Infiniti M35/M45 Y50. Manual - part 569

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-749

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Diagnostic Procedure

NBS0059W

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG.

1.

CHECK EVAP CANISTER

1.

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2.

Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 2.0 kg (4.4 lb).

OK or NG

OK

>> GO TO 2.

NG

>> GO TO 3.

2.

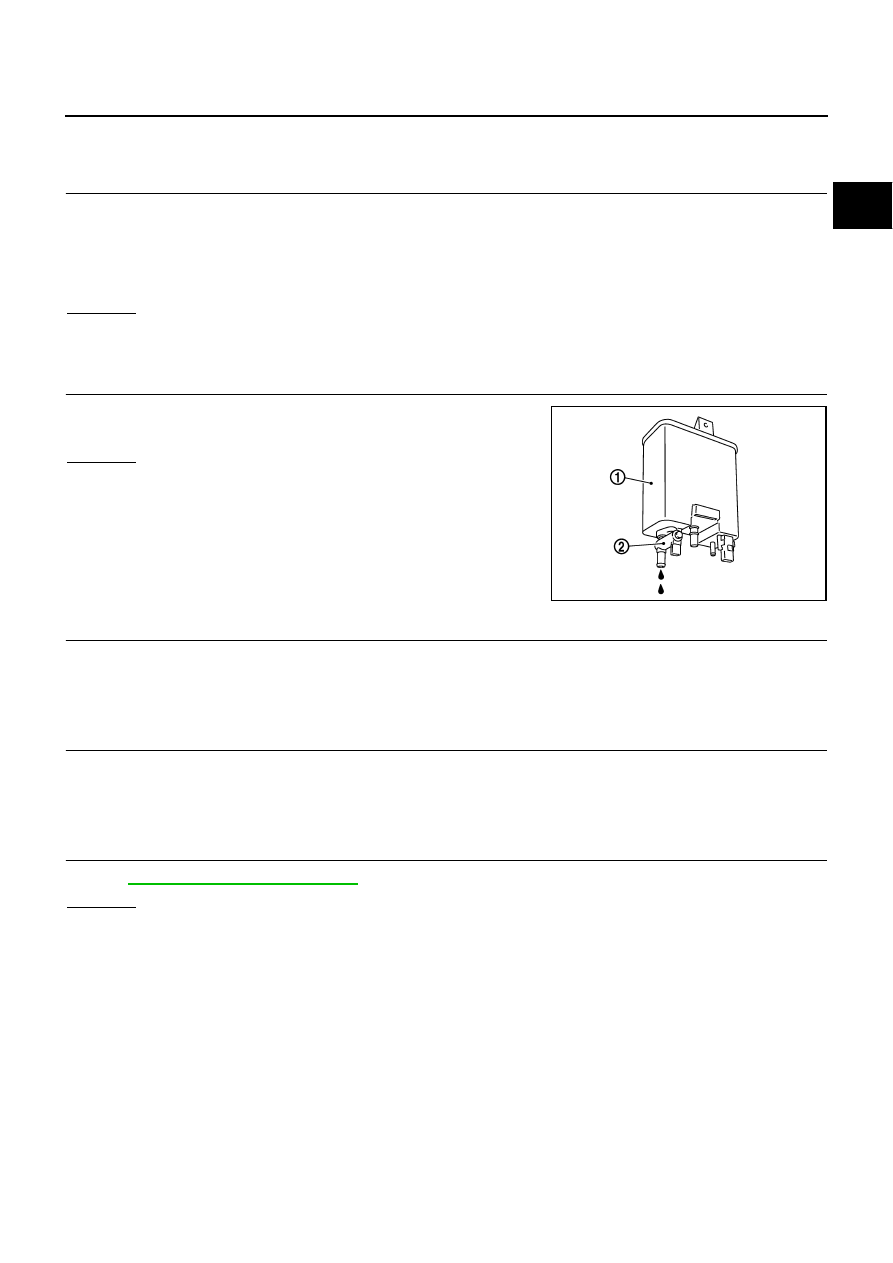

CHECK IF EVAP CANISTER SATURATED WITH WATER

Does water drain from the EVAP canister (1)?

●

EVAP canister vent control valve (2)

Yes or No

Yes

>> GO TO 3.

No

>> GO TO 5.

3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose.

5.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to

EC-751, "Component Inspection"

OK or NG

OK

>> INSPECTION END

NG

>> Replace refueling EVAP vapor cut valve with fuel tank.

PBIB2731E