Infiniti M35/M45 Y50. Manual - part 956

ENGINE MAINTENANCE (VQ35DE ENGINE)

MA-21

C

D

E

F

G

H

I

J

K

M

A

B

MA

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling occurs with the standard type spark plug under conditions

such as:

●

Frequent engine starts

●

Low ambient temperatures

The cold type spark plug is suitable when spark knock occurs with the standard type spark plug under condi-

tions such as:

●

Extended highway driving

●

Frequent high engine revolution

CAUTION:

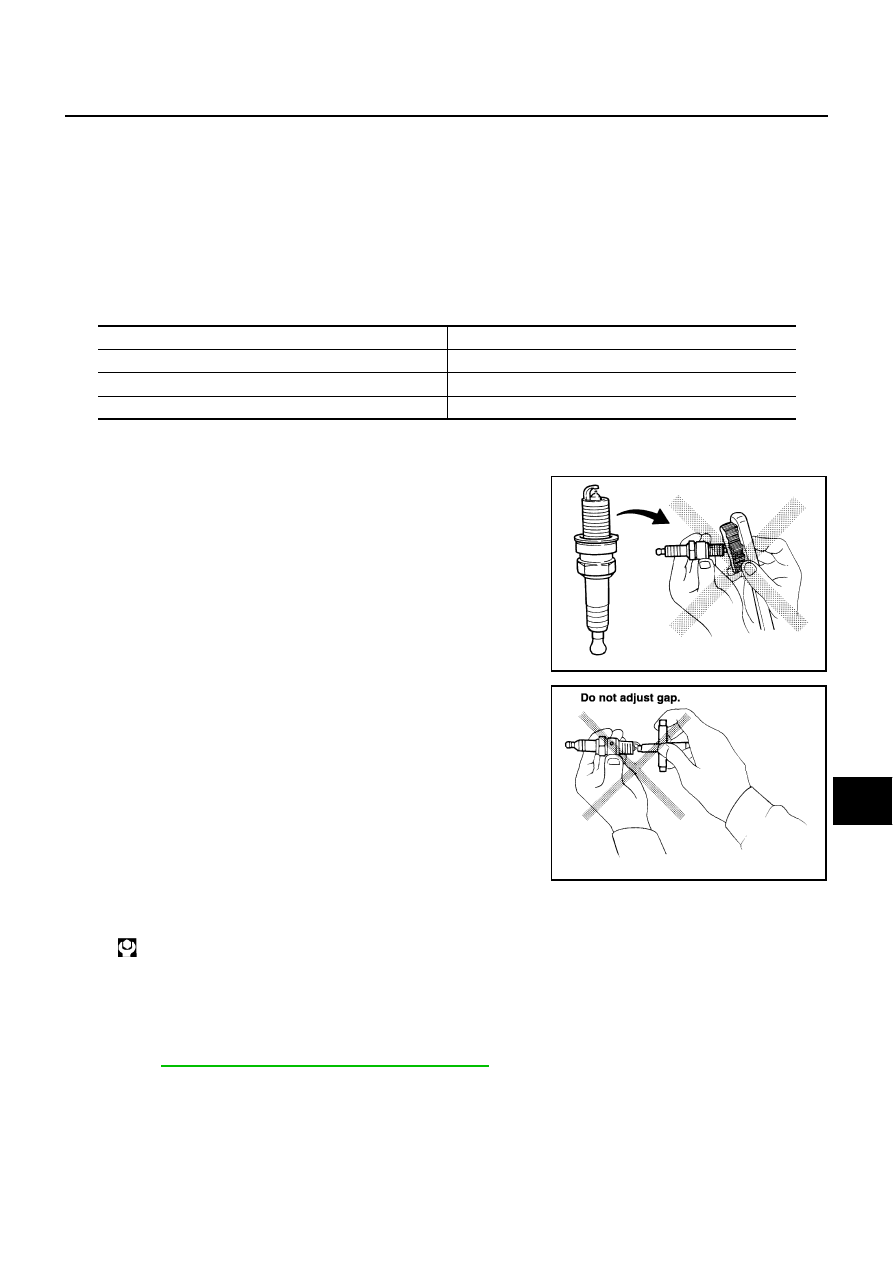

●

Do not drop or shock spark plug.

●

Do not use a wire brush for cleaning.

●

If plug tip is covered with carbon, spark plug cleaner may

be used.

●

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor Lines

NLS0007P

1.

Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2.

Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to

EC-39, "EVAPORATIVE EMISSION SYSTEM"

.

Make

NGK

Standard type

PLFR5A-11

Hot type

PLFR4A-11

Cold type

PLFR6A-11

Gap (Nominal)

: 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2

, 85 psi)

Cleaning time:

Less than 20 seconds

SMA773C

SMA806CA

: 24.5 N·m (2.5 kg-m, 18 ft-lb)