Infiniti M35/M45 Y50. Manual - part 89

TRANSMISSION ASSEMBLY

AT-279

D

E

F

G

H

I

J

K

L

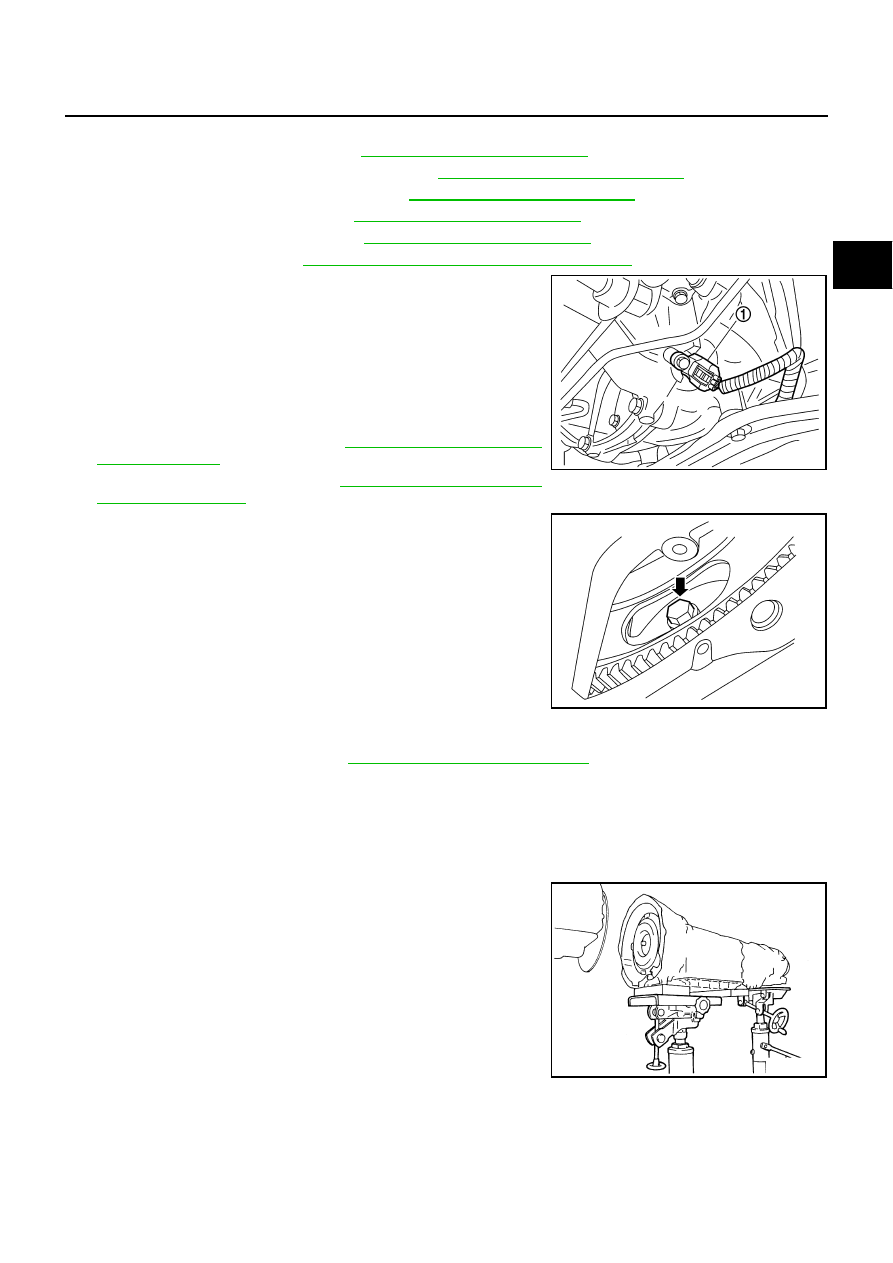

M

A

B

AT

5.

Remove heat insulator.

6.

Remove rear propeller shaft. Refer to

PR-8, "Removal and Installation"

.

7.

Remove front cross bar with power tool. Refer to

FSU-27, "Removal and Installation"

.

8.

Remove exhaust mounting bracket. Refer to

EX-5, "Removal and Installation"

.

9.

Remove three way catalyst. Refer to

EX-5, "Removal and Installation"

10. Remove front propeller shaft. Refer to

PR-5, "Removal and Installation"

.

11. Remove control rod. Refer to

AT-226, "Control Rod Removal and Installation"

12. Remove crankshaft position sensor (POS) (1) from A/T assem-

bly.

CAUTION:

●

Do not subject it to impact by dropping or hitting it.

●

Do not disassemble.

●

Do not allow metal filings, etc., to get on the sensor's

front edge magnetic area.

●

Do not place in an area affected by magnetism.

13. Remove starter motor. Refer to

14. Remove rear plate cover. Refer to

.

15. Turn crankshaft, and remove the four tightening bolts for drive

plate and torque converter.

CAUTION:

When turning the crankshaft, turn it clockwise as viewed

from the front of the engine.

16. Support A/T assembly with a transmission jack.

CAUTION:

When setting the transmission jack, be careful not to allow

it to collide against the drain plug.

17. Remove rear engine mounting member with power tool.

18. Remove engine mounting insulator (rear).

19. Disconnect A/T assembly harness connector.

20. Remove air breather hose. Refer to

AT-272, "Removal and Installation"

.

21. Remove A/T fluid charging pipe from A/T assembly.

22. Remove O-ring from A/T fluid charging pipe.

23. Disconnect fluid cooler tube from the A/T assembly.

24. Plug up openings such as the A/T fluid charging pipe hole, etc.

25. Remove bolts fixing A/T assembly to engine assembly with power tool.

26. Remove A/T assembly with transfer assembly from vehicle.

CAUTION:

●

Secure torque converter to prevent it from dropping.

●

Secure A/T assembly to a transmission jack.

27. Remove transfer assembly from A/T assembly with power tool.

SCIA6506J

LCIA0335E

SCIA2203E