Infiniti M35/M45 Y50. Manual - part 138

TROUBLE DIAGNOSIS

ATC-103

C

D

E

F

G

H

I

K

L

M

A

B

ATC

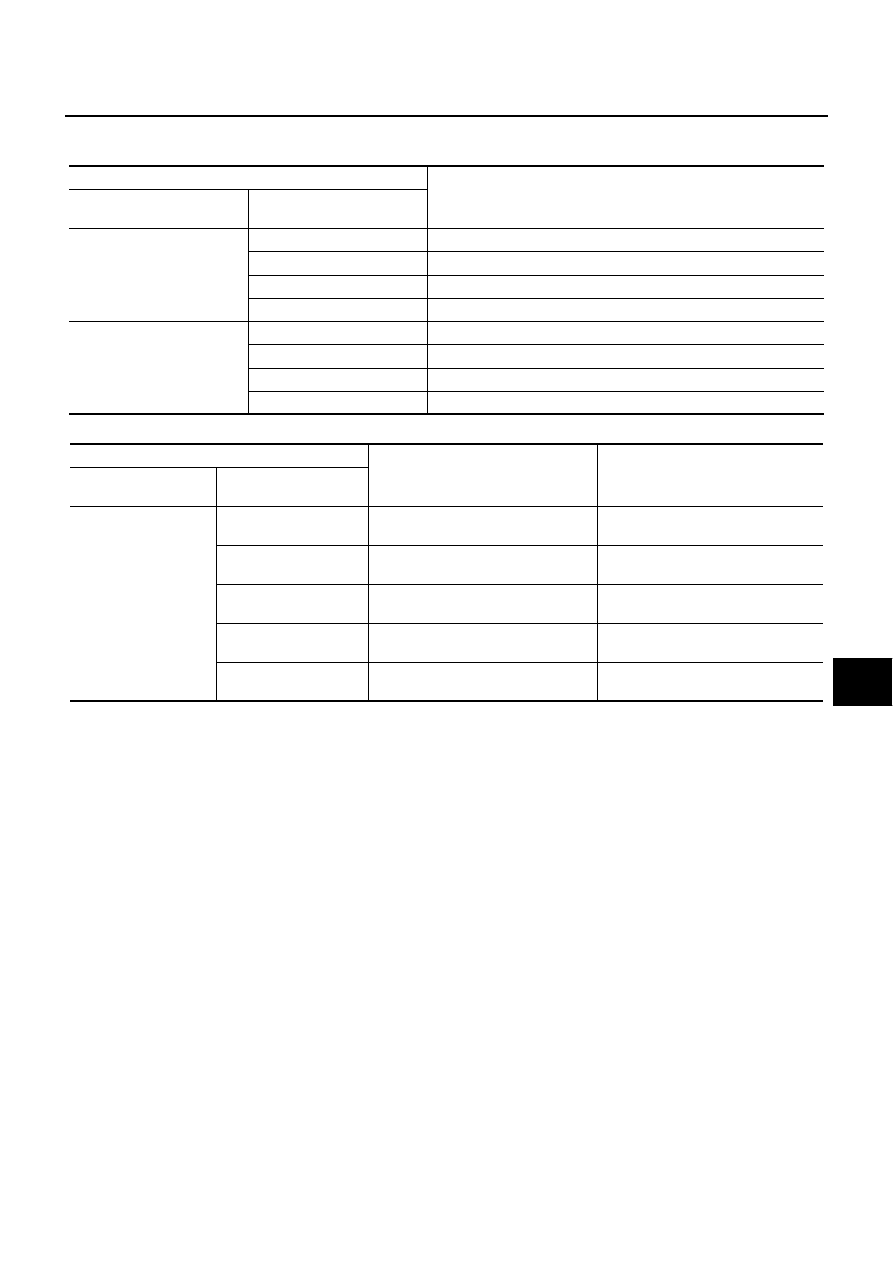

Test Reading (VK45DE)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°

C (

°

F)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 60

20 (68)

6.0 - 7.4 (43 - 45)

25 (77)

8.9 - 10.6 (48 - 51)

30 (86)

12.5 - 14.6 (55 - 58)

35 (95)

16.7 - 19.4 (62 - 67)

60 - 70

20 (68)

7.4 - 8.7 (45 - 48)

25 (77)

10.6 - 12.2 (51 - 54)

30 (86)

14.6 - 16.7 (58 - 62)

35 (95)

19.4 - 22.1 (67 - 72)

Ambient air

High-pressure (Discharge side)

kPa (kg/cm

2

, psi)

Low-pressure (Suction side)

kPa (kg/cm

2

, psi)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 70

20 (68)

907 - 1,106

(9.3 - 11.3, 131.5 - 160.4)

192 - 238

(2.0 - 2.4, 27.8 - 34.5)

25 (77)

987 - 1,207

(10.1 - 12.3, 143.1 - 175.0)

210 - 262

(2.1 - 2.7, 30.5 - 38.0)

30 (86)

1,072 - 1,312

(10.9 - 13.4, 155.4 - 190.2)

233 - 284

(2.4 - 2.9, 33.8 - 41.2)

35 (95)

1,168 - 1,425

(11.9 - 14.5, 169.4 - 206.6)

258 - 320

(2.6 - 3.3, 37.4 - 46.4)

40 (104)

1,272 - 1,550

(13.0 - 15.8, 184.4 - 224.8)

288 - 356

(2.9 - 3.6, 41.8 - 51.6)