Infiniti M35/M45 Y50. Manual - part 319

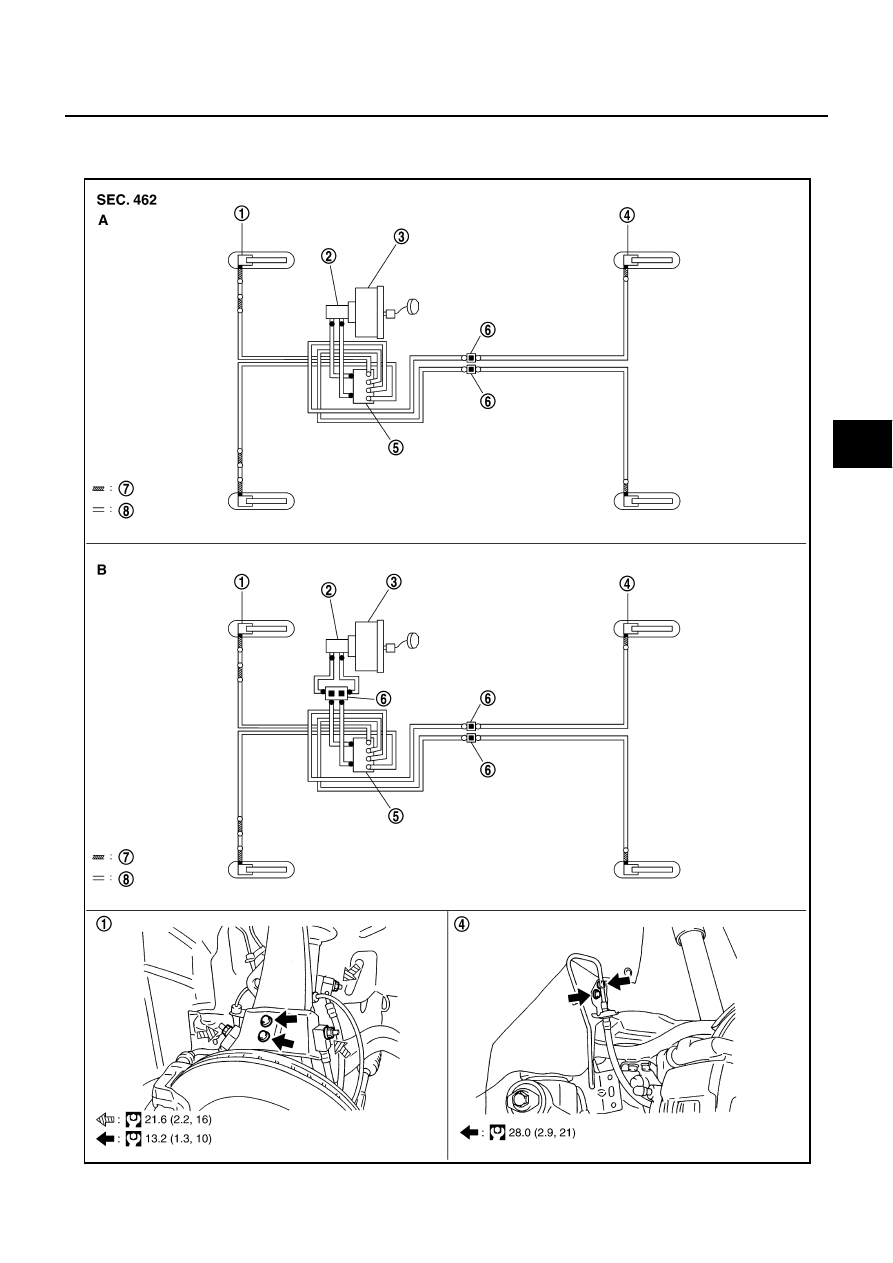

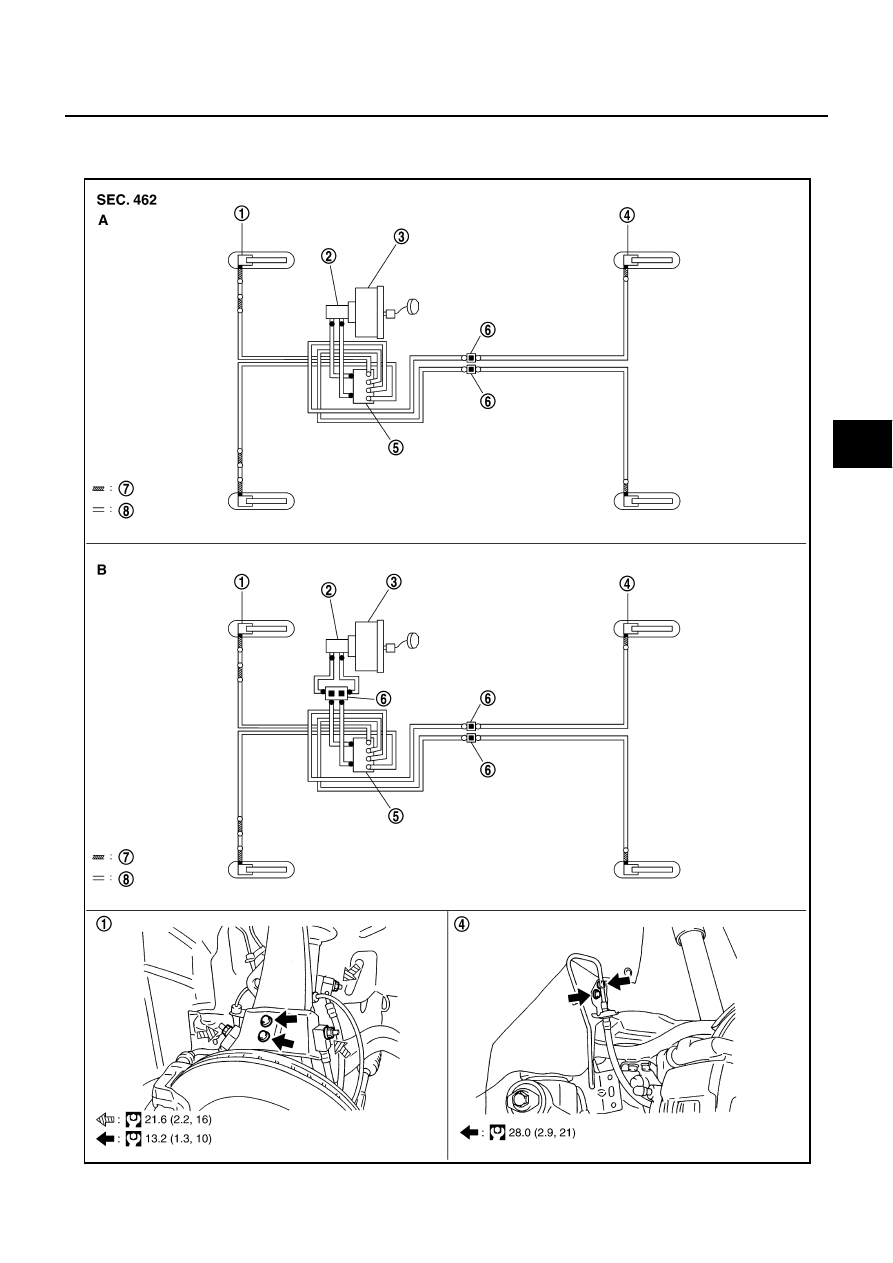

BRAKE TUBE AND HOSE

BR-11

C

D

E

G

H

I

J

K

L

M

A

B

BR

BRAKE TUBE AND HOSE

PFP:46300

Hydraulic Circuit

NFS000RZ

SFIA3096E

|

|

|

BRAKE TUBE AND HOSE BR-11 C D E G H I J K L M A B BR BRAKE TUBE AND HOSE PFP:46300 Hydraulic Circuit NFS000RZ SFIA3096E |