Infiniti F50. Manual - part 550

CYLINDER BLOCK

EM-87

C

D

E

F

G

H

I

J

K

L

M

A

EM

Use Undersize Bearing Usage Guide

●

Use undersize (US) bearing when oil clearance with standard size main bearing is not within specification.

●

When using undersize (US) bearing, measure inner diameter of bearing installed and grind journal until oil

clearance falls within specification.

Bearing undersize table

Unit: mm (in)

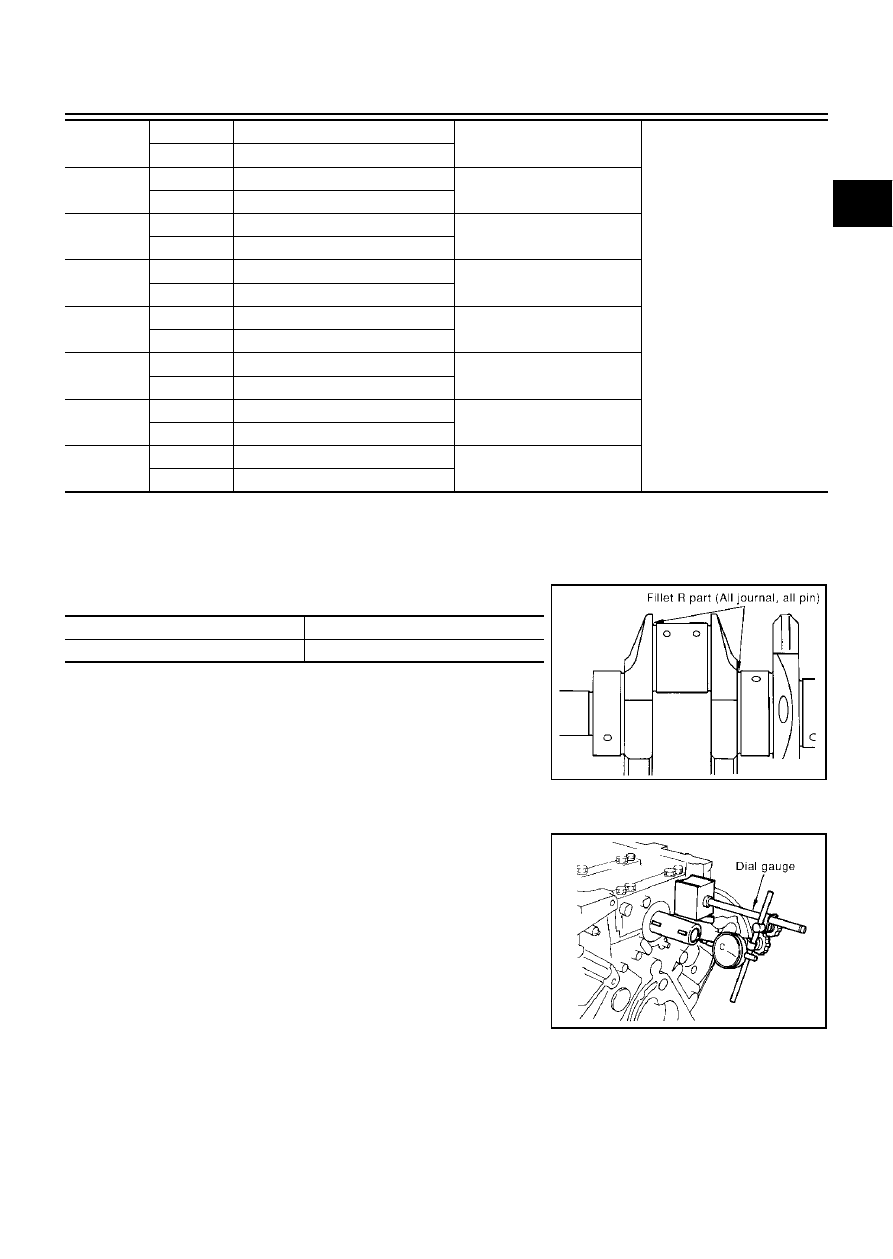

CAUTION:

Do not damage fillet R when grinding crankshaft journal in

order to use undersized bearing (All journals).

Inspection After Disassembly

EBS002MX

CRANKSHAFT END PLAY

●

Using a dial gauge, measure the clearance between the thrust

bearings and the crankshaft arm when the crankshaft is moved

fully forward or backward.

●

If the measured value exceeds the repair limit, replace the thrust

bearings, and measure again. If it still exceeds the repair limit,

replace the crankshaft also.

01

UPR

2.483 - 2.486 (0.0978 - 0.0979)

Black/Brown

Grade and color are different

for upper and lower bearings.

LWR

2.486 - 2.489 (0.0979 - 0.0980)

12

UPR

2.486 - 2.489 (0.0979 - 0.0980)

Brown/Green

LWR

2.489 - 2.492 (0.0980 - 0.0981)

23

UPR

2.489 - 2.492 (0.0980 - 0.0981)

Green/Yellow

LWR

2.492 - 2.495 (0.0981 - 0.0982)

34

UPR

2.492 - 2.495 (0.0981 - 0.0982)

Yellow/Blue

LWR

2.495 - 2.498 (0.0982 - 0.0983)

45

UPR

2.495 - 2.498 (0.0982 - 0.0983)

Blue/Pink

LWR

2.498 - 2.501 (0.0983 - 0.0985)

56

UPR

2.498 - 2.501 (0.0983 - 0.0985)

Pink/Purple

LWR

2.501 - 2.504 (0.0985 - 0.0986)

67

UPR

2.501 - 2.504 (0.0985 - 0.0986)

Purple/White

LWR

2.504 - 2.507 (0.0986 - 0.0987)

78

UPR

2.504 - 2.507 (0.0986 - 0.0987)

White/Red

LWR

2.507 - 2.510 (0.0987 - 0.0988)

Size

Thickness

US 0.25 (0.0098)

2.618 - 2.626 (0.1031 - 0.1034)

PBIC0111E

Standard

: 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Limit

: 0.30 mm (0.0118 in)

PBIC0114E