Infiniti M35/M45 Y50. Manual - part 760

FRONT WHEEL HUB AND KNUCKLE

FAX-5

C

E

F

G

H

I

J

K

L

M

A

B

FAX

FRONT WHEEL HUB AND KNUCKLE

PFP:40202

On-Vehicle Inspection

NDS000FF

Make sure that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

●

Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

●

Rotate wheel hub and make sure that is no unusual noise or other irregular conditions. If there is any of

irregular conditions, replace wheel hub and bearing assembly

Removal and Installation

NDS000FG

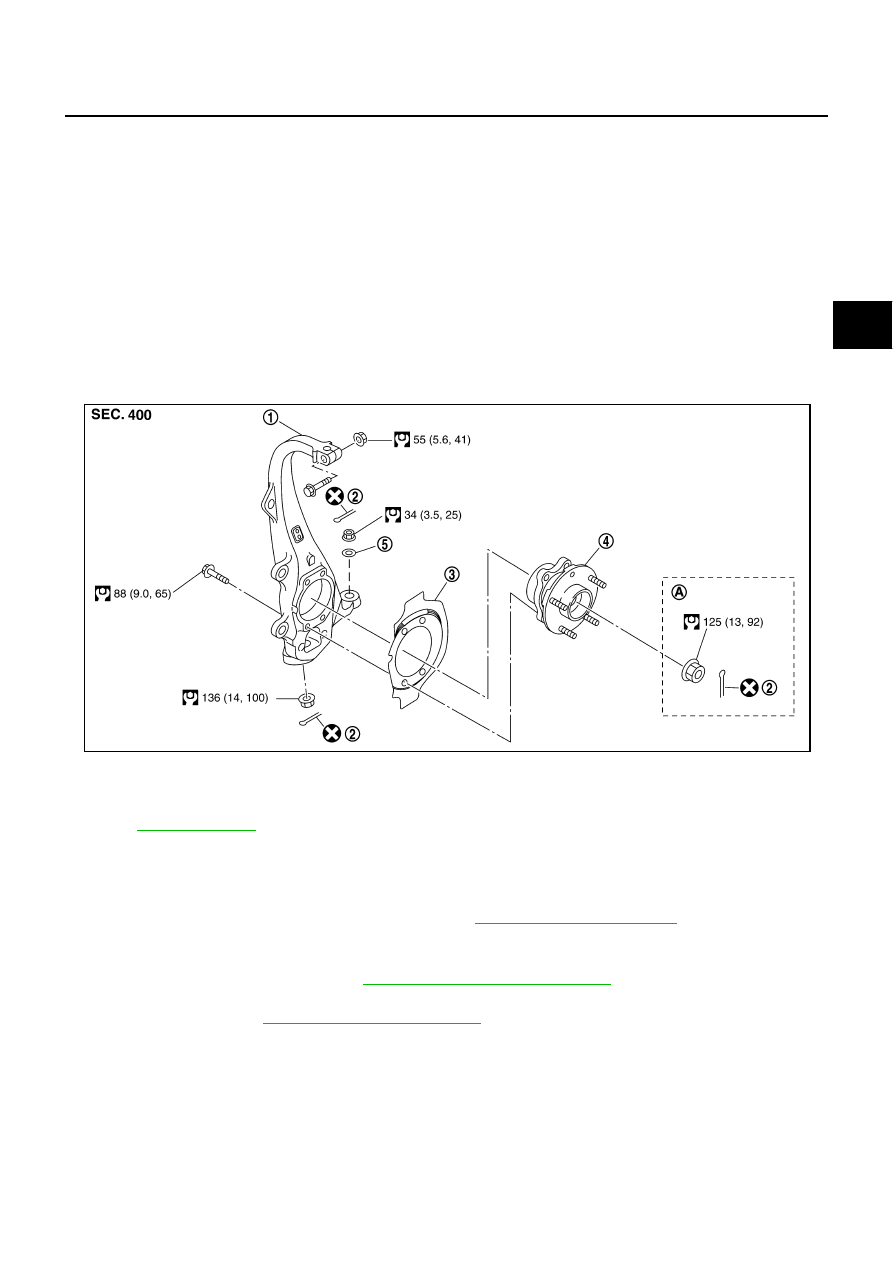

COMPONENT

REMOVAL

Wheel Hub and Bearing Assembly

1.

Remove tires from vehicle with power tool.

2.

Remove wheel sensor from steering knuckle. Refer to

.

CAUTION:

Do not pull on wheel sensor harness.

3.

Remove brake hose bracket. Refer to

4.

Remove torque member fixing bolts with power tool. Hang torque member in a place where it will not inter-

fere with work. Refer to

CAUTION:

Do not depress brake pedal while brake caliper is removed.

Axial end play

: 0.05 mm (0.002 in) or less

1.

Steering knuckle

2.

Cotter pin

3.

Splash guard

4.

Wheel hub and bearing assembly

5.

Washer

A: AWD

models

Refer to

, for the symbols in the figure.

SDIA3256E