Infiniti M45 (Y34). Manual - part 60

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

AT-125

D

E

F

G

H

I

J

K

L

M

A

B

AT

TCM terminal and data are reference value. Measured between each terminal and ground.

Diagnostic Procedure

ACS0047Q

1.

CHECK INPUT SIGNALS

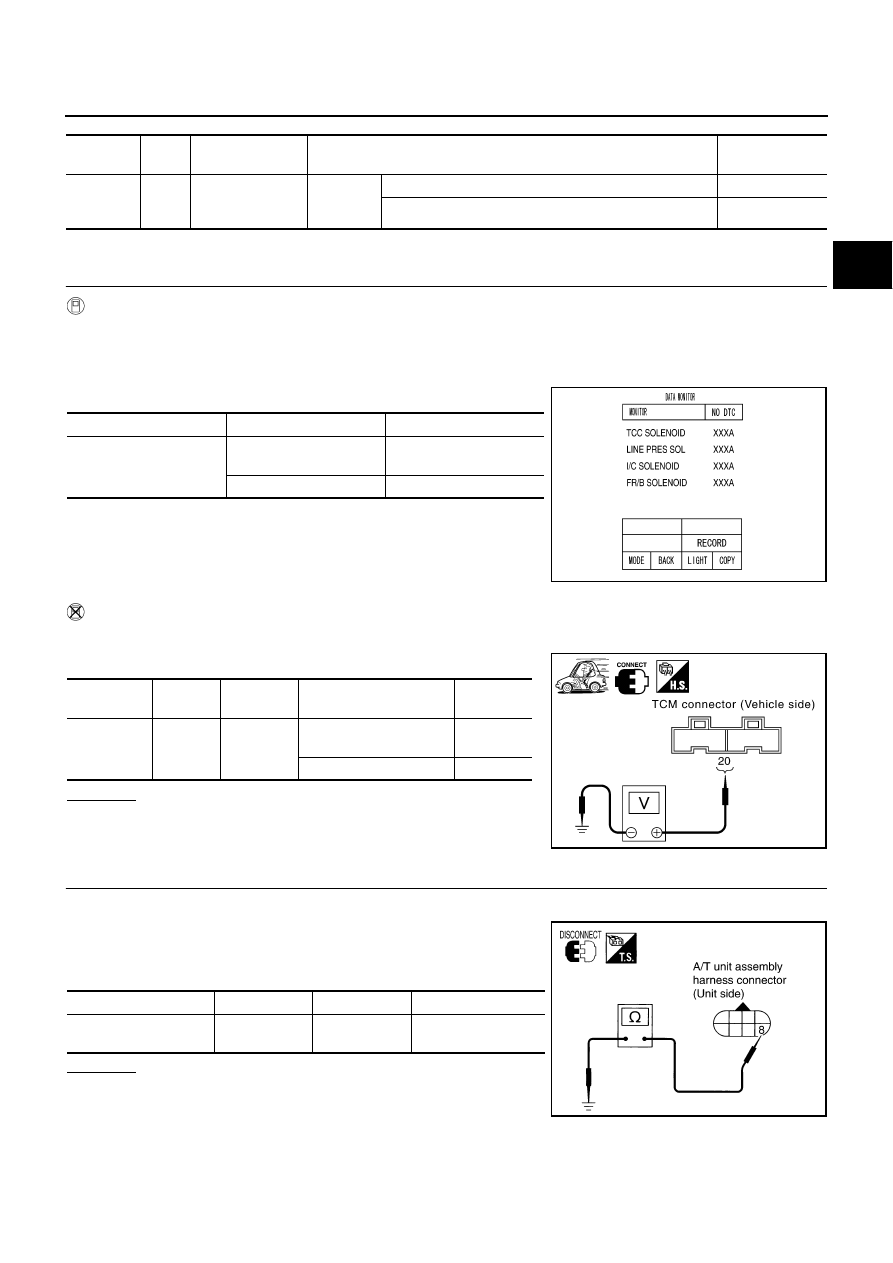

With CONSULT-II

1.

Start engine.

2.

Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

3.

Read out the value of “TCC SOLENOID” while driving.

Check the value changes according to driving speed.

Without CONSULT-II

1.

Start engine.

2.

Check voltage between TCM connector and ground.

OK or NG

OK >> GO

TO

6.

NG

>> GO TO 2.

2.

CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect A/T unit assembly harness connector at the trans-

mission right side.

3.

Check the resistance between terminal and ground.

OK or NG

OK >> GO

TO

5.

NG

>> GO TO 3.

Terminal

No.

Wire

color

Item

Condition

Data (Approx.)

20

Y

TCC solenoid

valve

When

vehicle

cruises

When lock-up

More than 2V

When not lock-up

0V

Item name

Condition

Display value (Approx.)

TCC SOLENOID

When perform slip lock-

up

0.2 - 0.4A

When perform lock-up

0.4 - 0.6A

SCIA4462E

Item

Connec-

tor No.

Terminal

No.

Condition

Data

(Approx.)

TCC sole-

noid valve

F103

20 (Y) -

Ground

When lock-up

More than

2V

When not lock-up

0V

SCIA4464E

Solenoid valve

Connector No.

Terminal No.

Resistance (Approx.)

Torque converter clutch

solenoid valve

F27

8 - Ground

3 - 9

Ω

SCIA1830E