Content .. 1139 1140 1141 1142 ..

Infiniti M35/M45 Y50. Manual - part 1141

TIRE PRESSURE MONITORING SYSTEM

WT-11

C

D

F

G

H

I

J

K

L

M

A

B

WT

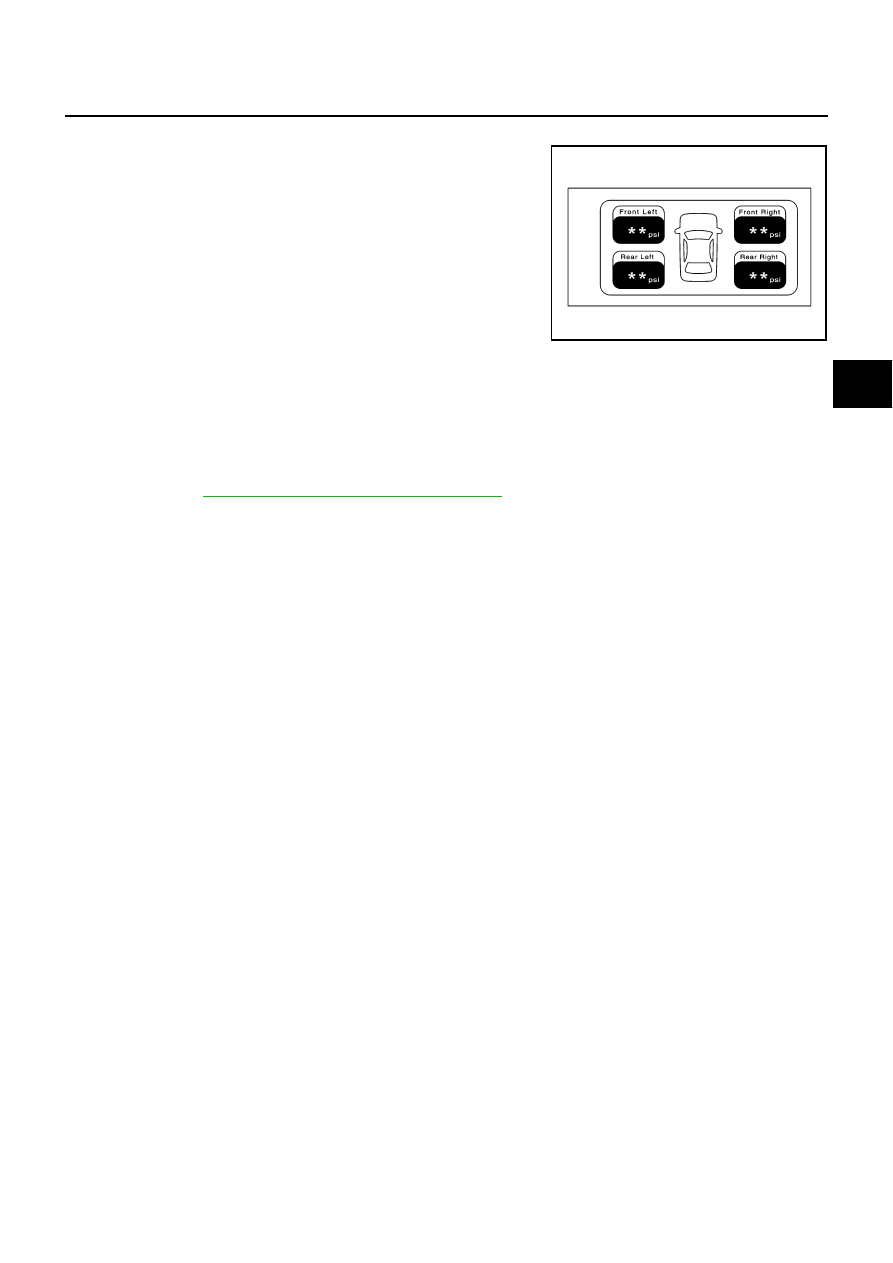

DISPLAY UNIT

Display the air pressure of each tire.

●

After the ignition switch is turned ON, the pressure values are

not be displayed until the data of wheels stabilizes.

Can Communication

NES000KV

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer to

LAN-50, "CAN System Specification Chart"

SEIA0651E