Infiniti M35/M45 Y50. Manual - part 389

PREPARATION

EC-29

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Commercial Service Tools

NBS004S1

Tool name

(Kent-Moore No.)

Description

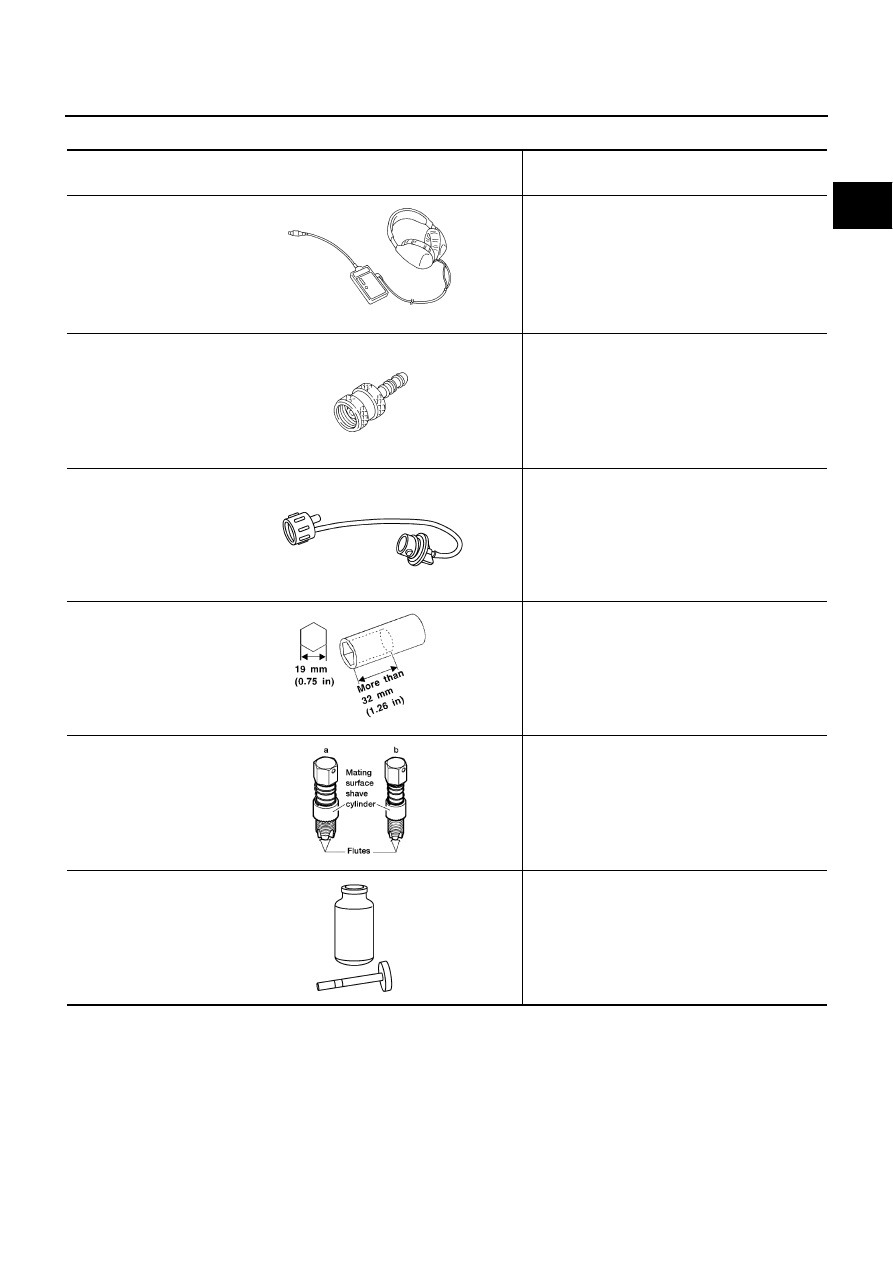

Leak detector

i.e.: (J-41416)

Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD)

Applying positive pressure through EVAP service

port

Fuel filler cap adapter

i.e.: (MLR-8382)

Checking fuel tank vacuum relief valve opening

pressure

Socket wrench

Removing and installing engine coolant

temperature sensor

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12)

Reconditioning the exhaust system threads

before installing a new oxygen sensor. Use with

anti-seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for

Zirconia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for

Titania Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM

133AR or equivalent

meeting MIL

specification MIL-A-

907)

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

S-NT703

S-NT704

S-NT815

S-NT705

AEM488

S-NT779