Infiniti M35/M45 Y50. Manual - part 80

ON-VEHICLE SERVICE

AT-243

D

E

F

G

H

I

J

K

L

M

A

B

AT

9.

Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1

→

2

→

3), and then tighten other

bolts. Tighten control valve with TCM bolts to the specified

torque. Refer to

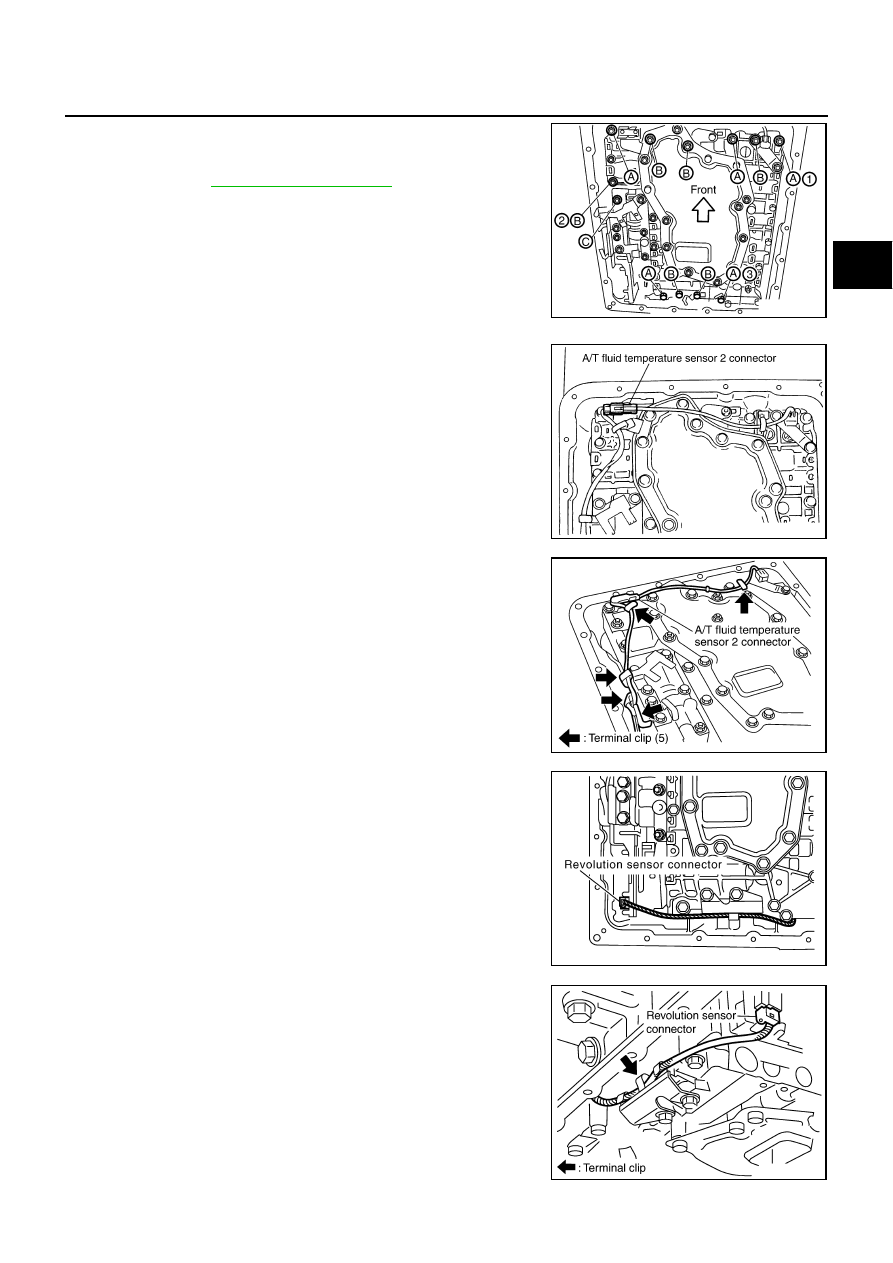

10. Connect A/T fluid temperature sensor 2 connector.

11. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clip.

SCIA5140E

SCIA5023E

SCIA5446E

SCIA7524E

SCIA7525E