Infiniti M35/M45 Y50. Manual - part 672

DTC P0456 EVAP CONTROL SYSTEM

EC-1161

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

CAUTION:

●

Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used,

the MIL may come on.

●

If the fuel filler cap is not tightened properly, the MIL may come on.

●

Use only a genuine NISSAN rubber tube as a replacement.

DTC Confirmation Procedure

NBS005IM

NOTE:

●

If DTC P0456 is displayed with P0442, first perform trouble diagnosis for DTC P0456.

●

After repair, make sure that the hoses and clips are installed properly.

●

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait

at least 10 seconds before conducting the next test.

TESTING CONDITION:

●

Open engine hood before conducting following procedure.

●

If any of following conditions are met just before the DTC confirmation procedure, leave the vehi-

cle for more than 1 hour.

–

Fuel filler cap is removed.

–

Fuel is refilled or drained.

–

EVAP component parts is/are removed.

●

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

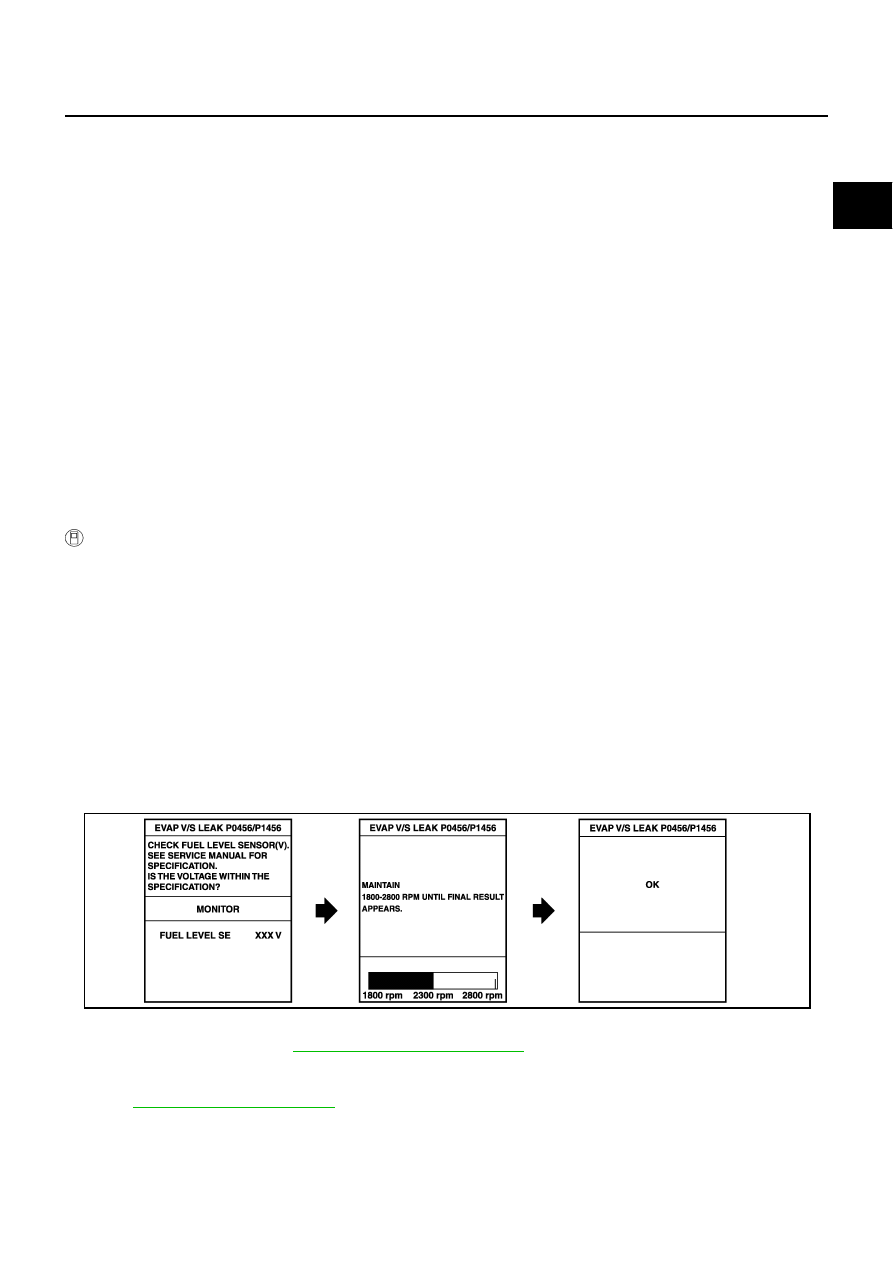

WITH CONSULT-II

1.

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-II.

2.

Make sure the following conditions are met.

FUEL LEVEL SE: 0.25 - 1.4V

COOLAN TEMP/S: 0 - 32

°

C (32 - 90

°

F)

FUEL T/TMP SE: 0 - 35

°

C (32 - 95

°

F)

INT/A TEMP SE: More than 0

°

C (32

°

F)

If NG, turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle) or refilling/draining

fuel until the output voltage condition of the “FUEL LEVEL SE” meets within the range above and leave

the vehicle for more than 1 hour. Then start from step 1).

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Turn ignition switch ON.

5.

Select “EVAP V/S LEAK P0456/P1456” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode

with CONSULT-II.

Follow the instruction displayed.

6.

Make sure that “OK” is displayed.

If “NG” is displayed, refer to

EC-1163, "Diagnostic Procedure"

.

NOTE:

●

If the engine speed cannot be maintained within the range displayed on CONSULT-II screen, go

to

●

Make sure that EVAP hoses are connected to EVAP canister purge volume control solenoid

valve properly.

PBIB0837E