Infiniti M35/M45 Y50. Manual - part 901

ACTIVE AFS

LT-149

C

D

E

F

G

H

I

J

L

M

A

B

LT

Terminals and Reference Values for AFS Control Unit

NKS003QJ

Ter-

minal

No.

Wire

color

Item

Measuring condition

Reference value

Ignition

switch

Operation or condition

1

B/R

IGN power supply

ON

—

Battery voltage

2

W/R

Swivel position sensor ground

(right)

ON

—

Approx. 0 V

3

GR

AFS switch signal

ON

AFS switch

ON

Approx. 0 V

OFF

Battery voltage

4

Y

Swivel position sensor power

supply (right)

ON

—

Approx. 5 V

6

V/W

Height sensor power supply

ON

—

Approx. 5 V

7

P

CAN-L

—

—

—

8

B/R

Height sensor ground

ON

—

Approx. 0 V

9

W/B

Swivel position sensor signal

(right)

ON

Low beam headlamp

(right) swivel angle

0

°

Approx. 1.5 V

Maximum

angle

Approx. 2.5 V

11

R

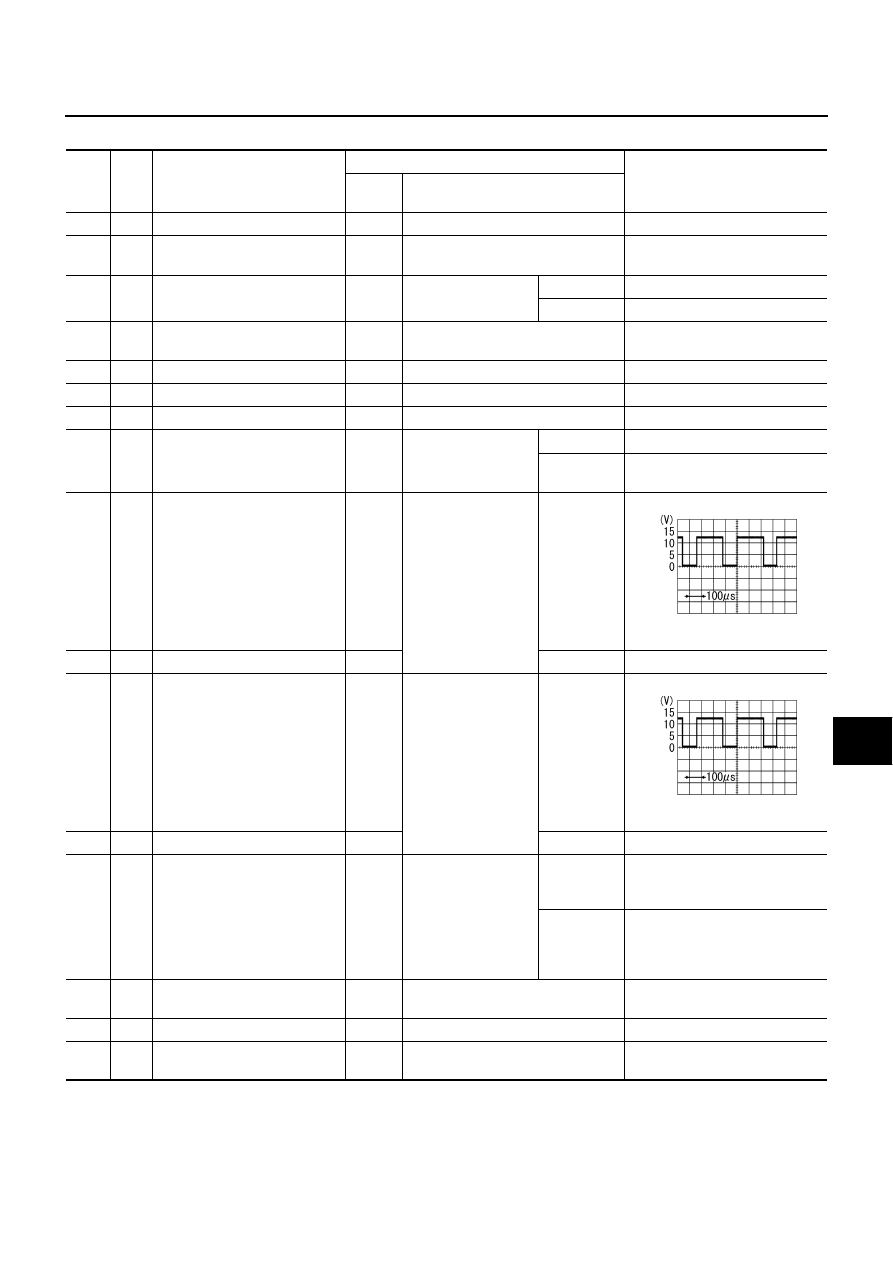

Swivel motor 1 phase

−

(right)

ON

Low beam headlamp

(right) swivel

ON

Reference waveform

Approx. 8 - 12 V

13

B

Swivel motor 2 phase

−

(right)

ON

OFF

Approx. 9.5 - 11.5 V

15

BR/L

Swivel motor 1 phase+ (left)

ON

Low beam headlamp

(left) swivel

ON

Reference waveform

Approx. 8 - 12 V

17

Y/G

Swivel motor 2 phase+ (left)

ON

OFF

Approx. 9.5 - 11.5 V

19

V

Aiming motor drive signal (right)

ON

Low beam headlamp

(right) auto aiming

Unloaded

vehicle posi-

tion

Approx. 9 V

Maximum

laden condi-

tion

Approx. 4.8 V

(With 18- inch wheel)

Approx. 5.2 V

(With 19 -inch wheel)

24

V/R

Swivel position sensor power

supply (left)

ON

—

Approx. 5 V

25

B

Ground

ON

—

Approx. 0 V

27

R/W

Swivel position sensor ground

(left)

ON

—

Approx. 0 V

SKIB2408J

SKIB2408J