Infiniti M35/M45 Y50. Manual - part 494

DTC P0455 EVAP CONTROL SYSTEM

EC-449

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

8.

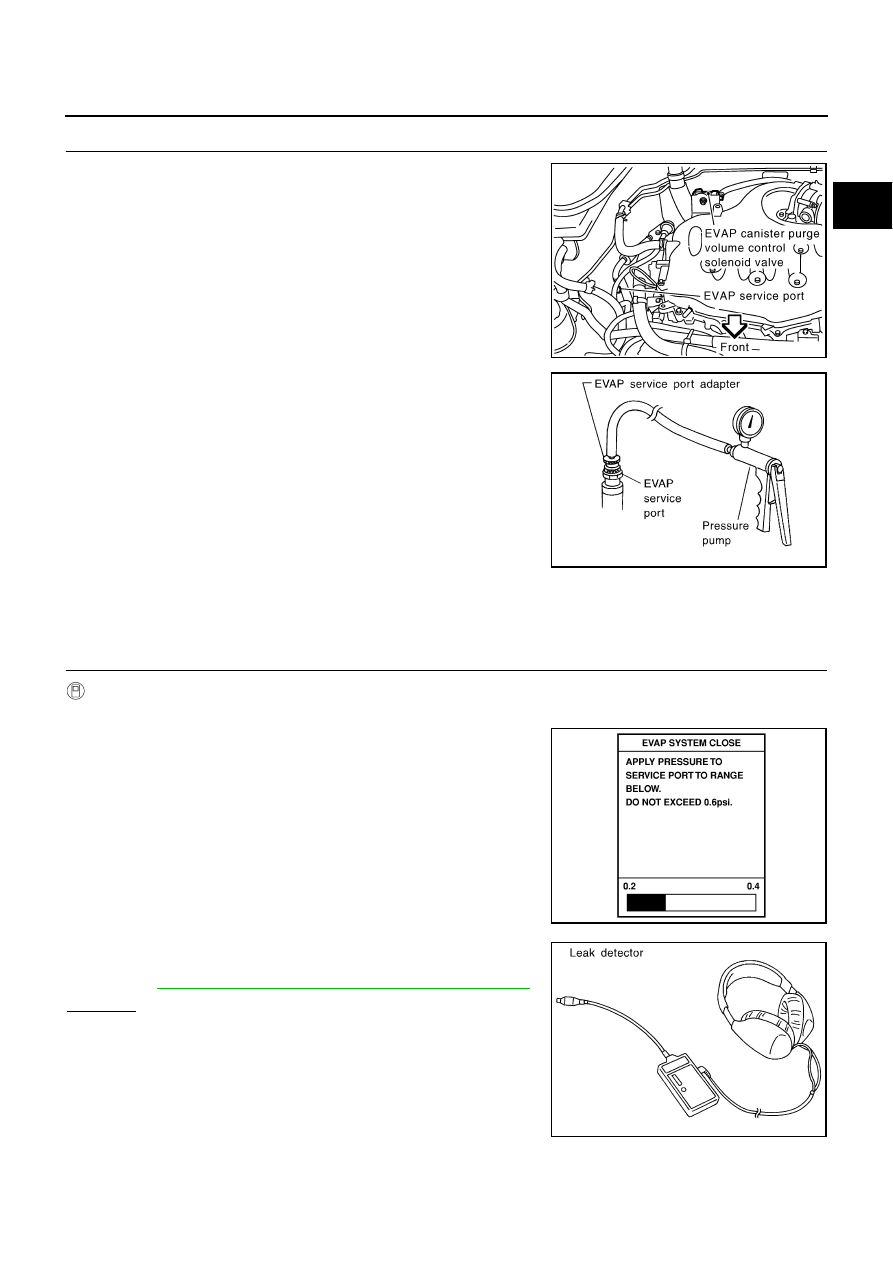

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EVAP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-II>>GO TO 9.

Without CONSULT-II>>GO TO 10.

9.

CHECK FOR EVAP LEAK

With CONSULT-II

1.

Turn ignition switch ON.

2.

Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode

with CONSULT-II.

3.

Touch “START” and apply pressure into the EVAP line until the

pressure indicator reaches the middle of the bar graph.

CAUTION:

●

Do not use compressed air or a high pressure pump.

●

Do not exceed 4.12 kPa (0.042 kg/cm

2

, 0.6 psi) of pres-

sure in the system.

4.

Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the instruction manual for more details.

Refer to

EC-40, "EVAPORATIVE EMISSION LINE DRAWING"

OK or NG

OK

>> GO TO 11.

NG

>> Repair or replace.

PBIB2006E

SEF916U

PEF917U

SEF200U