Infiniti M35/M45 Y50. Manual - part 393

EVAPORATIVE EMISSION SYSTEM

EC-45

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

3.

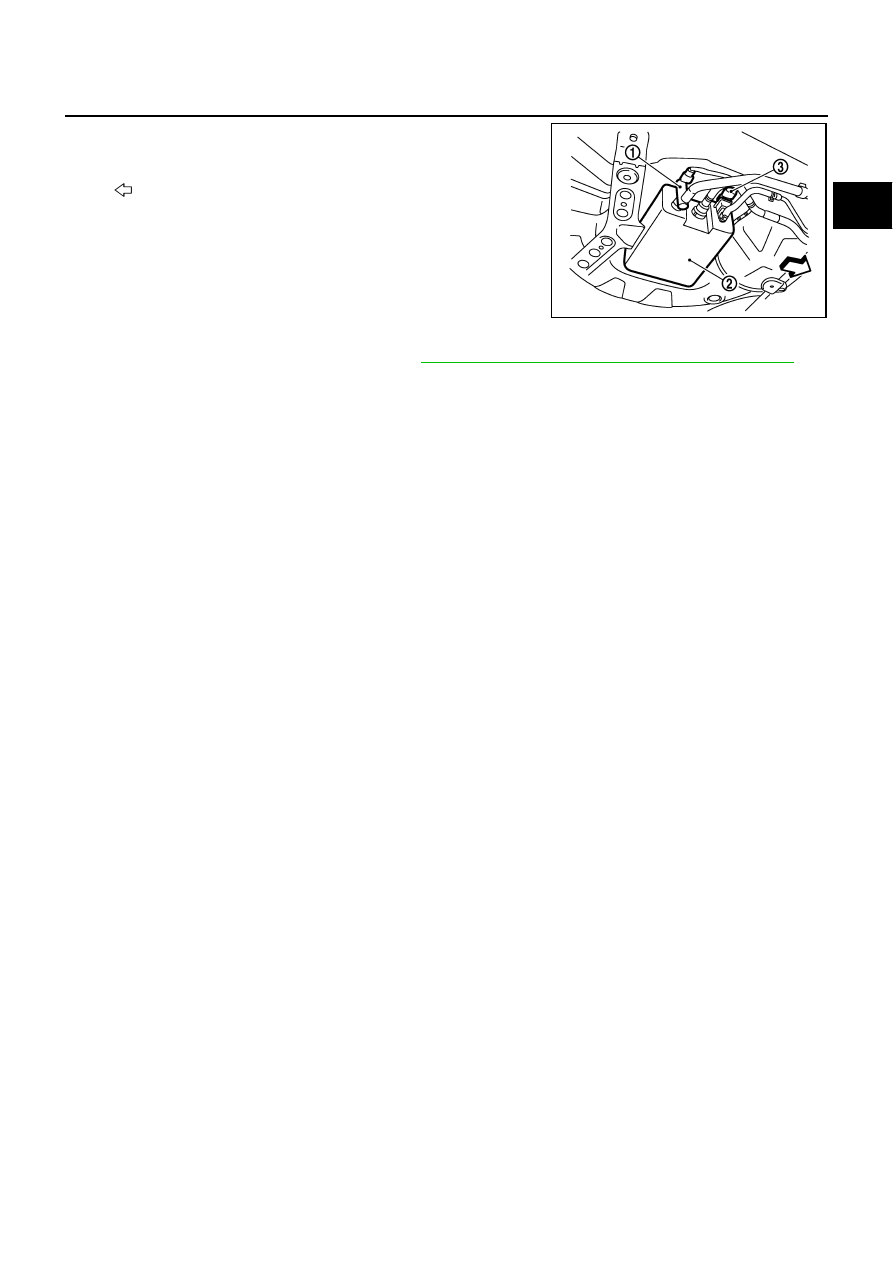

Apply battery voltage between the terminals of EVAP canister

vent control valve (1) to make a closed EVAP system.

●

Illustration shows the view from under the vehicle

●

: Vehicle front

●

EVAP canister (2)

●

EVAP control system pressure sensor (3)

4.

To locate the leak, deliver positive pressure to the EVAP system

until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to

0.028 kg/cm

2

, 0.2 to 0.4 psi).

5.

Remove EVAP service port adapter and hose with pressure

pump.

6.

Locate the leak using a leak detector. Refer to

EC-40, "EVAPORATIVE EMISSION LINE DRAWING"

PBIB2702E