Infiniti M35/M45 Y50. Manual - part 324

REAR DISC BRAKE

BR-31

C

D

E

G

H

I

J

K

L

M

A

B

BR

Disassembly and Assembly of Brake Caliper Assembly

NFS000SL

NOTE:

Do not remove torque member, pads, shims, shim cover, and pad retainers when disassembling and assem-

bling cylinder body assembly.

DISASSEMBLY

1.

Remove sliding pin bolt, and then remove cylinder body from torque member.

CAUTION:

Do not drop pads, shims, shim cover and pad retainers from torque member.

2.

Remove sliding pin boots from torque member.

3.

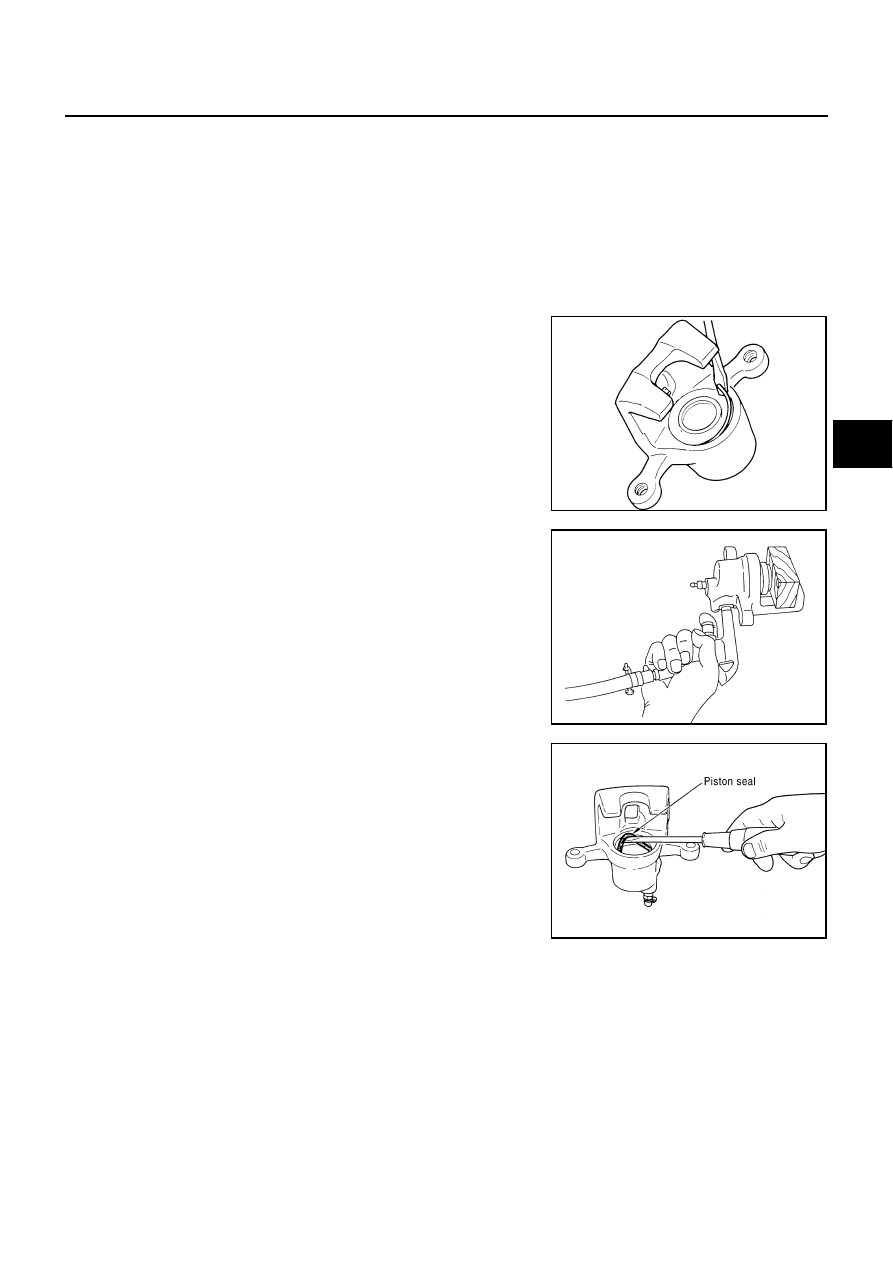

Remove retaining ring from cylinder body using a flat-bladed

screwdriver as shown in the figure.

4.

Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove piston and piston boot.

CAUTION:

Do not get fingers caught in the piston.

5.

Remove piston seal from cylinder body using a flat-bladed

screwdriver.

CAUTION:

Be careful not to damage a cylinder inner wall.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, wear, and damage. If a malfunction is detected, replace cylinder

body.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check torque member for wear, cracks, and damage. Replace if there are.

Piston

Check the piston surface for corrosion, wear, and damage. If a malfunction is detected, replace applicable

part.

SBR028A

BRD0041D

SFIA2277E