Infiniti M35/M45 Y50. Manual - part 533

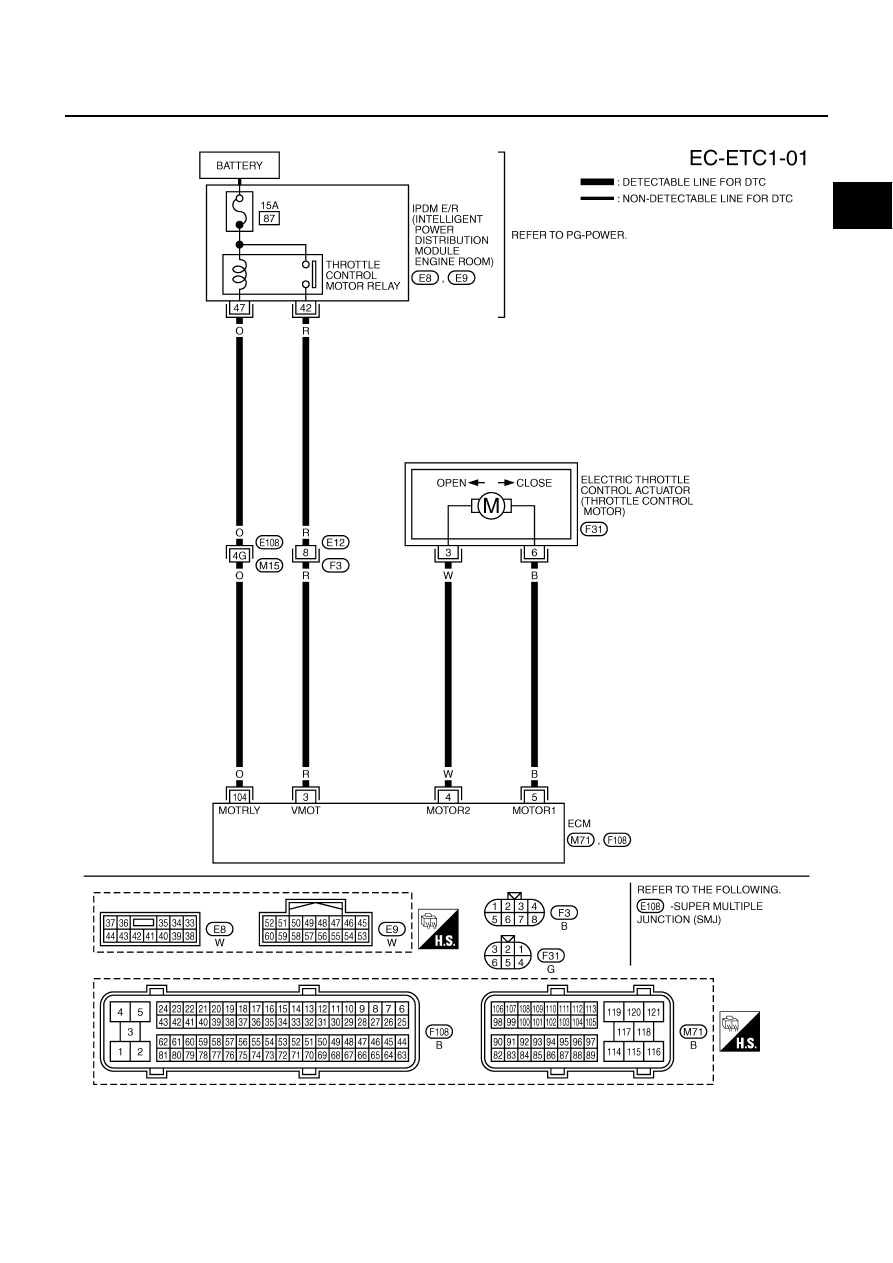

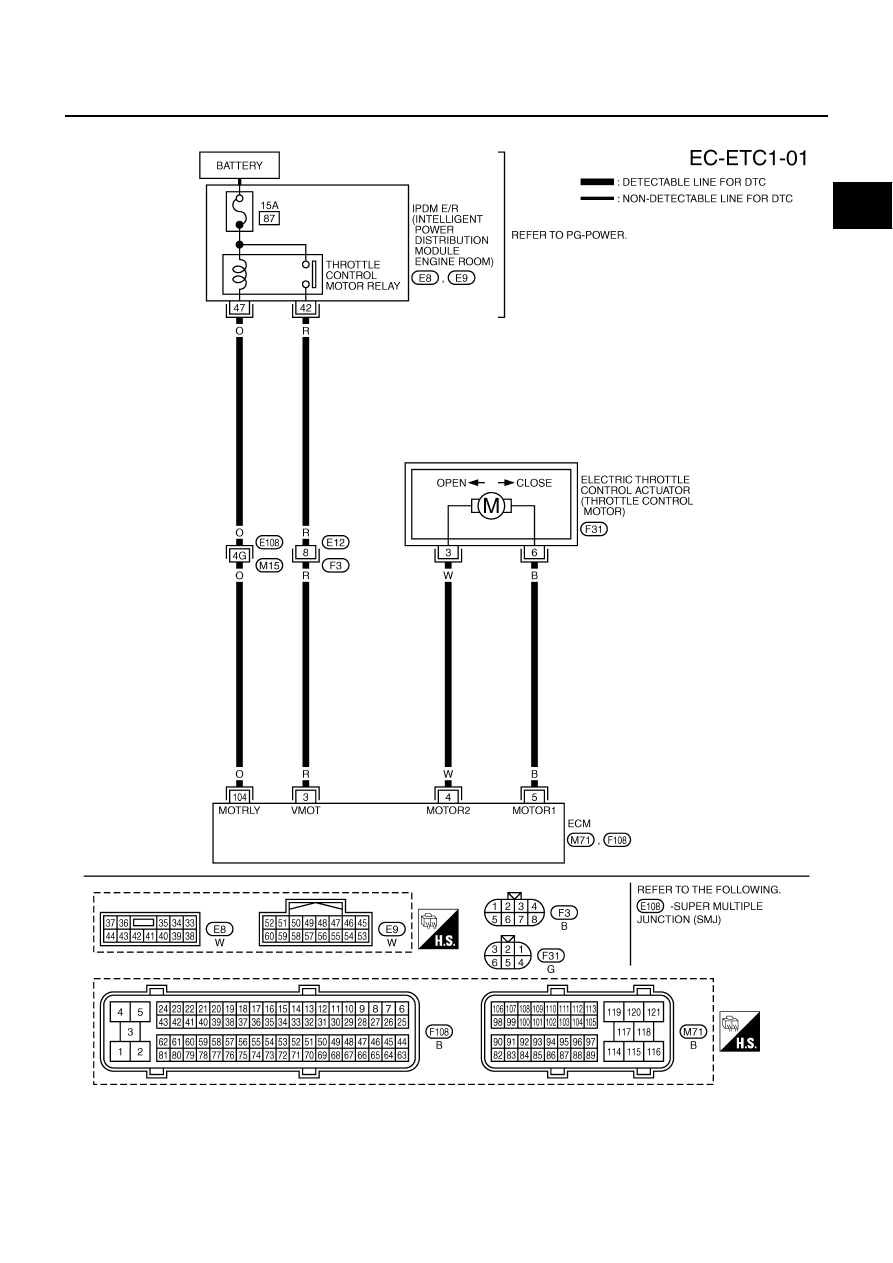

DTC P2101 ELECTRIC THROTTLE CONTROL FUNCTION

EC-605

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Wiring Diagram

NBS00566

TBWT1480E

|

|

|

DTC P2101 ELECTRIC THROTTLE CONTROL FUNCTION EC-605 [VQ35DE] C D E F G H I J K L M A EC Wiring Diagram NBS00566 TBWT1480E |