Infiniti M35/M45 Y50. Manual - part 773

FUEL SYSTEM

FL-3

C

D

E

F

G

H

I

J

K

L

M

A

FL

FUEL SYSTEM

PFP:17503

Checking Fuel Lines

NBS005R8

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General Precautions

NBS005R9

WARNING:

When replacing fuel line parts, be sure to observe the following.

●

Put a “CAUTION: FLAMMABLE” sign in the workshop.

●

Be sure to work in a well ventilated area and furnish workshop with a CO

2

fire

extinguisher.

●

Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

●

Use gasoline required by the regulations for octane number. Refer to

(Unleaded Premium Gasoline Required) (VK45DE Engine Models)"

.

●

Before removing fuel line parts, perform out the following procedures:

–

Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

–

Release fuel pressure from the fuel lines. Refer to

EC-88, "FUEL PRESSURE RELEASE"

EC-790, "FUEL PRESSURE RELEASE"

–

Disconnect the battery cable from the negative terminal.

●

Always replace O-ring and clamps with new ones.

●

Do not kink or twist tubes when they are being installed.

●

Do not tighten hose clamps excessively to avoid damaging hoses.

●

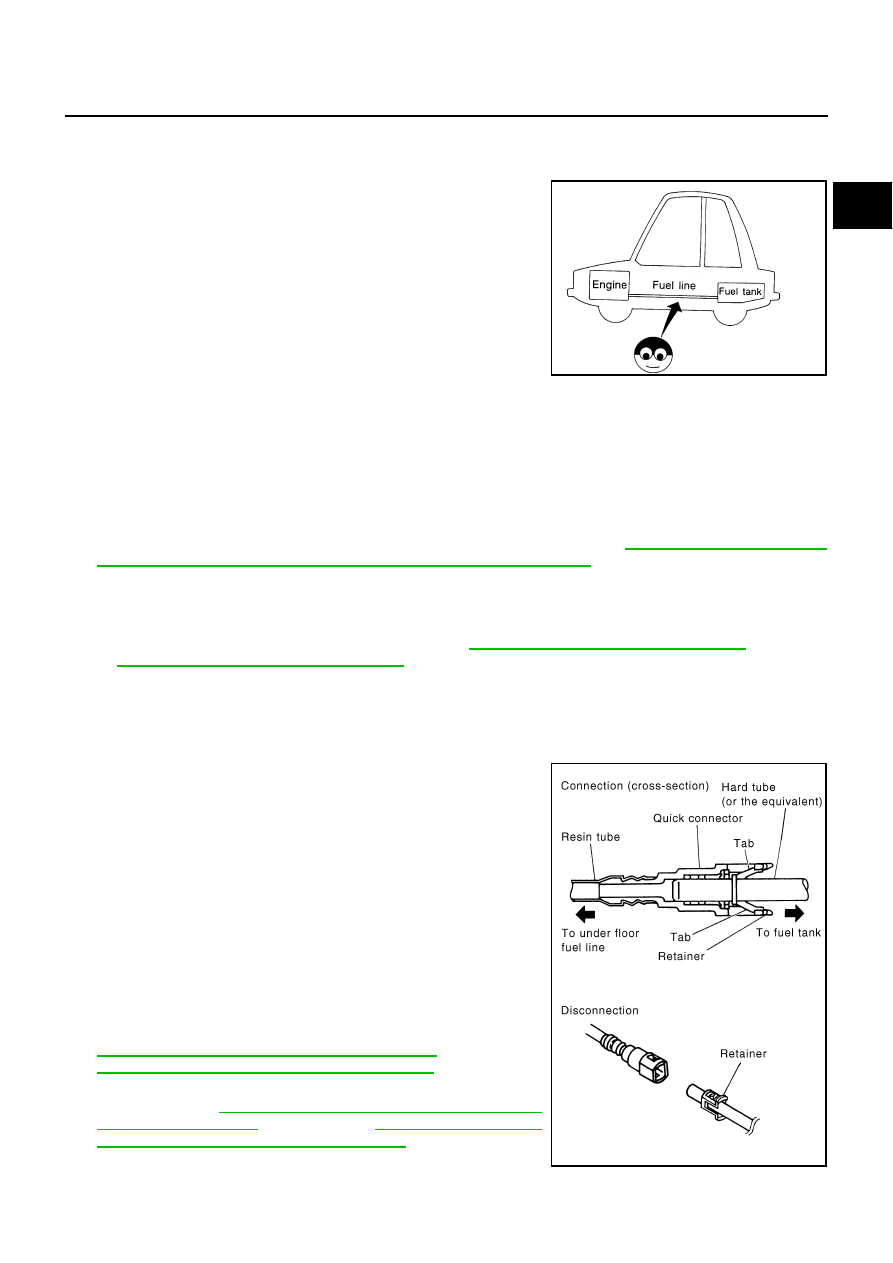

After connecting fuel tube quick connectors, make sure

quick connectors are secure.

Ensure that connector and resin tube do not contact any

adjacent parts.

●

After installing tubes, make sure there is no fuel leakage at

connections in the following steps.

–

Apply fuel pressure to fuel lines with turning ignition switch

“ON” (with engine stopped). Then check for fuel leaks at

connections.

–

Start engine and rev it up and check for fuel leaks at con-

nections.

●

Use only a genuine NISSAN fuel filler cap as a replacement.

If an incorrect fuel filler cap is used, the “MIL” may come

on.

●

For servicing “Evaporative Emission System” parts, refer to

EC-39, "EVAPORATIVE EMISSION SYSTEM"

(VQ35DE) or

EC-741, "EVAPORATIVE EMISSION SYSTEM"

(VK45DE).

●

For servicing“On Board Refueling Vapor Recovery (ORVR)”

parts, refer to

EC-46, "ON BOARD REFUELING VAPOR

REFUELING VAPOR RECOVERY (ORVR)"

(VK45DE).

SMA803A

SBIA0504E