Infiniti F50. Manual - part 601

REAR WINDOW DEFOGGER

GW-75

C

D

E

F

G

H

J

K

L

M

A

B

GW

6.

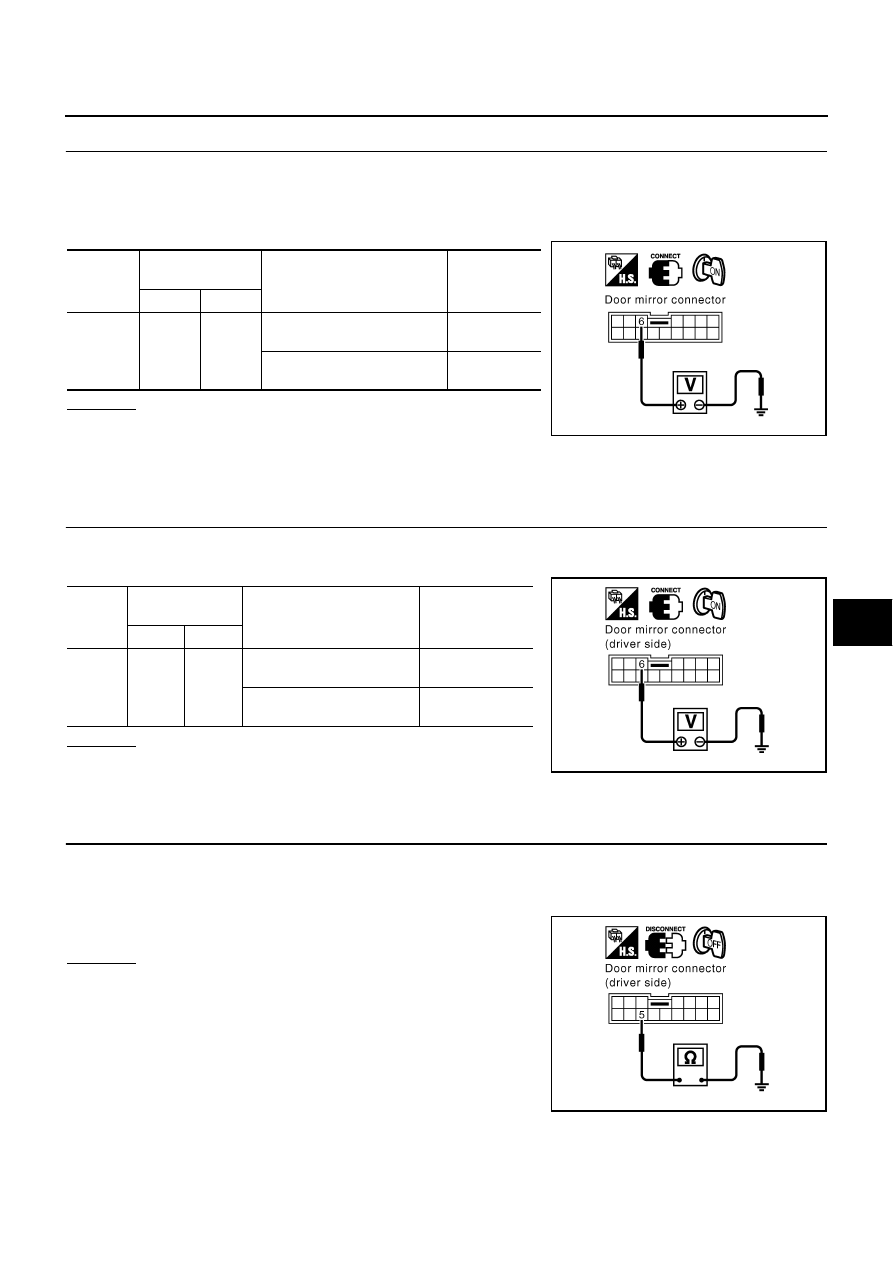

CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT

1.

Connect door mirror defogger relay.

2.

Turn ignition switch ON.

3.

Check voltage between door mirror connector D2 (driver side) or D32 (passenger side) terminal 6 and

ground.

OK or NG

OK

>> INSPECTION END.

NG

>> Repair or replace harness between malfunction door

mirror and door mirror defogger relay.

Driver Side Door Mirror Defogger Circuit Check

EIS003T3

1.

CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT

1.

Turn ignition switch ON.

2.

Check voltage between door mirror (driver side) connector and ground.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace harness between door mirror defogger

relay and door mirror (driver side).

2.

CHECK DOOR MIRROR DEFOGGER GROUND HARNESS

1.

Turn ignition switch OFF.

2.

Disconnect door mirror (driver side) connector.

3.

Check continuity between driver side door mirror defogger connector D2 terminal 5 and ground.

OK or NG

OK

>> Check the following, if it is OK, replace door mirror

(driver side).

●

Check the condition of the harness and the connector.

●

Door mirror defogger firmament continuity check.

NG

>> Repair or replace harness between driver side door mir-

ror (driver side) and ground.

Connector

Terminals

(Wire color)

Condition

Voltage [V]

(Approx.)

(+)

(–)

D2

D32

6 (L/R)

Ground

Rear window defogger switch

ON

Battery

voltage

Rear window defogger switch

OFF

0

PIIA3521E

Con-

nector

Terminal

(Wire color)

Condition

Voltage [V]

(Approx.)

(+)

(–)

D2

6(L/R)

Ground

Rear window defogger

switch ON.

Battery voltage

Rear window defogger

switch OFF.

0

PIIA3523E

5 (B) – Ground

: Continuity should exist.

PIIA3524E