Infiniti M45 (Y34). Manual - part 409

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-325

C

D

E

F

G

H

I

J

K

L

M

A

EC

4.

CHECK IGNITION TIMING

Check the following items. Refer to

OK or NG

OK

>> GO TO 5.

NG

>> Follow the

5.

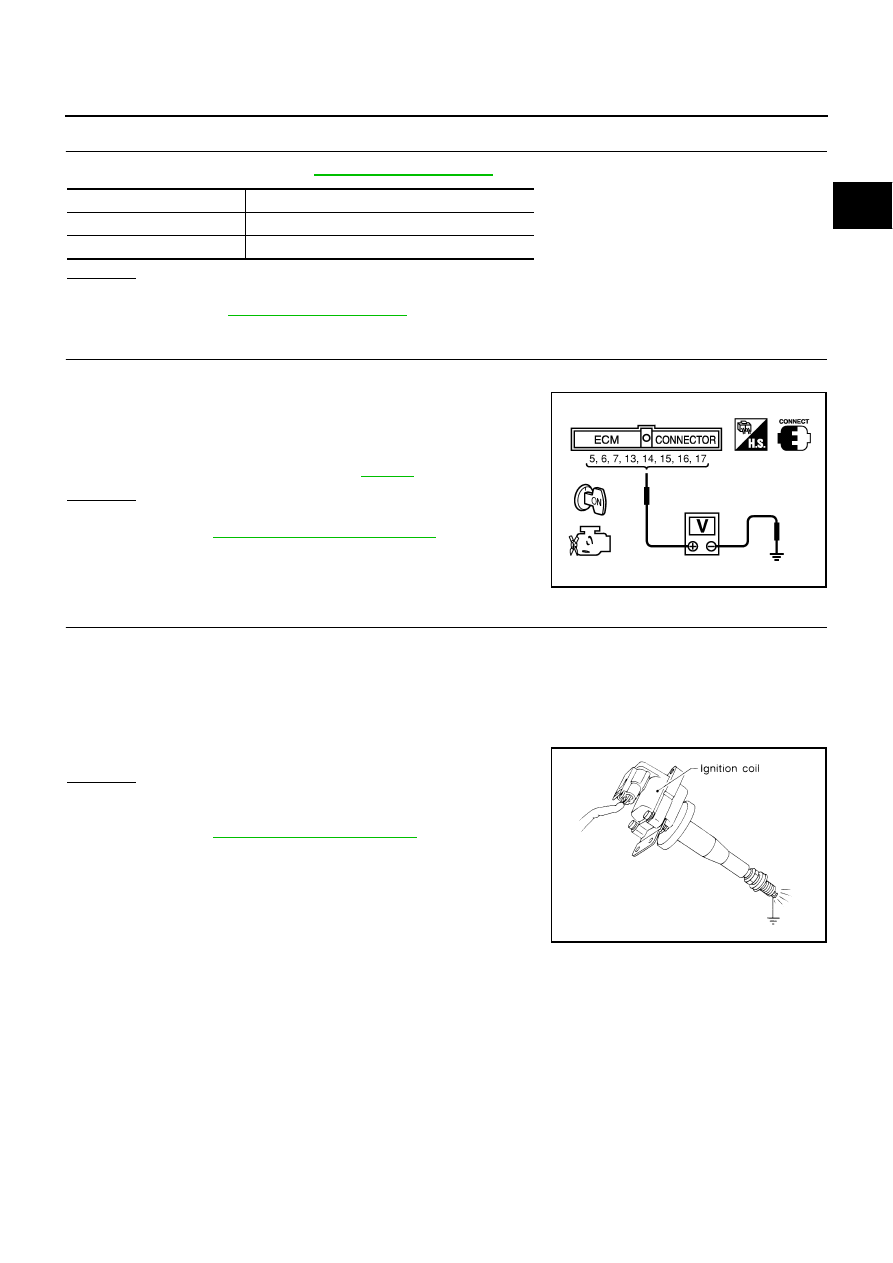

CHECK INJECTORS

1.

Stop engine and then turn ignition switch ON.

2.

Check voltage between ECM terminals 5, 6, 7, 13, 14, 15, 16, 17

and ground with CONSULT-II or tester.

3.

Refer to Wiring Diagram for Injectors,

OK or NG

OK

>> GO TO 6.

NG

>> Perform

EC-665, "Diagnostic Procedure"

6.

CHECK IGNITION SPARK

1.

Turn ignition switch OFF.

2.

Remove ignition coil assembly from rocker cover.

3.

Connect a known-good spark plug to the ignition coil assembly.

4.

Disconnect all injector harness connectors.

5.

Place end of spark plug against a suitable ground and crank engine.

6.

Check for spark.

OK or NG

OK

>> GO TO 7.

NG

>> Check ignition coil with power transistor and their circuit.

Refer to

.

Items

Specifications

Ignition timing

12

°

±

5

°

BTDC (in P or N position)

Target idle speed

650

±

50 rpm (in P or N position)

Voltage: Battery voltage

PBIB0069E

SEF575Q