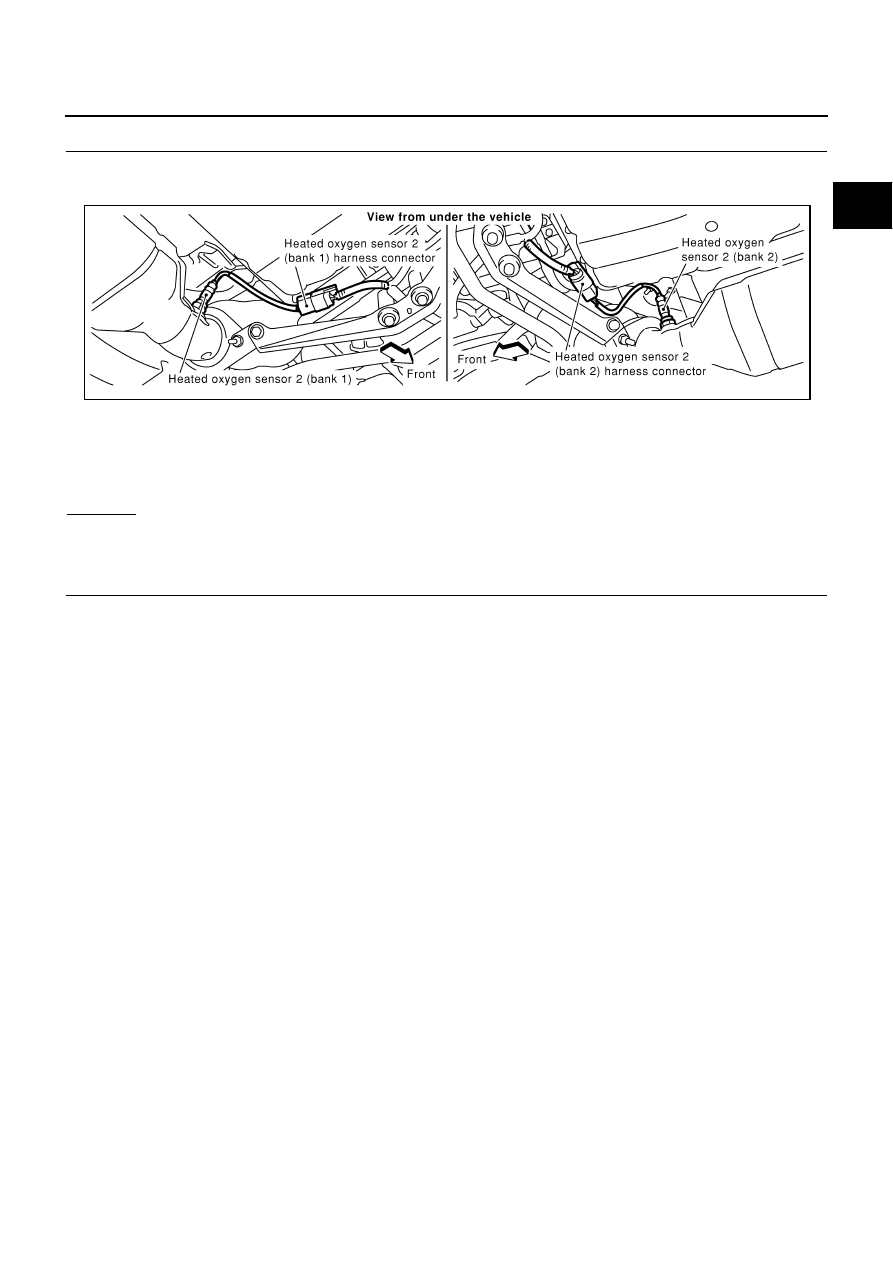

Disconnect heated oxygen sensor 2 harness connector.

3.

Check harness continuity between HO2S2 terminal 4 and ground.

Refer to Wiring Diagram.

4.

Also check harness for short to power.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors E315, F5

●

Joint connector-29

●

Harness open or short between HO2S2 and ground

>> Repair open circuit or short to power in harness or connectors.

Continuity should exist.

PBIB0018E