Infiniti M35/M45 Y50. Manual - part 578

BASIC SERVICE PROCEDURE

EC-785

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

17.

DETECT MALFUNCTIONING PART

Check the following.

●

Check camshaft position sensor (PHASE) and circuit. Refer to

EC-1082, "DTC P0340 CAMSHAFT POSI-

●

Check crankshaft position sensor (POS) and circuit. Refer to

EC-1075, "DTC P0335 CKP SENSOR

OK or NG

OK

>> GO TO 18.

NG

>> 1. Repair or replace.

2. GO TO 4.

18.

CHECK ECM FUNCTION

1.

Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2.

Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-248, "ECM Re-Communicating Function"

>> GO TO 4.

19.

INSPECTION END

Did you replace ECM, referring this Basic Inspection procedure?

Yes or No

Yes

>> 1. Perform

.

2. INSPECTION END

No

>> INSPECTION END

Idle Speed and Ignition Timing Check

NBS005A7

IDLE SPEED

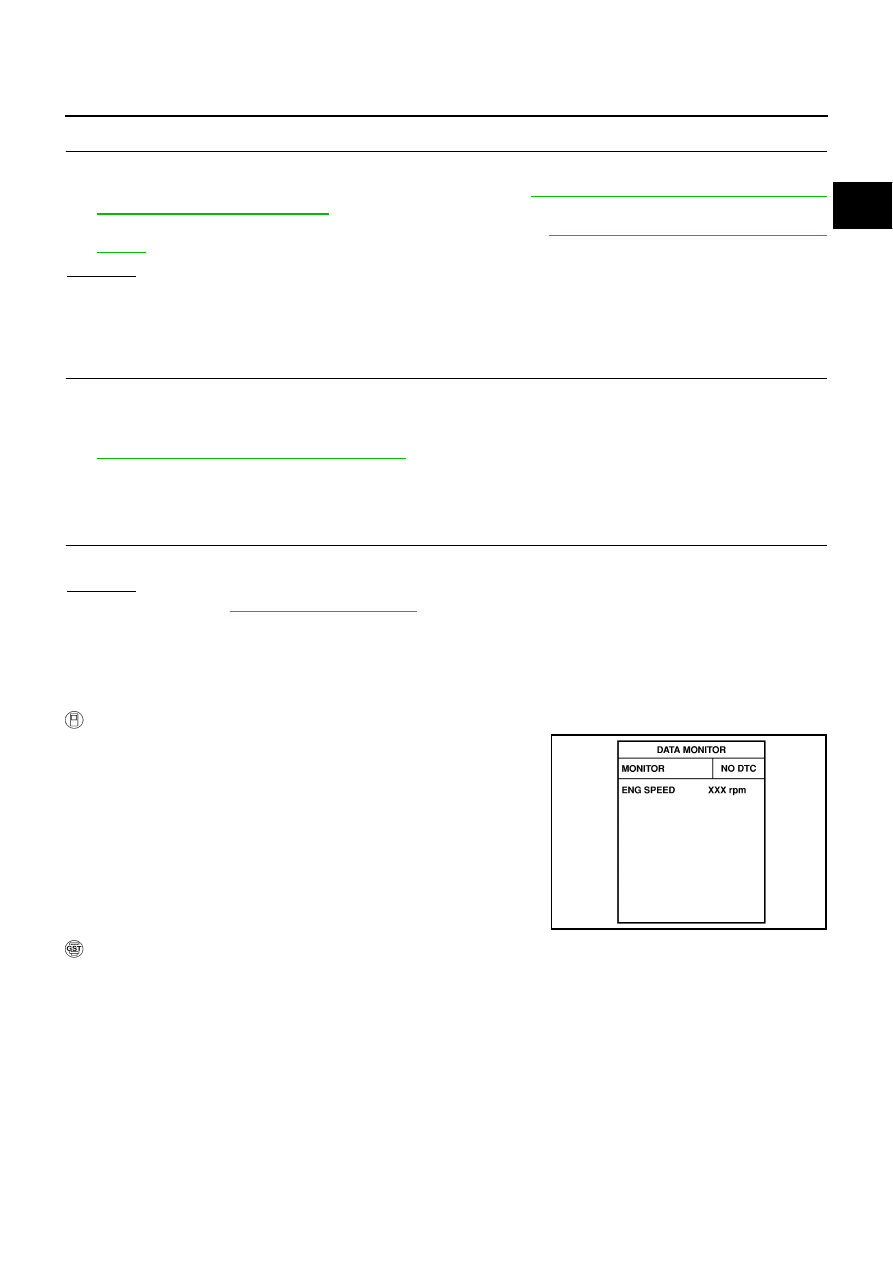

With CONSULT-II

Check idle speed in “DATA MONITOR” mode with CONSULT-II.

With GST

Check idle speed with GST.

IGNITION TIMING

Any of following two methods may be used.

SEF058Y