Infiniti M35/M45 Y50. Manual - part 973

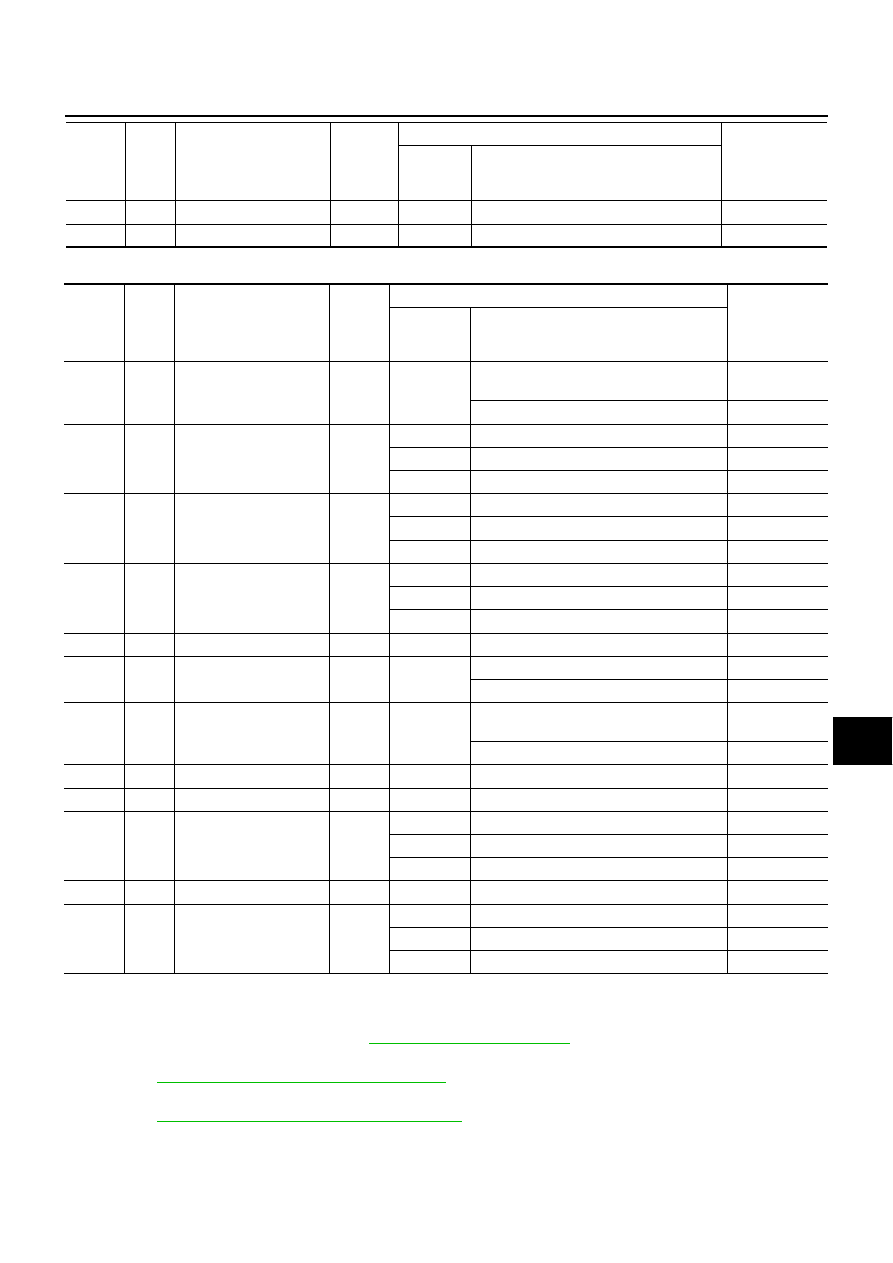

PDU (POWER DISTRIBUTION UNIT)

PG-37

C

D

E

F

G

H

I

J

L

M

A

B

PG

Terminals and Reference Value for PDU

NKS004EH

Work Flow

NKS004EI

1.

Check the symptom and customer's requests.

2.

Understand outline of system. Refer to

3.

Confirm that Intelligent Key system operates normally.

Refer to

BL-24, "POWER DOOR LOCK SYSTEM"

.

4.

Repair or replace any malfunctioning parts.

Refer to

PG-38, "Trouble Diagnosis Symptom Chart"

.

5.

INSPECTION END

57

L

Power source (Fuse)

Input

LOCK

—

Battery voltage

72

B

Ground

—

—

—

0

Termi-

nal

Wire

Color

Item

Signal

Input/

Output

Condition

Voltage (V)

Approx.

Ignition

Switch

Position

Operation or Conditions

Termi-

nal

Wire

Color

Item

Signal

Input/

Output

Condition

Voltage (V)

Approx.

Ignition

Switch

Position

Operation or Conditions

1

P

PDU wake up signal

Output

LOCK

Push-button ignition switch is in LOCK

state, 30 seconds after all doors close

Battery voltage

Other than above

0

4

BR

Ignition signal 1

Output

LOCK

—

Battery voltage

ACC

—

Battery voltage

ON

—

0

5

W

Ignition signal 2

Output

LOCK

—

Battery voltage

ACC

—

Battery voltage

ON

—

0

8

SB

ACC signal

Output

LOCK

—

Battery voltage

ACC

—

0

ON

—

0

10

B

Ground

—

—

—

0

11

Y

IPDM E/R status signal

Input

—

Engine starting (During Cranking)

5

Other than above

2

12

R

PDU feedback signal

Input

LOCK

Push-button ignition switch is in LOCK

state, 30 seconds after all doors close

1

Other than above

0

14

SB

Power source (Fuse)

Input

LOCK

—

Battery voltage

15

L

Power source (F/L)

Input

LOCK

—

Battery voltage

16

W

ACC power output

Output

LOCK

—

0

ACC

—

Battery voltage

ON

—

Battery voltage

17

G

Power source (Fuse)

Input

LOCK

—

Battery voltage

18

BR

ON power output

Output

LOCK

—

0

ACC

—

0

ON

—

Battery voltage