Infiniti F50. Manual - part 546

ENGINE ASSEMBLY

EM-71

C

D

E

F

G

H

I

J

K

L

M

A

EM

3.

Drain engine coolant from radiator drain plug. Refer to

CO-9, "Changing Engine Coolant"

4.

Remove the following parts:

●

Engine hood

●

Front tower bar

●

Battery

●

Air duct (inlet)

●

Air duct and air cleaner case assembly

●

Drive belts (Refer to

.)

●

Power valve vacuum tank

●

Cooling fan and tubes

●

Radiator assembly and hoses (Refer to

●

Water suction pipe

Engine room LH

5.

Disconnect engine room harness from the engine side and set it aside for easier work.

6.

Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

7.

Disconnect wire bonding exhaust manifold cover to vehicle.

8.

Disconnect vacuum hose between vehicle and engine and set it aside.

9.

Remove reservoir tank for cooling fan.

10. Remove A/C compressor from brackets, and install A/C compressor temporarily with ropes or equivalent

to avoid applying any pressures on piping or disturbing installation or removal of any vehicle parts. Refer

to

Engine room RH

11. Disconnect fuel hose at the engine side connection.

●

For disconnection/connection of quick connector, refer to

EM-31, "Removal and Installation"

12. Disconnect engine room harness from the engine side and set it aside for easier work.

13. Disconnect wire bonding exhaust manifold cover to vehicle.

14. Disconnect vacuum hose between vehicle and engine and set it aside.

15. Disconnect reservoir tank for power steering from engine and move it aside for easier work.

16. Move away relay case.

Vehicle underbody

17. Disconnect power steering oil pump from engine. Move it from its location and secure with a rope for eas-

PS-23, "POWER STEERING OIL PUMP"

18. Remove pipe of cooler for automatic transmission.

19. Remove exhaust front tube.

20. Disconnect steering lower joint, and release steering shaft. Refer to

21. Disconnect propeller shaft. Refer to

●

After disconnection, plug the opening on transmission side.

Removal

22. Remove transmission assembly. Refer to

AT-296, "TRANSMISSION ASSEMBLY"

.

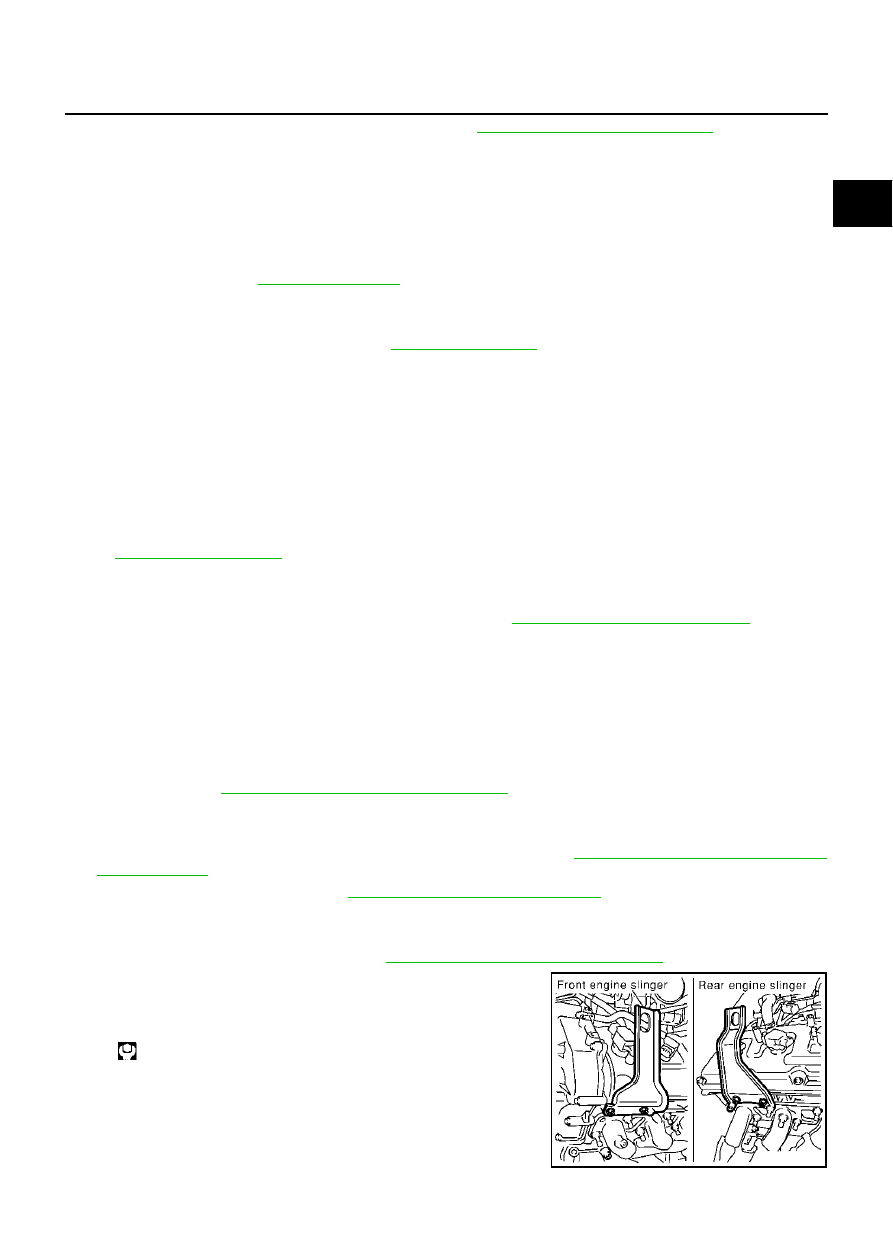

23. Install engine slingers into front of left bank cylinder head and

rear of right bank cylinder head.

24. Lift with hoist and secure the engine in position.

25. Remove engine mounting nuts on bottom surface.

26. Carefully lift up engine assembly, avoiding interference with

vehicle body, move it away and upward.

Slinger bolts:

: 30.4 - 36.3 N·m (3.1 - 3.7 kg-m, 23 - 26 ft-lb)

PBIC0082E