Infiniti M35/M45 Y50. Manual - part 777

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

FSU-5

[2WD]

C

D

F

G

H

I

J

K

L

M

A

B

FSU

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

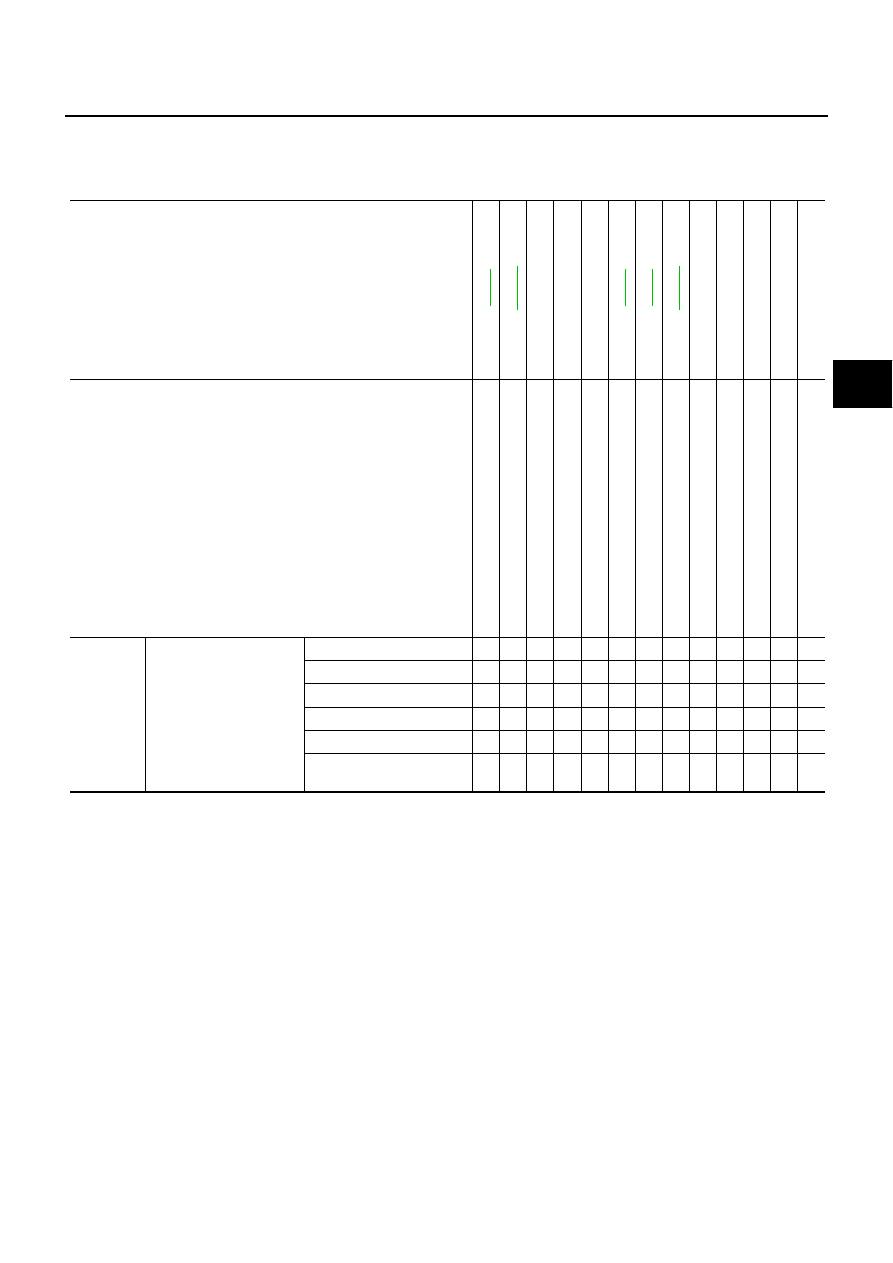

NVH Troubleshooting Chart

NES000I9

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

—

—

—

NVH

in

PR s

e

c

tio

n

NVH

in

F

A

X

a

n

d

FSU s

e

c

ti

o

n

NVH i

n

W

T

s

e

c

tio

n

NVH

in

BR s

e

c

tio

n

NVH

in

PS s

e

c

tio

n

Possible cause and SUSPECTED PARTS

Im

pr

o

per

i

n

st

al

la

ti

on

,

lo

osen

ess

S

tr

u

t d

e

fo

rm

at

ion,

d

a

m

age

or

d

e

fl

ec

ti

on

Bus

h

ing or

m

oun

ti

ng det

er

io

ra

ti

on

P

a

rt

s

in

te

rf

e

re

n

c

e

Spr

ing f

a

ti

gue

Sus

pens

io

n l

o

o

s

ene

ss

In

co

rr

ect

w

h

e

e

l al

ignm

en

t

S

ta

b

ili

z

er

bar

f

a

ti

g

u

e

PROPELL

E

R SHAF

T

FRONT AXLE AND FRO

N

T

SUSPENSION

ROAD W

H

EEL

BRAKES

STEERING

Symptom

FRONT SUSPENSION

Noise

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

×

Poor quality ride or han-

dling

×

×

×

×

×

×

×

×

×