Infiniti M35/M45 Y50. Manual - part 476

DTC P0340, P0345 CMP SENSOR (PHASE)

EC-377

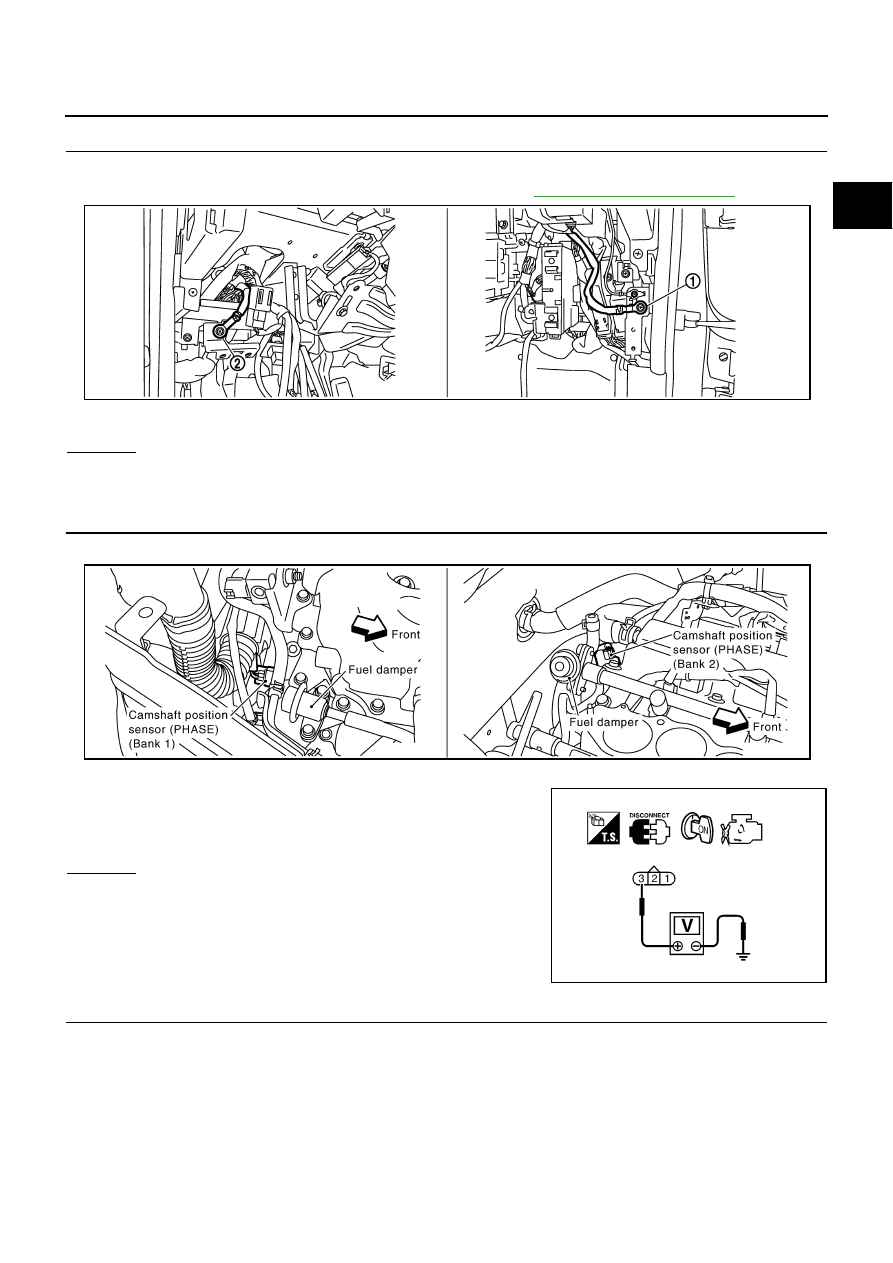

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

2.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Loosen and retighten ground two screws on the body. Refer to

.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace ground connections.

3.

CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

1.

Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

2.

Turn ignition switch ON.

3.

Check voltage between CMP sensor (PHASE) terminal 3 and

ground with CONSULT-II or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors E108, M15

●

Harness connectors F102, M72

●

Harness for open or short between camshaft position sensor (PHASE) and ECM

●

Harness for open or short between camshaft position sensor (PHASE) and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

1.

Body ground M70

2.

Body ground M16

PBIB2782E

Voltage: Battery voltage

PBIB1568E

SEF481Y