Infiniti F50. Manual - part 827

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-23

C

D

F

G

H

I

J

K

L

M

A

B

WT

Inspection 2: Warning Lamp Stays On When Ignition Switch Is Turned On.

EES000DM

DIAGNOSTIC PROCEDURE

1.

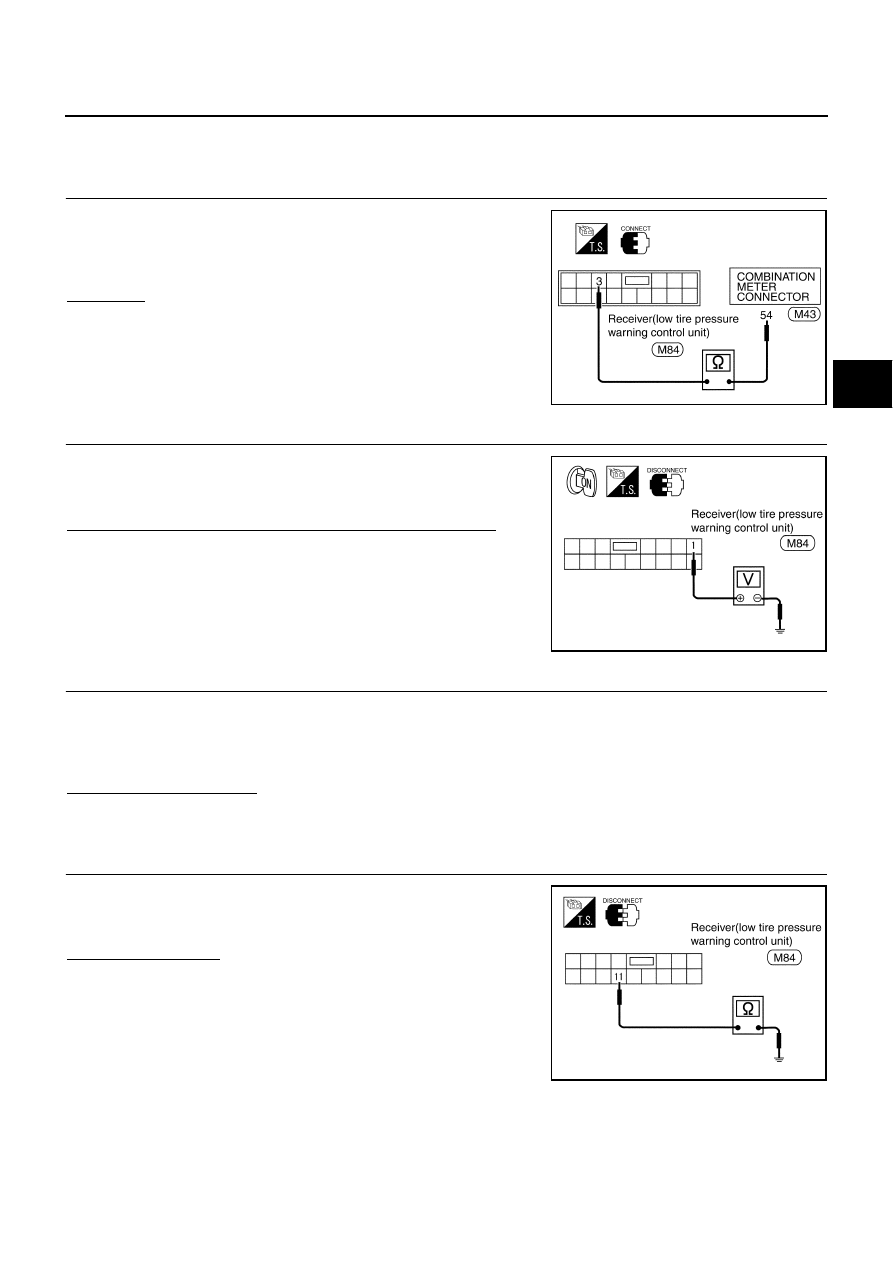

CHECK CIRCUIT

●

Disconnect combination meter connector M43.

●

Check continuity between low tire pressure warning control unit

connector (body side) terminal No.3 and combination meter con-

nector (body side) terminal No.54.

OK or NG?

OK

>> GO TO 2.

NG

>> Repair or replace harness connector.

2.

CHECK POWER SUPPLY CIRCUIT

●

Check voltage between low tire pressure warning control unit

terminal No.1 and ground.

●

Carry out self-diagnosis again.

Does battery voltage exit when ignition switch is turned “ON”?

YES

>> GO TO 3.

NO

>> Repair or replace power supply harness connector.

3.

CHECK POWER SUPPLY CIRCUIT

1.

Ignition switch is turned "ON".

2.

Check voltage between low tire pressure warning control unit terminal 2 and ground.

Does battery voltage exist?

YES

>> GO TO 4.

NO

>> Repair or replace harness connector.

4.

CHECK GROUND CIRCUIT

●

Check continuity between low tire pressure warning control unit

terminal No.11 and ground.

●

Carry out self-diagnosis again.

Does continuity exist?

YES

>> Replace low tire pressure warning control unit.

NO

>> Repair or replace ground circuit harness connector.

SEIA0060E

SEIA0058E

2 - Ground:

Battery voltage

SEIA0057E