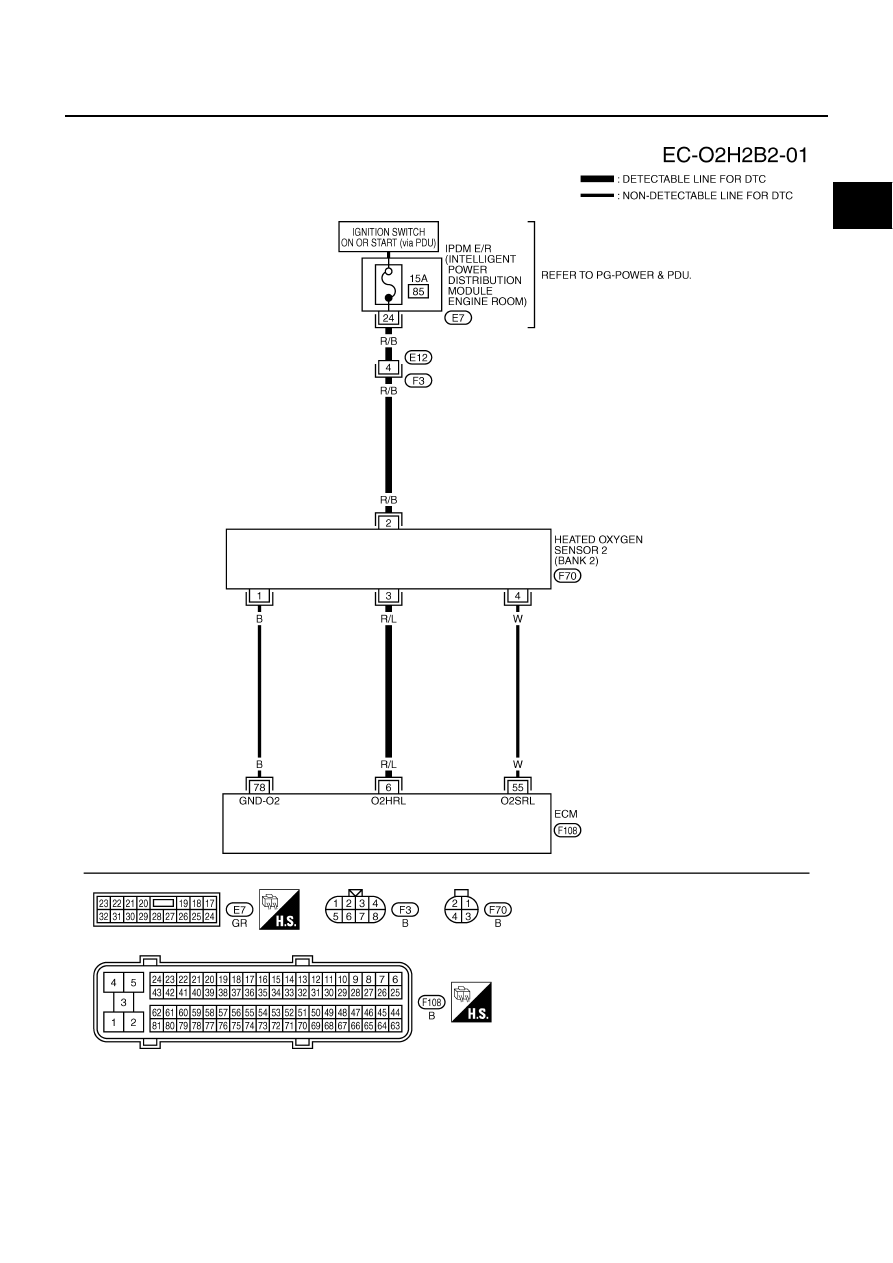

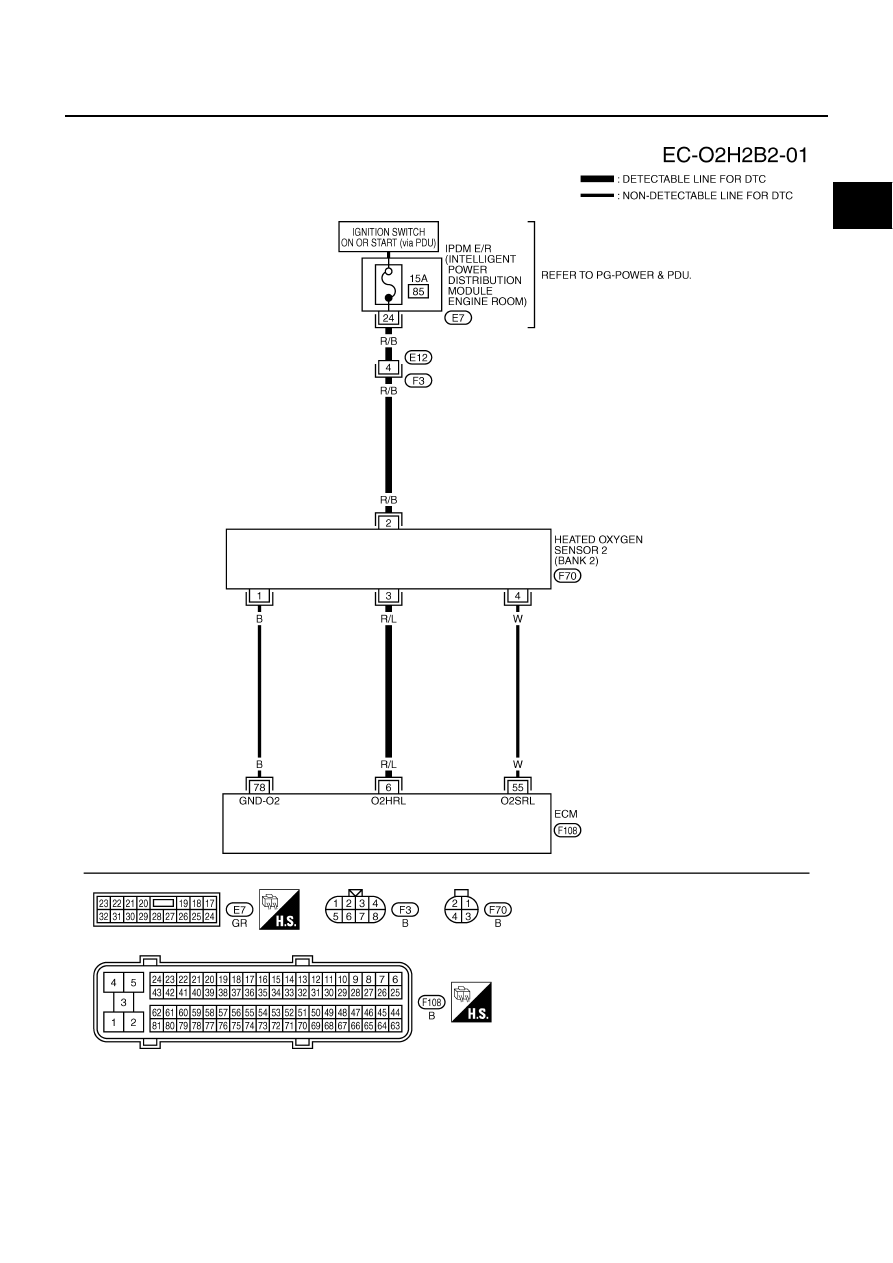

Infiniti M35/M45 Y50. Manual - part 427

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

EC-181

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

BANK 2

TBWT1471E

|

|

|

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER EC-181 [VQ35DE] C D E F G H I J K L M A EC BANK 2 TBWT1471E |